Streamlining Rope Rescue: Adopting Business Principles for Enhanced Operations

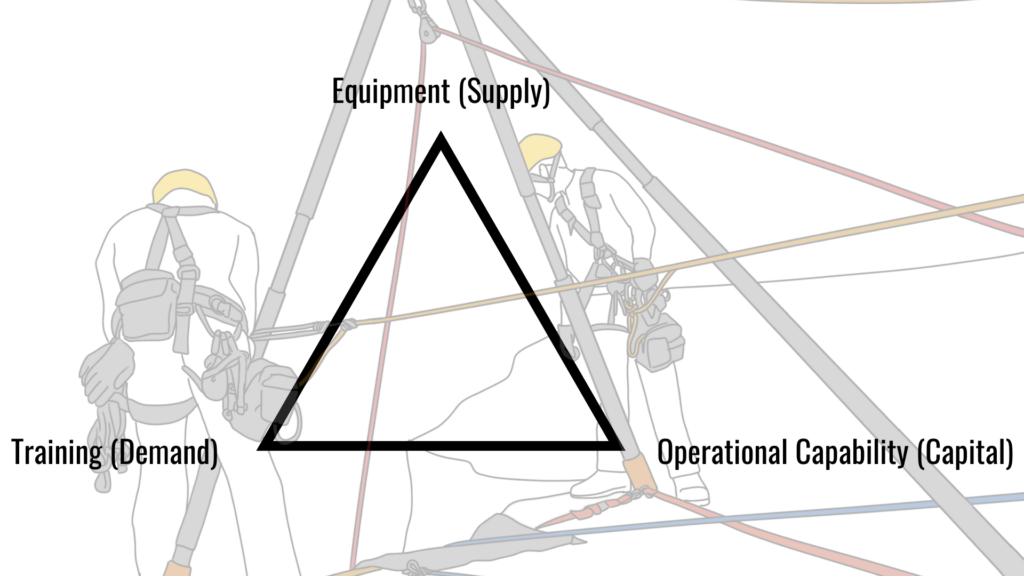

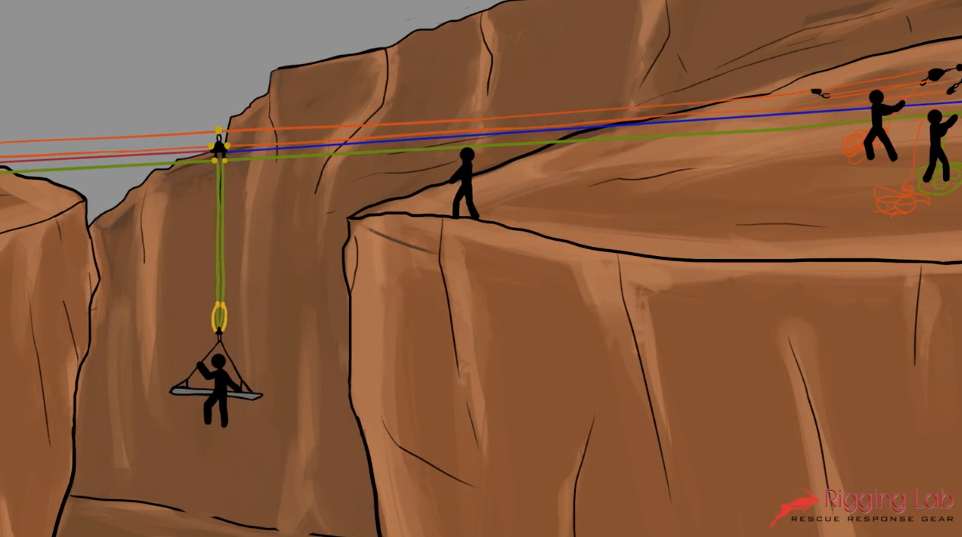

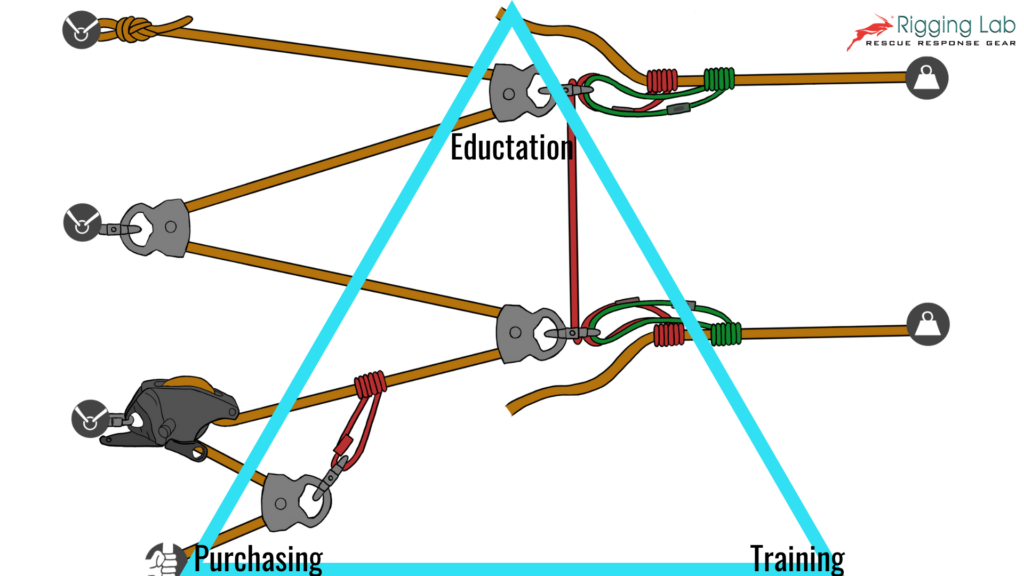

In both business and rope rescue operations, understanding the underlying forces and dynamics can profoundly affect outcomes. Typically, rescue systems are viewed through a purely technical lens—focusing on equipment and procedures. However, by adopting a business-like framework that integrates concepts similar to supply, demand, and capital, we can gain a fresh perspective that enhances our […]

Streamlining Rope Rescue: Adopting Business Principles for Enhanced Operations Read More »