Haul System Basics and the Mechanics of Pulley Systems

Haul systems form the backbone of rigging and rescue operations, using the principles of mechanical advantage to reduce the effort required to lift or move heavy loads. By integrating pulley systems into these setups, operators can achieve remarkable efficiency and safety. This guide dives deeper into the core concepts, tools, and practical applications of haul systems.

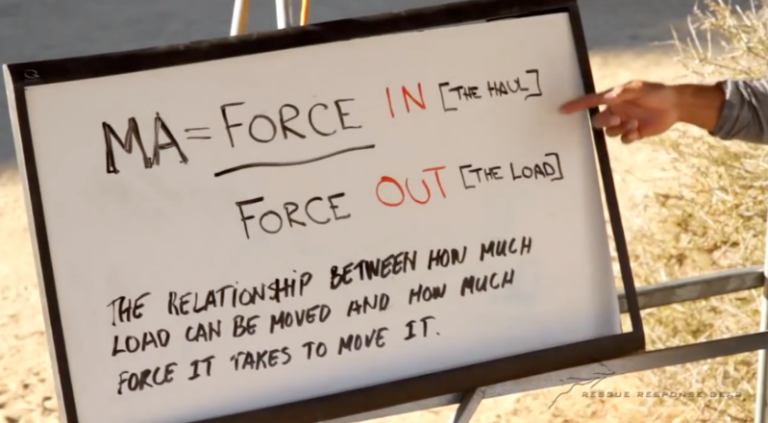

What is Mechanical Advantage and Why is it Important?

Mechanical advantage (MA) is the foundational principle that allows us to perform work—defined as applying force to move an object—more efficiently. Whether you’re lifting a person during a rescue or raising equipment in industrial settings, MA reduces the physical burden by distributing force across a longer distance.

- The Science Behind MA:

Imagine pushing a heavy object uphill versus lifting it straight up. An incline plane reduces the force required by spreading the effort over a greater distance. The same principle applies to pulleys and levers in haul systems. - Key Benefits:

- Reduces the risk of fatigue and injury.

- Simplifies operations by making heavy loads manageable.

- Increases precision and control in rigging and rescue tasks.

|

|

|

Or another way to consider levers…

|

|

|

The Essential Role of Pulleys in Haul Systems

Pulleys are more than just wheels with ropes; they are the lifeblood of mechanical advantage systems. Their purpose is twofold: to change the direction of applied force and to reduce the amount of force needed to move a load.

|

|

Fixed Pulley Systems

A fixed pulley anchors to a stable point and changes the direction of force without providing mechanical advantage. For instance:

- Pulling down on a rope connected to a fixed pulley allows a load to rise, making the operation feel more natural due to gravity.

Example:

A flagpole system is a classic example of a 1:1 fixed pulley system, where the input force equals the load’s weight.

Movable Pulley Systems

Movable pulleys attach directly to the load, allowing the force to be divided across multiple lines. This setup reduces the effort required:

- 2:1 System: The load is evenly distributed between two rope sections, halving the required force.

- 3:1 System: Introduces additional pulleys, further decreasing the effort.

|

|

|

|

Efficiency and Practical Use

While mechanical advantage reduces effort, it comes with trade-offs:

- Increased Rope Travel: Greater distance to move the load.

- System Complexity: Adding pulleys and lines requires more precise rigging.

Simpler systems like a 3:1 haul are often preferred for their balance of ease and effectiveness, but advanced systems like 9:1 setups are invaluable for heavy or complex rescues.

|

|

|

|

|

|

|

Combination Systems (Compound Systems)

Combining fixed and movable pulleys creates highly efficient systems. For example:

- 5:1 or 9:1 Systems: These setups are used in scenarios demanding extreme lifting power, such as technical rescues or industrial rigging. The trade-off is the increased complexity and rope length required.

Endurance~Distance

Measuring Mechanical Advantage: The T-Method in Depth

The T-Method offers a simple, repeatable way to calculate mechanical advantage, even for complex systems. Here’s a detailed walkthrough:

- Assign Units of Tension:

Start with one unit of tension at the haul point. - Trace the Rope:

Follow the rope through each pulley. At every junction (pulley), add the tension from both sides of the rope. - Total the Load Tension:

Add up the units of tension reaching the load. - Calculate MA:

The mechanical advantage is the ratio of the total load tension to the haul tension.

Example:

- For a 3:1 system, tracing the rope shows that three units of tension reach the load for every unit applied at the haul.

The Trade-Offs of Mechanical Advantage

While MA systems make lifting easier, they are not without drawbacks. These trade-offs must be carefully considered during setup:

- Increased Rope Travel:

As MA increases, so does the amount of rope required. For instance, a 5:1 system requires five feet of rope to lift a load by one foot. - System Complexity:

Adding pulleys and lines increases the risk of misalignment, friction, and operational errors. - Loss of Efficiency:

Real-world pulleys have friction, reducing theoretical MA. High-quality, low-friction pulleys are essential for minimizing these losses.

Practical Applications of Haul Systems

Haul systems are versatile tools used in various fields, including:

- Technical Rescue: Safely lifting individuals or equipment in high-angle or confined space rescues.

- Industrial Rigging: Managing heavy machinery or materials in construction and manufacturing.

- Recreational Climbing: Simplifying gear transport or assisting climbers.

Examples of Real-World Systems

- 1:1 Systems: Simple setups for light loads, such as raising tools.

- 3:1 Systems: Popular in rescue operations for their balance of simplicity and efficiency.

- 9:1 Systems: Used for extremely heavy loads, such as evacuating large equipment or vehicles.

|

|

Tools of the Trade: Equipment for Haul Systems

Using high-quality equipment ensures system efficiency and safety. Some essential tools include:

- Pulleys:

- Fixed Pulleys: Ideal for anchors and direction changes.

- Movable Pulleys: Enhance MA by distributing force.

- Progress Capture Devices:

Devices like the Petzl I’D or CMC MPD ensure that progress is not lost during hauling. - Ropes:

Dynamic or static ropes tailored to load requirements and system length. - Anchor Points:

Bombproof anchors ensure the entire system’s stability.

|

|

1:1 No MA

[Time 17:14]

|

|

Why Mastering Haul Systems Matters

Understanding haul systems goes beyond theoretical knowledge. It’s about applying these principles effectively in real-world situations. By mastering MA and pulley systems, teams can:

- Reduce physical strain.

- Enhance operational safety.

- Respond more efficiently to complex challenges.

Investing time in training and practicing with various systems ensures that these tools can be deployed effectively when it matters most.

2:1 MA

[Time 19:13]

|

|

3:1 MA

[Time 20:40]

|

|

9:1 MA

[Time 22:26]

|

|

The Progression Scale

|

|

Learn More:

For in-depth tutorials, video demonstrations, and advanced rigging techniques, explore the resources at Rigging Lab Academy. Elevate your rigging expertise and gain confidence in your ability to handle any scenario.

Peace on your Days!

Lance

3 thoughts on “Haul System Basics Pulley Systems and Mechanical Advantage”

It’s enormous that you are getting thoughts from this post as well

as from our argument made at this place.

I am happy that I discovered this web site, just the right info that I was searching for! .

Pretty section of content. I just stumbled upon your weblog and in accession capital to assert that I acquire in fact enjoyed account your blog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently quickly.

Comments are closed.