Highline Systems Anchors Safety Operations and Tensioning

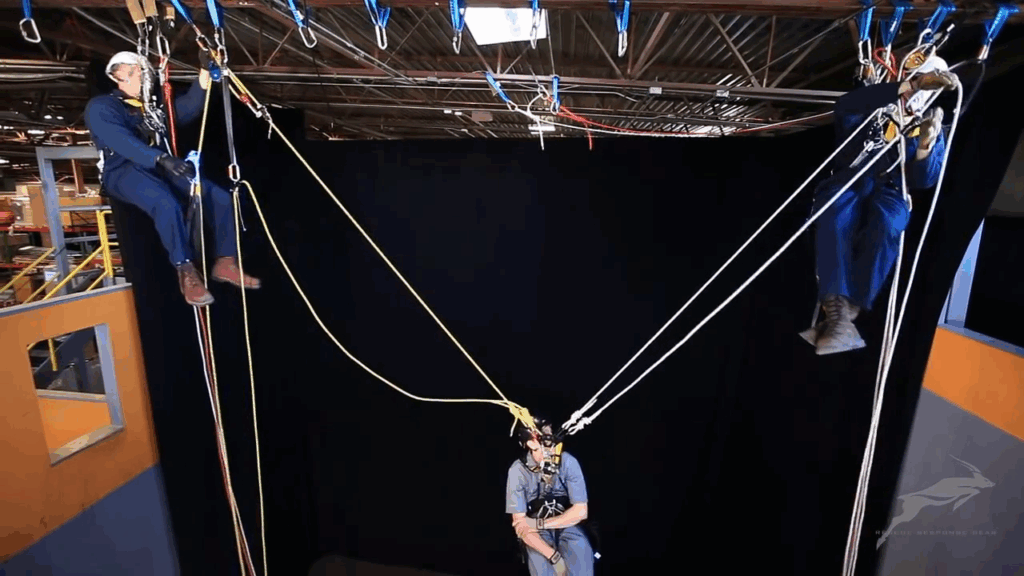

Highline systems are among the most advanced rope rescue tools. They allow teams to move patients or gear across terrain that would otherwise be impassable — spanning rivers, cliffs, gorges, collapsed structures, or even urban voids. When done correctly, highlines are efficient and controlled. When done poorly, they can overload anchors, increase risk, and endanger […]

Highline Systems Anchors Safety Operations and Tensioning Read More »