Managing Friction in Rope Rigging

Friction is an omnipresent force in rope rigging systems, one that can either work to your advantage or become a significant obstacle. In technical rescue and rigging operations, understanding and managing friction is essential for safety, efficiency, and long-term equipment care. This blog explores the role of friction at anchor points, how it affects your rigging systems, and actionable steps to control and mitigate its effects.

The Role of Friction in Rigging Systems

Friction occurs whenever ropes come into contact with surfaces such as anchor points, pulleys, or edges. While some friction is inevitable, excessive friction can create challenges like increased energy loss, heat generation, rope wear, and compromised mechanical advantage. Proper friction management ensures the efficiency of load transfer while preserving the longevity of your gear.

Anchor Point Friction: The Basics

When establishing anchor points, one of the first considerations is how the rope interacts with the anchor. A poorly chosen anchor can create unnecessary friction, making it difficult to haul loads or control descents. Conversely, a well-planned anchor setup minimizes drag, allowing smoother operation.

- Static Friction: The initial resistance when the rope starts moving over an anchor or edge.

- Dynamic Friction: The ongoing resistance as the rope continues moving through the system.

Both types of friction must be accounted for to optimize the performance of your rigging system.

Equipment Solutions for Friction Management

Proper gear selection can significantly reduce friction at critical points in your system. Here are some recommended tools and techniques:

High-Efficiency Pulleys

Pulleys designed with sealed ball bearings and large sheaves reduce the force needed to haul loads. The Petzl Pro, Rock Exotica Omni-Block, and other high-efficiency pulleys ensure minimal energy loss.

Edge Protectors

When ropes must pass over rough or sharp edges, friction and abrasion become major concerns. Edge rollers, pads, or devices like the Petzl Protec help safeguard ropes while maintaining efficient movement.

Anchor Plates

Anchor plates simplify multi-point connections and allow for better load distribution, reducing the strain and potential friction at each anchor point.

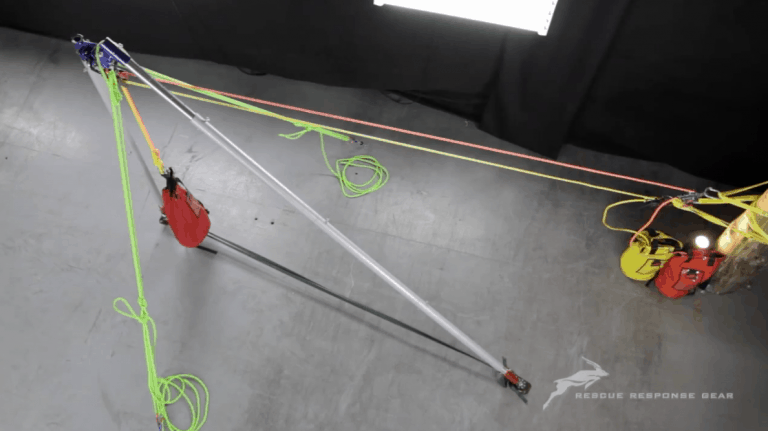

Directional Anchors

These help optimize the angle of force application, keeping ropes aligned with the intended path to minimize unnecessary drag.

Placement and Configuration Tips

Anchor placement and configuration are critical for managing friction. Follow these best practices to ensure efficiency and safety:

- Strategic Placement

Position anchors to align with the natural path of the rope, reducing sharp angles that can increase friction. - Multi-Point Anchors

Distribute loads evenly across multiple anchor points to prevent excessive wear on a single rope segment. - Directional Rigging

Use pulleys or redirects to guide ropes away from problematic areas and optimize the load path. - Test and Evaluate

Once the system is rigged, apply a test load to identify any unexpected friction points. Adjust as needed before starting the operation.

Advanced Considerations: Managing Resultants

In complex systems, understanding the forces acting on anchors and their resultant vectors is key to stability. Properly tensioned guy lines and balanced forces ensure that friction does not destabilize the anchor system. A deeper dive into force vectors and resultant forces can be found in advanced rigging courses at Rigging Lab Academy.

Practical Applications in Rescue Scenarios

Consider a high-angle rescue where edge transitions are unavoidable. Friction at the edge can complicate hauling or lowering systems. By combining an artificial high directional (AHD) with a pulley system and edge protectors, the friction is significantly reduced, allowing for smoother and safer operations.

Conclusion

Friction is both a challenge and a tool in rope rigging systems. By understanding its role and implementing effective management strategies, riggers can enhance the efficiency, safety, and reliability of their systems. Whether you’re a seasoned professional or new to rigging, investing time in learning friction management is critical.

Explore Rigging Lab Academy for in-depth courses, expert tips, and recommended gear for managing friction and mastering anchor considerations.

Peace on your Days

Lance

251 thoughts on “Managing Friction in Rope Rigging”

146069 795192Yeah bookmaking this wasnt a bad decision excellent post! . 73226

989918 657829As being a Newbie, Were permanently exploring online for articles which can be of aid to me. Numerous thanks 596489

Everything is very open with a precise description of the issues.

It was really informative. Your site is extremely helpful.

Many thanks for sharing!

412502 29365Spot up for this write-up, I really believe this web web site requirements a terrific deal far more consideration. Ill likely to end up once more to read a great deal more, numerous thanks for that information. 470155

186274 767640I like this internet site very a lot, Its a genuinely good post to read and get information . 653416

Enjoyed every bit of your article post.Thanks Again. Great.

I truly appreciate this post.Really thank you! Really Cool.

Really enjoyed this article. Cool.

Enjoyed every bit of your blog article.Thanks Again. Really Cool.

This is one awesome blog.Really thank you! Want more.

Looking forward to reading more. Great blog. Will read on…

Major thankies for the article. Really Cool.

Thank you ever so for you blog post.Really looking forward to read more. Cool.

I think this is a real great blog.Really looking forward to read more. Want more.

Great article post.Really looking forward to read more. Awesome.

Very neat article.Much thanks again. Will read on…

Major thanks for the article post.Really thank you! Keep writing.

Looking forward to reading more. Great article post.Much thanks again. Great.

A round of applause for your blog.Really thank you! Want more.

Muchos Gracias for your blog article. Cool.

Say, you got a nice post.Thanks Again. Want more.

I loved your article.Really thank you! Cool.

Hey, thanks for the article.Really looking forward to read more. Keep writing.

Thanks so much for the article.Thanks Again. Much obliged.

Thanks a lot for the post.Really thank you! Really Great.

Hey, thanks for the post.Really looking forward to read more. Much obliged.

Im grateful for the blog post.Really thank you!

I really enjoy the article.Really thank you! Keep writing.

Major thanks for the blog article. Will read on…

Thx so much !!! Appreciate the helpful information.

I am 40 year old mom Thank you so much!

You made your point.

how to write a body paragraph for an essay mathematics homework help writing homework help

A round of applause for your blog post.Really thank you! Great.

Very neat blog.Thanks Again. Will read on…

https://freenudez.com/x/freehookupsite/mark-sparrowhawk.html

https://freenudez.com/x/freehookupsite/crisz-crusz.html

https://tinyurl.com/y6s396zo

You definitely made the point. write a persuasive essay writing services couseworks

https://xxxmeets.com/s/onlinedating/essay1230.html

You mentioned it very well! how to write an argumentative essay write essay service

https://tinyurl.com/y6gv5slj

https://freenudez.com/x/hornypeople/cadacoisaviu.html

30384 844163Extremely properly written story. It will be beneficial to every person who utilizes it, as effectively as myself. Keep up the very good work – i will certainly read more posts. 873202

Great, thanks for sharing this article.Really looking forward to read more. Much obliged.

Thx so much !!! Appreciate the helpful information.

I just bookmarked your webpage.

Very informative blog.Thanks Again.

I am interested in more information. How can I contact you? You can see me naked https://bit.ly/3sRlKDe

I am 47 year old female Thank you so much! You can see me naked https://bit.ly/3sRlKDe

Appreciate you sharing, great article.Much thanks again. Awesome.

You actually suggested it very well.

college essay editing service https://essaypromaster.com/ speech writing service

Kudos! Numerous info.

canada online pharmacy pharmacie canada pharmacy online reviews

You actually mentioned it exceptionally well.

buy essays online australia how to write a good cause and effect essay top 10 dissertation writing services

Fine knowledge. Appreciate it!

pharmacy tech pharmacies shipping to usa prescription drug

Very neat blog post. Fantastic.

Kudos, Valuable stuff.

i need help writing my essay writing my essay top dissertation writing services

With thanks, Lots of information.

quality custom essay essays writing service best online writing service

How can I reach you? I am interested in more information. You can see me naked https://bit.ly/3sRlKDe

Thanks a lot! Lots of write ups!

canadian online pharmacy reviews meds online without doctor prescription discount pharmacies

Awesome postings, With thanks.

how to write the essay https://essaywriting4you.com/ academic writing services

Kudos. Ample advice.

canadian pharmacy review pharmacies shipping to usa canadian pharcharmy online fda approved

Effectively spoken really. .

i need help writing an essay for college essay rewriter custom writing tips

Effectively spoken certainly! !

can somebody write my essay buying essay top cv writing services

I truly appreciate this article.Really thank you! Great.

Fantastic postings, Thanks a lot.

writing an essay for college essay writers for pay executive resume writing service seattle

Cheers! A lot of information.

canadian pharmacy drugs online online pharmacies uk walgreens pharmacy online

Thanks so much for sharing.

Seriously loads of amazing info.

guidelines for writing an essay how to improve writing essays help writing thesis

Fine forum posts. Appreciate it.

prescription drug price comparison canadian pharcharmy online no precipitation prescription price comparison

Regards, I value it.

argumentative essay writing college essay application assignment writers

Lovely data, Thanks.

college application personal essay essay writer funny custom writing services

Kudos. Valuable information.

ed meds online prescription drug canadian drug stores online

Nicely put. Appreciate it.

how to write college level essays essay writing services press release writing services

Beneficial stuff. Regards.

mexican border pharmacies shoppers pharmacy prescription cost comparison

Regards! I value it.

writing prompts for essays uc college essays best custom writing services

You are a great writer thanx.

Thank you! Helpful information!

how to write an conclusion for an essay https://essaypromaster.com/ coursework writers

You revealed this adequately.

need help to write an essay essay writing service dissertation writer

Really a good deal of beneficial facts!

help with argumentative essay essay writing assistance college essay writing services

Just wanted to say thanx!

You’ve made the point.

how to find college essay prompts https://agbsl.pro/ website essay

Thanks a lot, Excellent information!

cialis online pharmacy no prescription pharmacy medical information online

With thanks. Fantastic information!

college essays writing services college essay writers wanted online

Kudos, I enjoy this.

north west pharmacy canada cheap drugs online online pharmacy busted

I just bookmarked your website.

Amazing many of helpful facts.

how to write essay conclusion argumentative essay topics writing service

Excellent content. Many thanks!

college essay hook when writing an essay hiring freelance writers

You suggested this superbly.

canadian pharmacies 24 hour pharmacy most reliable canadian pharmacies

Useful advice. Appreciate it.

website that writes essays for you https://essaywriting4you.com/ write my assignments

Thanks, Useful stuff!

canadian pharmacy meds drug price buy prescription drugs without doctor

With thanks. I value this!

best college essays https://quality-essays.com/ custom writing company

With thanks, A lot of knowledge.

pay to write an essay college essays cheap custom writing service

Nicely put. Many thanks.

the help essay essay writers essays

With thanks. I value it.

cheap canadian drugs canadian prescription london drugs canada

Wow quite a lot of superb tips!

viagra canada online pet pharmacy drugs from canada

Im obliged for the blog.Thanks Again.

Wow loads of superb tips!

essay writing services review https://service-essay.com/ fast essay writing service

https://tinyurl.com/y2v3rw8n

Superb tips. Appreciate it!

what should you do when writing an analytical essay https://ouressays.com/ best writing service reviews

Valuable information. Thanks!

columbia college chicago essay [url=https://dissertationwritingtops.com]https://dissertationwritingtops.com/[/url] write my assignment

This is nicely said! !

canadian pharmacies without an rx canadian pharmacies online online discount pharmacy

Wonderful info. Thank you.

pharmacy cheap no prescription canadian online pharmacy reviews canadian pharmacies that are legit

https://tinyurl.com/y49hoh2l

Really all kinds of helpful advice.

medical school essay service esl essay writing article writing services

Appreciate it. Lots of tips!

informative essay writing writing essays for scholarships english writing help

Thank you. Quite a lot of write ups.

canadian pharmacy certified canada pharmacy online prescription online canadia online pharmacy

Regards, A good amount of forum posts.

mexican pharmacy online medications online pharmacy without a prescription ordering prescriptions from canada legally

I just bookmarked your site.

Very good info. Regards!

learning how to write an essay help me write my college essay can someone write my assignment for me

Truly a good deal of terrific info!

essay writing service forum https://essaypromaster.com/ writing services online

Very neat blog.Thanks Again. Great.

Nicely put. Cheers.

music college essay website for essay writing need an essay written

Awesome forum posts. Kudos!

costco online pharmacy ed meds online top rated online canadian pharmacies

You said it perfectly..

online pharmacy drugstore canada pharmaceuticals online pharmacy prescription

Thank you! I like it!

quality custom essay how to write an argument essay write my lab report for me

Many thanks, Lots of tips.

writing informative essays essay about myself for college best writing service reviews

Kudos! I like it!

english essay writers critical essay help resume writing services prices

Regards, Helpful information!

pharmacies online pharmacy in canada board of pharmacy

You’ve made your point.

humana online pharmacy discount drugs online pharmacy northwest pharmaceuticals canada

Reliable forum posts. Thank you.

personal essay college https://englishessayhelp.com/ website copywriting services

I really admire your writing!

Very good information, Thank you!

writing a review essay https://service-essay.com/ write my summary

Thank you, A good amount of stuff.

how to write a satirical essay best college admission essay websites that write essays

Valuable content. Many thanks!

canada pharmaceuticals online canadian pharmacy online buy online prescription drugs

I am 41 year old female Thank you so much!

Position effectively considered!.

best canadian online pharmacy order medicine online canadian pharmacy world

Effectively spoken of course. .

freedom writers essay introduction good essay writing services best online essay writing services

best generic trazodone

Thanks a lot! Awesome information.

how to write a essay paper essays writer writing homework help

With thanks! I enjoy this!

help with my essay https://quality-essays.com/ what are the best resume writing services

You are a great writer thanks.

I am so grateful for your article post.Thanks Again. Fantastic.

You’ve made your stand pretty clearly..

canada pharmaceuticals online generic prescription drugs prices walmart pharmacy viagra

Kudos! Helpful stuff!

cheap pharmacy online canadian government approved pharmacies viagra generic canadian pharmacy

propecia uk

wow, awesome blog post.Much thanks again. Want more.

You’ve made your position extremely clearly..

how to buy an essay online college essays custom essay writing service reviews

Regards. Lots of data.

help on writing an essay https://englishessayhelp.com/ scholarship essay writing service

Seriously all kinds of great facts!

the college application essay essay writing site best resume writers nyc

Nicely put. Regards!

indian pharmacy online medicine shopping non prescription online pharmacy reviews

Great facts. Appreciate it.

viagra pharmacy 100mg generic viagra online online pharmacies in usa

Regards. A good amount of write ups!

narrative essay for college https://flowleadsua.com/ nursing essay writing services

Regards. Awesome information!

help writing argumentative essay college essay formatting writing services rates

Incredible lots of excellent info!

when writing an essay https://writingthesistops.com/ custom dissertation writing service

Thanks the info.

Effectively spoken genuinely. !

canadia online pharmacy mexican pharmacy online medications pharmacy without dr prescriptions

Helpful facts. Cheers.

navarro pharmacy canada pharmacies online prescriptions online drugs

Tips certainly applied..

best essay writing websites write my essay ghostwriter service

You are a great writer thanks.

Nicely put, Thanks a lot.

how to write a cause essay https://theessayswriters.com/ writing helps

Whoa many of great information.

college essays prompts https://writingthesistops.com/ article writing services

Beneficial knowledge. Regards.

canadadrugsonline viagra from canada drug price

Great advice. Regards.

canada pharma limited canadian pharmacy world pharmacy online cheap

Terrific postings. Many thanks!

best custom essay site uc college essay pre written essays for sale

phenergan 10mg tab

Kudos! Helpful stuff!

essays on the movie the help i need someone to write my essay me as a writer essay

Wonderful postings, Many thanks.

why i want to go to college essay cheap essay writing service us best website for essays

Thank you for sharing the info.

Very good info thanks so much!

Thanks a lot. Numerous content.

prescription drug cost [url=https://canadarx-drugservices.com]online pharmacy india[/url] best online pharmacy

Cheers, I value this!

canadian drugstore reviews canada pharmacy online canadian viagra

Very good info thanks so much!

Very good facts. Many thanks!

essay writing assignment write my essays write my report for me

You’ve made your position quite clearly..

help me write my college essay https://homeworkcourseworkhelps.com/ coursework writers

Kudos, I like this!

essays for college applications essays writing services cheap resume writing services

Thanks for sharing the information.

Seriously loads of valuable material!

canadian drug stores online prescription drugs canada canadian pharcharmy onlinecanadian online pharmacy

Great write ups. Appreciate it!

help with scholarship essays write my essay need a ghostwriter

Great knowledge. Thank you!

canada pharmacy online international drug mart canadian pharmacy online store pharmacy tech

I think this is a real great article.Really thank you! Fantastic.

I just saved your site.

Cheers, A good amount of posts.

mba essay writing service unique college essays best cv writing service in dubai

You stated this fantastically!

how to write a leadership essay essay writer jobs photo essay website

Wonderful knowledge. Appreciate it!

length of college essay essays writers web content writer

You actually reported that superbly!

canadian mail order pharmacies cvs online pharmacy best online canadian pharcharmy

Regards. Good stuff!

highest rated canadian pharmacies meds online canada meds

Appreciate it! Quite a lot of postings.

website to write essays https://writingthesistops.com/ writing help for college students

Really quite a lot of excellent advice.

best writing services reviews how to write a good college admissions essay websites to type essays

Very good information thanks so much!

Superb postings, Thanks.

good movies to write essays on https://writingthesistops.com/ help me write a speech

Wow, great blog post.Really looking forward to read more. Really Great.

Perfectly voiced certainly! .

drug stores near me canadian pharmacies top best canada pharmaceutical online ordering

You have made your point.

online canadian pharmacies online pharmacy canadapharmacy

Amazing posts. Many thanks.

writing an autobiographical essay writing prompts for essays website that write essays for you

Appreciate it, A lot of write ups.

essay to get into college essay writing services write my assignment ireland

Good posts. Thank you.

the best essay writing service https://freshapps.space/ help with academic writing

Terrific knowledge. Regards.

cialis online pharmacy prescription drugs online without northwest pharmaceuticals canada

You have made the point.

fda approved canadian online pharmacies canadian prescription drugs list of legitimate canadian pharmacies

Thank you for sharing the info.

Thanks, I enjoy this.

help me write a essay essays writing services company report writing

Terrific forum posts. Thank you.

essay help websites https://flowleadsua.com/ dissertation writer

Looking forward to reading more. Great blog article.Really looking forward to read more. Much obliged.

Kudos. Loads of write ups.

custom law essays essays writers thesis writer

Amazing all kinds of wonderful data.

online pharmacy no prescription needed pharmacy drug store drug stores near me

You are a great writer thanks.

Truly a lot of awesome tips.

canada prescription drugs discount pharmacy best online pharmacy stores

Nicely voiced of course. !

mba essay writing services https://essayssolution.com/ assignment writing help

Thanks a lot. Plenty of forum posts!

how to write a self assessment essay help write essay online essay website

Thanks for your hard work.

Point nicely applied!!

personal essay for college essay writing service best essay website

This is nicely expressed! .

essay on the help to write an essay cheapest article writing service

Position nicely regarded!!

cheap prescription drugs online canada meds canadian pharcharmy online

Kudos. Wonderful stuff.

prescription drug price comparison viagra online canadian pharmacy cialis from canada

Amazing tons of very good info!

how to write personal essays https://topswritingservices.com/ write my assignment ireland

Thank you for your hard work.

I am 43 year old female Thank you so much!

You revealed it exceptionally well.

persuasive essay writing essay typer article writing service review

You made your point!

tok essay help college personal statement essay professional personal statement writers

Many thanks! Good stuff.

canadian pharmacy without prescription online medicine tablets shopping prescription pricing

With thanks. Quite a lot of content!

what should a college essay be about https://agbsl.pro/ business writing service

Awesome facts, Many thanks!

online pharmacy usa canada pharmaceutical online ordering prescription drugs online without

Beneficial postings. Thanks.

where can i buy an essay online https://essaywriting4you.com/ write my thesis

Just wanted to say thanks!

You actually reported this fantastically!

essay writing service law school https://freshappshere.com/ online resume writing services

You said it adequately.!

how to write the essay https://englishessayhelp.com/ ghostwriting service

Regards, I like it!

canada pharmaceutical online ordering online pharmacies legitimate canadian pharmacy no prescription

Nicely put. Thanks a lot!

canada pharmaceuticals online rx price comparison online canadian pharcharmy

https://freenudez.com/x/freehookupsite/jerome-abg-ryder.html

Thanks for the blog.Much thanks again. Will read on…

Great, thanks for sharing this post.Really thank you! Really Great.

https://tinyurl.com/yyfzwznj

I loved your article post.Really looking forward to read more. Want more.

Thank you for your article.Thanks Again. Really Great.

Hey, thanks for the blog article.Thanks Again. Really Cool.

I am so grateful for your post. Cool.

https://freakycrush.com/milfsx/caroleelliott.html

serial

Appreciate you sharing, great blog.Really thank you! Will read on…

https://freenudez.com/x/hotnudes/berronelisa.html|

Im grateful for the article.Really looking forward to read more. Keep writing.

https://tinyurl.com/yxgdprfu|

https://tinyurl.com/yy2zt4ua

https://tinyurl.com/y2rfanpo

Really informative article.Really thank you!

https://freenudez.com/x/freehookupsite/jack-son-gan.html

https://tinyurl.com/yy5ktzba

https://freakycrush.com/freemilfvideo/falannie.html

I was extremely pleased to uncover this page. I need to to thank you for your time just for this fantastic read!! I definitely appreciated every little bit of it and I have you saved as a favorite to check out new stuff on your website.

Thanks again for the blog article. Really Great.

https://bangbuddy.org/l/snapsex/camaro8.html

Thank you ever so for you blog post.Much thanks again. Want more.

https://freenudez.com/z/nudes/ramonmonroy.html

I am so grateful for your blog.Really looking forward to read more. Fantastic.

You have made some good points there. I checked on the net to learn more about the issue and found most people will go along with your views on this web site.

https://tinyurl.com/y625q5rn

When I originally left a comment I seem to have clicked on the -Notify me when new comments are added- checkbox and from now on whenever a comment is added I receive 4 emails with the exact same comment. Is there an easy method you are able to remove me from that service? Cheers.

Really appreciate you sharing this blog article.Really looking forward to read more. Really Cool.

Muchos Gracias for your blog post.Much thanks again. Really Great.

https://tinyurl.com/yxj54uqa

Major thankies for the post.Thanks Again. Really Cool.

Thanks a lot for the article post.Really thank you! Cool.

Comments are closed.