How to Set Up an A-Frame

Leaning how to set up an A-Frame is a versatile tool used in rescue and material handling to manage loads safely and effectively. Setting it up requires careful planning and attention to detail. This guide will walk you through the process, focusing on precision, safety, and functionality.

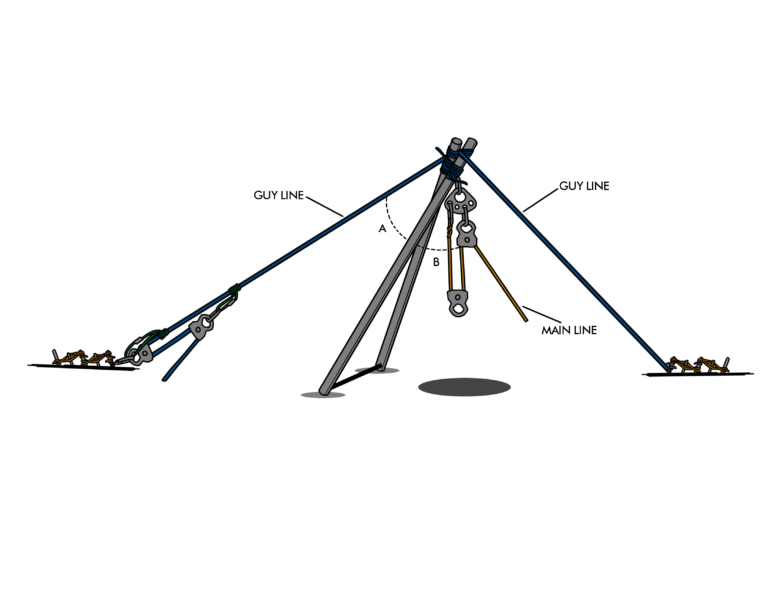

Positioning the A-Frame

The first step is to position the A-Frame correctly. Place the apex directly above the load area. This alignment ensures that the ropes and forces are balanced, reducing stress on the structure. Misalignment can lead to inefficiency or instability, so take the time to get this right.

Securing the Anchors

Next, secure the main anchor line at the apex of the A-Frame. This line carries the primary load, so it must be strong and securely attached. Depending on the operation, you may need additional anchors to distribute the weight evenly. These extra anchors add stability and safety to the system.

Installing the Pulleys

Pulleys are essential for guiding the ropes. Attach them at the apex, ensuring they are compatible with the ropes and rated for the expected forces. Proper pulleys reduce friction and make lifting or lowering the load easier and safer.

Adding Load Management Devices

Integrate load management devices like progress capture or descent control systems. These tools help manage the load effectively, whether you are raising or lowering. Choose the device based on the specific needs of your operation.

Performing Safety Checks

Before you begin, inspect all components. Check the anchors, pulleys, and ropes to ensure everything is secure and functioning correctly. Review the load paths to confirm the forces are aligned and directed properly.

Conducting a Dry Run

Test the setup by performing a dry run with a light load. This trial run helps identify any weaknesses or areas needing adjustment. Make necessary changes to the guy lines, anchor points, or rope angles to ensure stability and efficiency before proceeding with the actual load.

Improvised A-Frame Construction

If you need to construct an improvised A-Frame, start by selecting strong, straight poles. Materials like wood, bamboo, or metal work best, depending on what is available. Strip away any branches or protrusions to create smooth and uniform spars.

Lash the poles together tightly at one end to form the apex. The lashing must be secure but flexible enough to allow angle adjustments. Spread the free ends of the poles on the ground to create a stable base. Adjust the distance between the base ends to ensure proper height and balance.

For additional strength, attach cross braces between the poles. Secure the structure with guy lines anchored into the ground or another stable point. Test the A-Frame with a light load to check for stability. Make adjustments to the base, lashings, or guy lines as needed.

Key Points to Remember

- Position the apex directly above the load area.

- Use strong anchors and distribute the load evenly.

- Install compatible pulleys to reduce friction.

- Incorporate load management devices suited to the task.

- Perform safety checks and a dry run before starting.

- Test improvised A-Frames thoroughly before use.

Conclusion

Setting up an A-Frame requires precision and attention to detail. Whether using a pre-fabricated frame or constructing one in the field, the principles are the same: accurate positioning, secure anchors, and thorough safety checks. By following these steps, you can ensure a stable and efficient system for any rescue or material handling operation.

Peace on your days,

Lance