Dynamic Forces and Shock Loading in Horizontal Track Systems

In rope rescue, most failures come from what wasn’t seen, not what wasn’t built. A system can be geometrically perfect, the anchors flawless, and the tension within the limits of every catalog rating—until motion enters the picture. Once a load begins to move, the numbers change.

Ropes stretch and rebound. Haul teams pulse instead of pull. The carriage slows or stops abruptly. That moment of movement—or loss of it—is where static calculations stop being useful.

What rescuers call shock loading is the result of sudden acceleration or deceleration inside an already-tensioned system. In vertical rope rescue, this often happens when a belay arrests a fall. In a horizontal track system, it comes from smaller, subtler actions—jerky hauling, sag adjustment, or an abrupt carriage stop. The results can be catastrophic because the base system is already under magnified force due to span length and sag geometry.

Understanding the Math

Rescue riggers start with the familiar relationship between load, sag angle, and anchor tension:

T=sinθW/2

Where:

-

T = tension in each anchor leg

-

W = total suspended load

-

θ = sag angle

This is a static equation. It assumes no motion, no elasticity, no pulse of energy.

But as soon as the line stretches or the load shifts, a Dynamic Amplification Factor (DAF) must be applied.

| Condition | Typical DAF | Approx. Increase |

|---|---|---|

| Smooth, steady haul | 1.1–1.2× | Minimal spike |

| Irregular, jerky motion | 1.5–2× | Noticeable force jump |

| Sudden stop or belay catch | 3–5× | Severe overload |

Worked Example:

A 200-lb load at a 10° sag yields roughly 575 lb static per anchor.

Multiply by the DAF, and the picture changes fast:

-

Smooth haul → 690 lb

-

Jerky haul → 1,150 lb

-

Sudden stop → 2,875 lb

That’s a fivefold jump—all from movement that lasts less than a second.

Where Dynamic Forces Originate

Static systems fail dynamically because of human rhythm and rope behavior, not mathematics.

The triggers are predictable once you know where to look.

Small Haul Teams

One or two haulers can’t keep a consistent rhythm. Each pump on the rope becomes a miniature impact. Multiply that over hundreds of feet of line, and you create a continuous series of micro-shocks.

Belay Engagement

If the mainline slips or fails and the belay catches abruptly, the resulting energy transfer is extreme. Passive belays are particularly dangerous in horizontal applications—they engage late and hard.

Carriage Stops

A carriage that hits a friction edge or comes to rest mid-span releases stored energy through the entire track in one pulse. The rope stretches, then snaps back, loading both anchors instantly.

Rope Stretch and Recovery

Even low-stretch rope elongates several percent under working load. When that elongation relaxes—through release or temperature shift—it sends force back into the system.

Mitigating Dynamic Shock

Dynamic events are controlled not by over-engineering but by movement discipline.

The smoother the operation, the smaller the amplification.

1. Increase Crew Size

A larger haul team produces continuous motion instead of pumping. Rhythm replaces shock.

2. Incorporate Progress Capture Devices (PCDs)

PCDs remove slack, prevent rollback, and allow pauses without recoil.

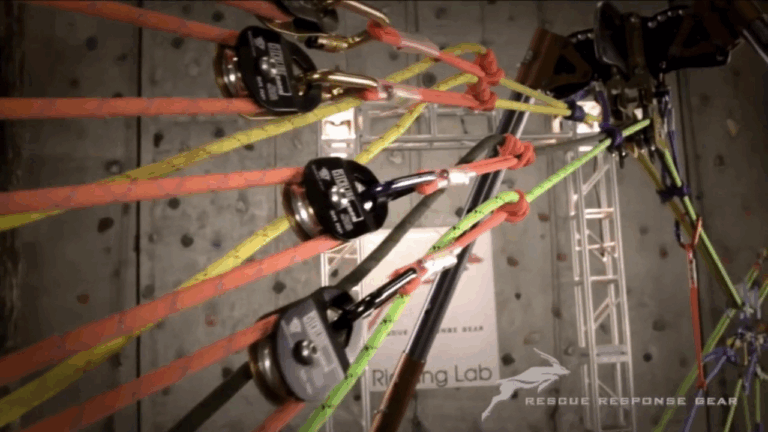

3. Use Twin-Tension Systems

Two tensioned lines share the load; when one experiences movement, the other cushions it. Forces distribute rather than concentrate.

4. Monitor Forces in Real Time

Load cells and dynamometers turn invisible energy into visible data. Crews that can see their force profile learn to adjust immediately.

5. Train for Smoothness

Rigging is rhythm. Teams should rehearse hauling as if it were choreography—steady pull, even cadence, controlled reset.

Training Drills for Force Awareness

Every principle of dynamics becomes tangible when measured.

These drills transform theory into understanding.

-

Haul Comparison – Two haulers versus six. Measure peak forces with a load cell and note how rhythm smooths the curve.

-

Carriage Stop Simulation – Move a dummy load across a span and arrest it suddenly. Observe the rebound at each anchor.

-

Belay Activation Test – Under controlled conditions, release a loaded mainline and allow the belay to catch. Compare peak to nominal force.

-

Load-Cell Familiarization – Integrate force measurement into every training event. Real data reinforces intuitive control.

Operational Best Practices

-

Minimize total weight. Move only the patient and essential gear.

-

Rig-wide, equalized anchors. Spread the energy, reduce peak per point.

-

Avoid tip belays on aerials or high directionals; they magnify torque and twist.

-

Default to twin-tension systems. Redundancy is also shock absorption.

-

Instrument your training. Make force monitoring part of standard rescue readiness.

The Physics Behind Experience

A rigger’s judgment is often faster than their calculator because experience reads motion before numbers change.

A well-built system feels “tight but alive”—it moves slightly, breathes under load, and responds predictably.

A poorly managed system feels brittle; every pull, every stop echoes through the rope.

That brittle feel is the physical sensation of dynamic energy waiting to release.

Recognizing it early lets a team correct rhythm, reposition haulers, or reset anchors before the load spikes.

Shock loads are not mysterious—they are energy misplaced in time.

Managing them means controlling acceleration, communication, and synchronization.

Key Takeaways

-

Static math defines geometry; dynamics define reality.

-

A 575 lb static anchor can momentarily experience nearly 3,000 lb under shock.

-

Human rhythm, not rope strength, decides how far that spike travels.

-

Smooth motion, large teams, and load monitoring keep systems within design limits.

-

Training with instrumentation bridges intuition and physics.

Closing Perspective

Horizontal track systems represent the frontier of rope rescue physics—long spans, light materials, and high consequence.

Every meter of rope is an elastic spring waiting for instruction.

The team’s control of motion decides whether that energy flows or explodes.

When rescuers learn to see the invisible forces—through data, through rhythm, through repetition—they transform from operators into technicians.

The difference between the two is measured not in hardware but in smoothness.

Control the motion, and the system remains stable. Lose rhythm, and even the strongest anchors can fail in silence.

Peace on your Days

Lance