Mastering Mechanical Advantage Systems: Tools for Efficient Raising and Lifting

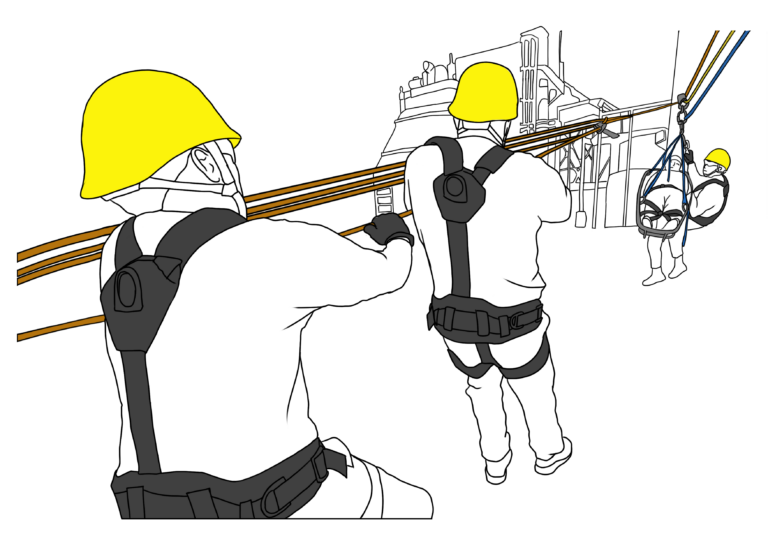

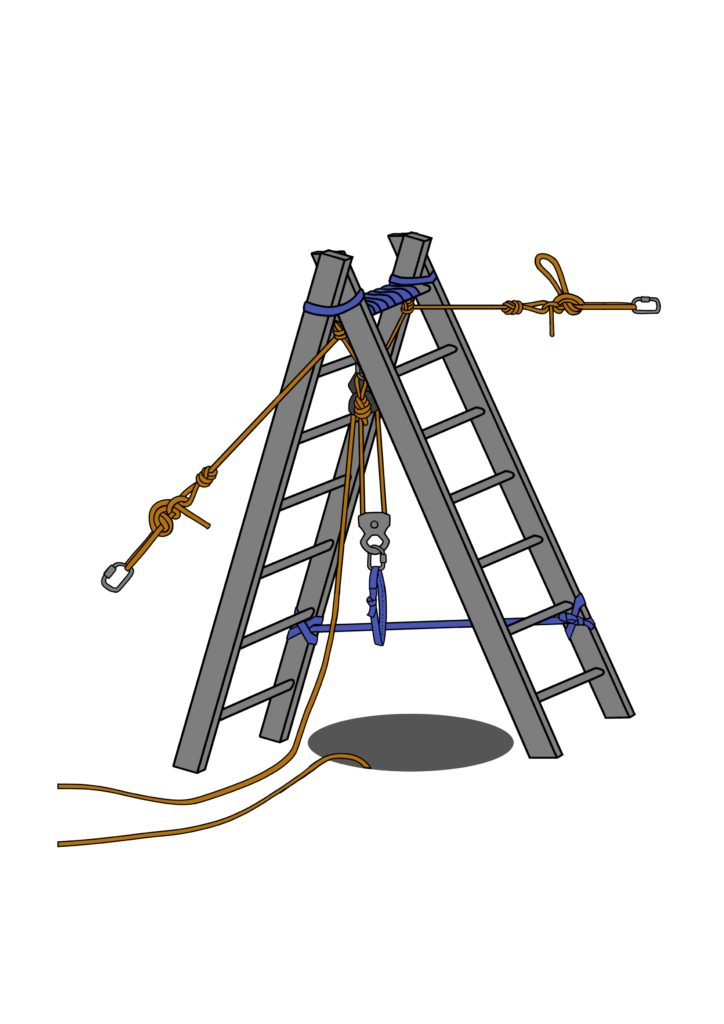

In the world of engineering and technical rescue, mechanical advantage (MA) serves as the foundation for designing systems that safely and efficiently raise or lift heavy loads. Whether it’s rescuing a patient from a vertical drop, hauling gear in wilderness settings, or performing industrial lifts, understanding and applying the principles of MA are crucial for success.

This article explores the distinctions between simple, compound, and complex mechanical advantage systems, the integration of progressive systems like 3:1, 5:1, and piggyback configurations, and the tools that make them work. By the end, you’ll have a clearer understanding of how to build, evaluate, and operate systems that prioritize safety, efficiency, and control.

Foundations of Mechanical Advantage Systems

At its core, mechanical advantage is a system’s ability to multiply the input force, making it easier to move or lift a load. This is achieved using components such as pulleys, ropes, anchors, and ratchets. Depending on the task, MA systems range from straightforward setups to intricate configurations designed for heavy loads and precise control.

Key Components of MA Systems

- Fixed Pulleys: Redirect the direction of pull without adding mechanical advantage.

- Moving Pulleys: Provide mechanical advantage by reducing the force needed to lift a load.

- Ratchets (Progress Capture Devices): Lock the rope in place to prevent slippage, ensuring safety during operation.

- Change of Direction Pulleys: Enhance system efficiency by accommodating different pulling directions.

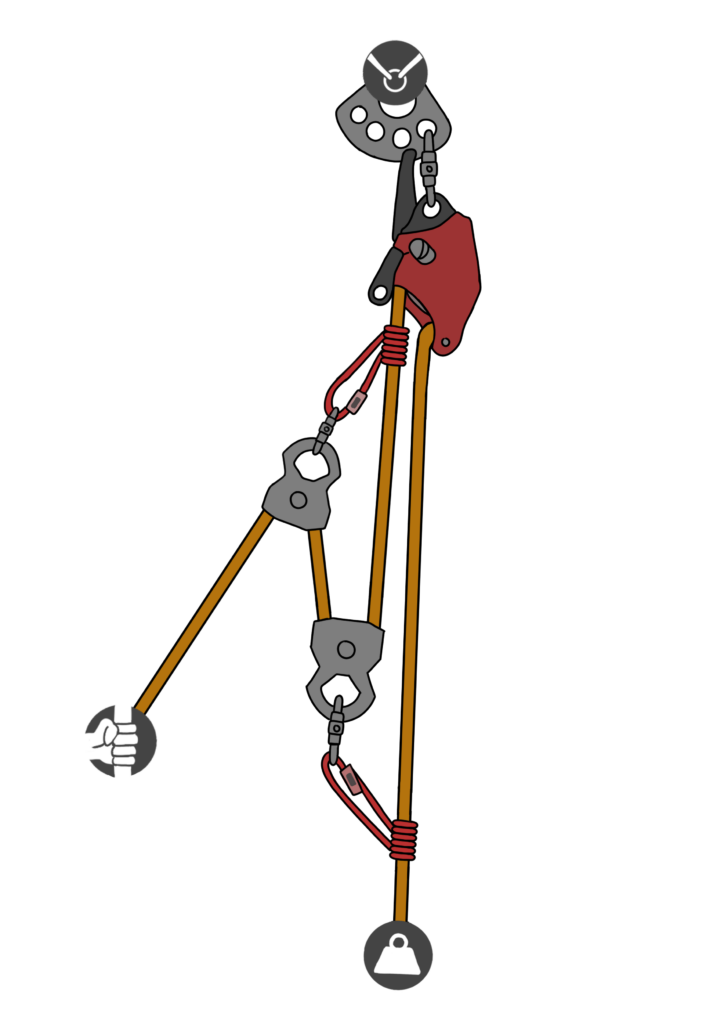

Simple Mechanical Advantage Systems

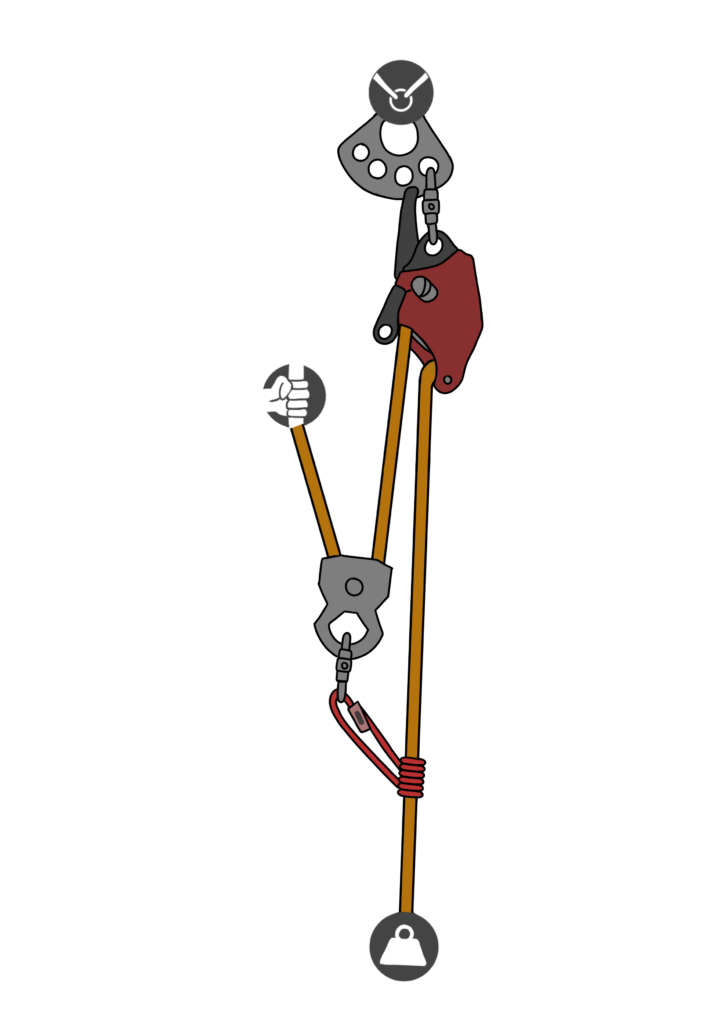

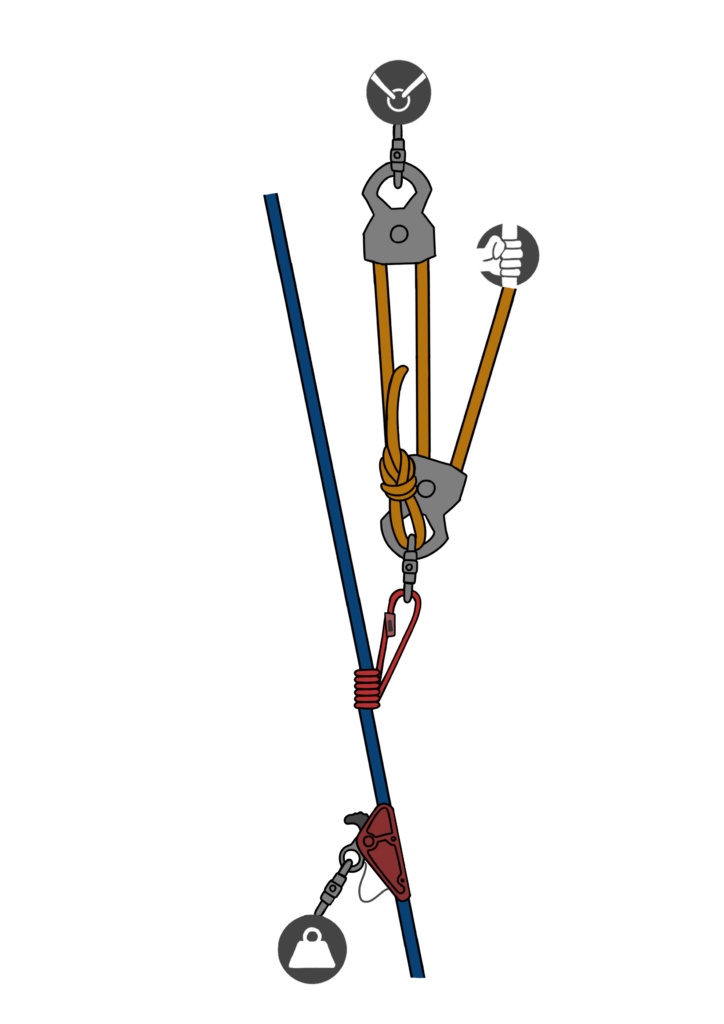

Simple MA systems are straightforward setups where all components move at the same speed and distance. A common example is the Z-Rig (3:1 MA).

Z-Rig (3:1 MA)

- A fixed pulley redirects the pull, while a moving pulley creates a 3:1 mechanical advantage.

- Ideal for basic lifting tasks where simplicity and ease of use are paramount.

Applications:

- Lowering or raising light loads.

- Quick deployment in rescue or hauling scenarios.

Learn more about building simple MA systems.

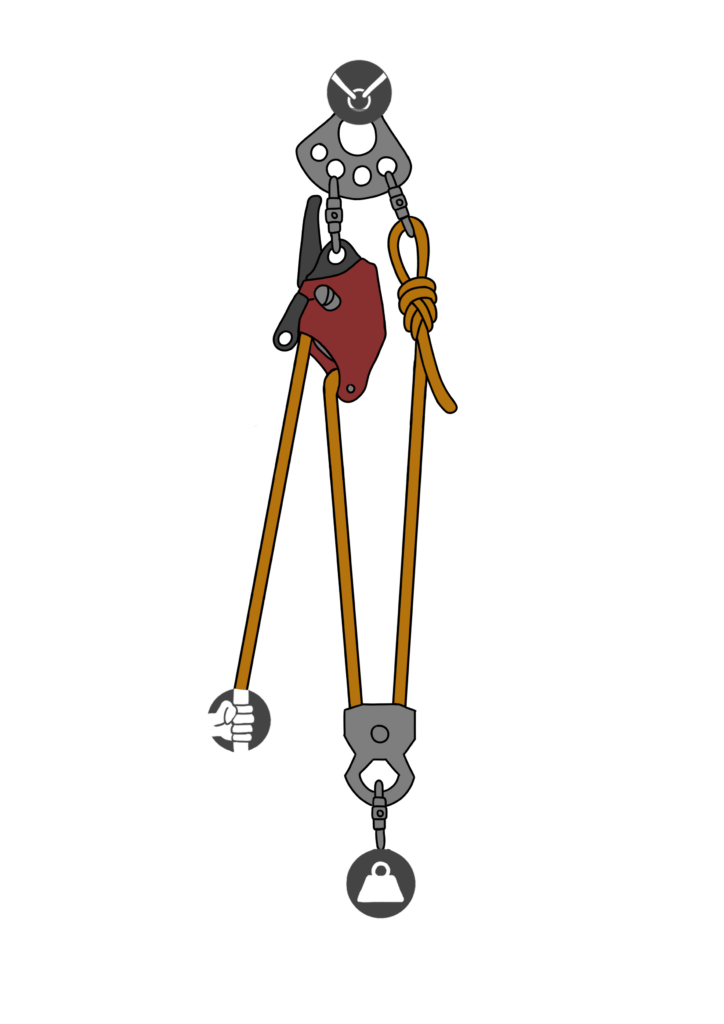

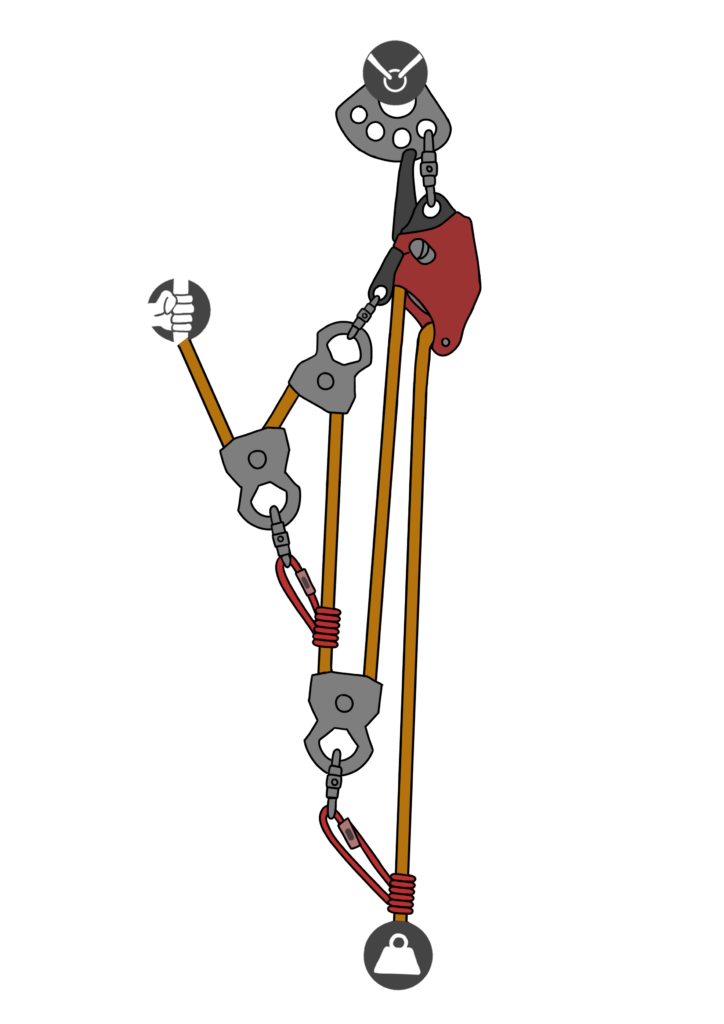

Compound Mechanical Advantage Systems

Compound systems combine two or more simple MA setups to increase the overall mechanical advantage. These systems are well-suited for heavier loads or scenarios requiring greater precision.

Examples of Compound Systems

- 6:1 MA: A 3:1 system combined with another 2:1 setup.

- 9:1 MA: Two 3:1 systems combined for maximum lifting efficiency.

Advantages:

- Greater lifting power with less physical effort.

- Versatility in handling diverse loads.

Challenges:

- Requires careful alignment of pulleys and ropes to ensure efficiency.

- Can introduce more friction and complexity compared to simple systems.

Explore compound MA system configurations.

Complex Mechanical Advantage Systems

When heavy loads and precision are non-negotiable, complex MA systems provide the solution. These setups combine multiple compound systems to achieve unparalleled lifting capability.

Advantages of Complex Systems

- Suitable for extremely heavy loads.

- Enhanced control and precision during lifting or lowering.

Challenges:

- High level of complexity in setup and operation.

- Increased equipment requirements and potential for friction losses.

Discover more about complex MA systems for advanced applications.

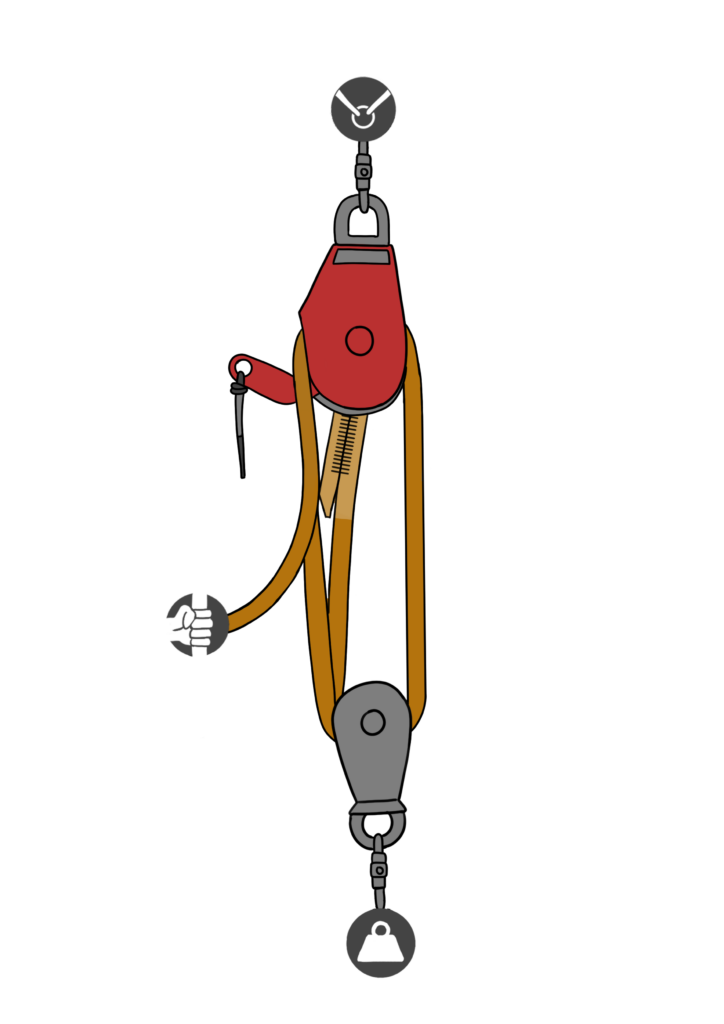

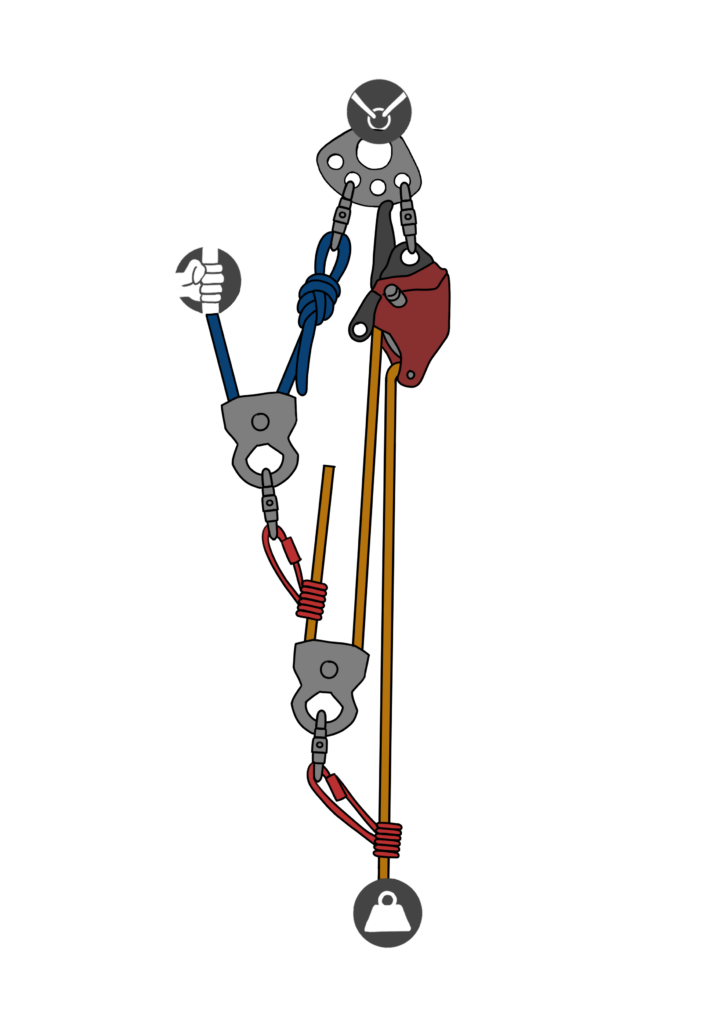

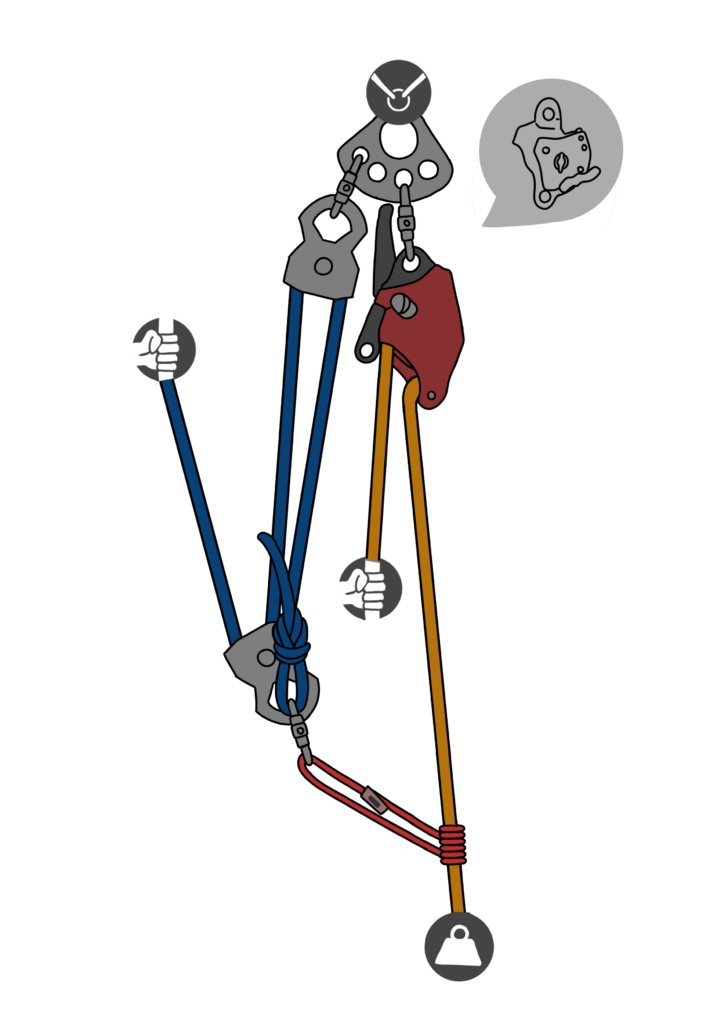

The Piggyback Pulley System

A piggyback pulley system involves integrating one MA system within another to amplify the overall mechanical advantage.

Benefits of Piggyback Systems:

- Increased Mechanical Advantage: Suitable for the heaviest loads.

- Improved Control: Dual systems allow for fine-tuned operations.

Drawbacks:

- Complexity in setup can increase error risk.

- Higher friction and equipment demands reduce efficiency.

Learn how to build and operate piggyback systems.

Balancing Efficiency and Complexity

While higher mechanical advantage reduces physical effort, it can introduce inefficiencies such as increased friction and greater complexity. The key to success is selecting the simplest system that meets the task’s requirements.

- 3:1 or 4:1 MA: Suitable for most moderate lifting tasks.

- 5:1 or 6:1 MA: Useful for heavier loads requiring more control.

- 9:1 and beyond: Reserved for the most demanding scenarios.

Evaluate your needs with our guide to MA system selection.

Conclusion: Leveraging Mechanical Advantage in the Real World

Mechanical advantage systems are powerful tools that allow rescuers and riggers to overcome challenges with precision and safety. From the simplicity of the Z-Rig to the sophistication of complex and piggyback systems, mastering these configurations ensures efficient operations in any scenario.

Understanding the principles of MA, selecting the appropriate system, and incorporating the right components can make the difference between success and failure in critical situations.

For more insights into MA systems and raising techniques, visit our comprehensive training resources.

Peace on your days,

Lance