Mastering the Mechanical Advantage Piggyback Method for Rope Rescue

The Mechanical Advantage Piggyback Method is a cutting-edge rigging technique designed to handle knots efficiently in rope rescue scenarios, particularly those involving mechanical devices like the Clutch or MPD. By incorporating an additional mechanical advantage system, such as an AZTEK kit, this method ensures smooth transitions and optimal safety. Here’s an in-depth guide to implementing this advanced technique.

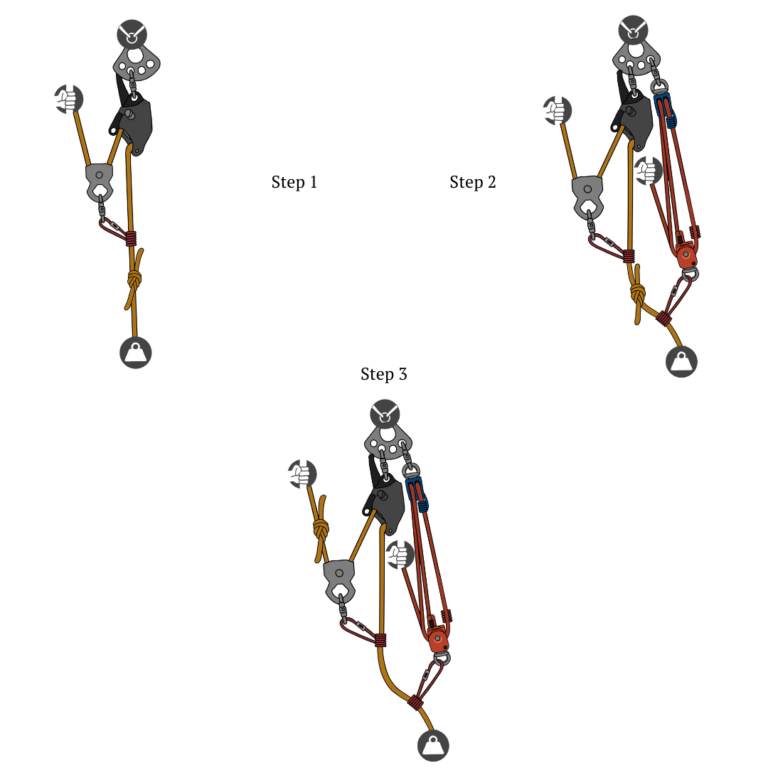

Step-by-Step Guide to the Piggyback Method

Step 1: Initial Setup and Positioning

- Prepare the Load: Begin by raising the load until the knot is positioned just below the Clutch or MPD device.

- Secure the System: Rotate the Clutch handle to the ‘Stop’ position, temporarily securing the rope and load.

- Connect the Piggyback System: Attach the piggyback system to a secure anchor point. Use a Prusik hitch to connect the secondary system to the main rope, ensuring it is ready to bear the load.

Step 2: Manipulate the Knot

- Raise Using the Piggyback System: Carefully raise the load with the piggyback system until there is sufficient clearance to pass the knot beyond the Clutch.

- Re-Rig the Rope: Detach the rope from the Clutch, reposition it so the knot is past the device, and remove any slack.

- Secure the Knot: Rotate the Clutch handle back to ‘Stop’ once the knot is successfully positioned beyond the critical point.

Step 3: Transfer Load and Resume Operation

- Transfer Load Back: Gently lower the load using the piggyback system until the tension transfers back onto the Clutch or MPD.

- Ensure Stability: Confirm the system is stable and properly loaded onto the primary device.

- Remove the Piggyback System: Detach the secondary system from the rope.

- Continue the Operation: Proceed with raising or lowering the load, now free of knots and optimally configured.

Key Advantages of the Piggyback Method

1. Efficient Knot Management

This method eliminates the disruption caused by knots, enabling smooth operations and ensuring the functionality of descent control devices like the Clutch.

2. Enhanced Safety

The secondary piggyback system provides an extra layer of control, reducing risks during critical transitions and knot handling.

3. Adaptability

Compatible with various mechanical advantage systems and devices, this method offers flexibility across different rescue scenarios and equipment types.

Applications and Best Practices

- Applications: Ideal for high-angle rescues, confined space operations, and complex rigging scenarios where knots in the rope system can pose challenges.

- Training: Mastery of the piggyback method requires hands-on practice and familiarity with the equipment. Regular scenario-based training is essential.

- Equipment Maintenance: Ensure all components, including the Clutch, Prusik hitches, and piggyback system, are in optimal condition to avoid failures during operations.

Conclusion

The Mechanical Advantage Piggyback Method is a game-changer for rope rescue teams, combining efficiency, safety, and adaptability to tackle even the most complex scenarios. By mastering this technique, rescue professionals can streamline their operations, maintain system integrity, and ensure the safety of their team and the individuals they are rescuing. Embrace this advanced method to elevate your team’s capabilities and effectiveness in critical rescue missions.

Reference Links

- Advanced Knot Passing Techniques in Rope Rescue

- Best Practices for High-Angle Rigging Systems

- Comprehensive Guide to Mechanical Advantage Systems

- Essential Gear for Complex Rope Rescue Operations

Peace on your Days

Lance