Class 5 Litter Handling

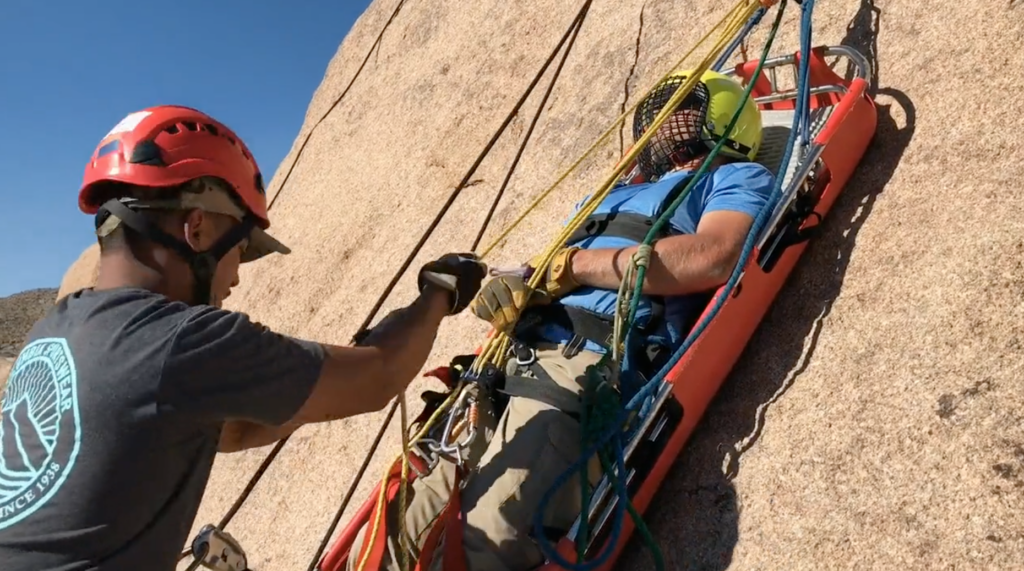

Class 5 litter handling represents the most technical and demanding aspects of rope rescue operations. This process involves safely managing the litter and patient in complex, high-angle environments, such as steep cliffs, overhangs, or confined vertical spaces. It demands precision in rigging, effective use of specialized tools, and seamless coordination among team members to ensure the safety of both the patient and rescuers.

Key Challenges in Class 5 Litter Handling

Class 5 operations are often complicated by the need to lower a litter and rescuer past obstructions like roofs, overhangs, or sharp ledges. In such cases, the litter tender plays a critical role in maintaining control of the litter while navigating around these obstacles. To ensure stability and efficiency, tenders may:

- Position their legs through or above the litter’s spider straps to hold the litter away from the wall.

- Let the litter swing gently under an overhang before repositioning themselves beneath it.

- Maintain a balance between control and flexibility to adapt to challenging terrain.

Techniques for Class 5 Litter Handling

Offsets

Offsets are used to move the litter and patient away from a rock face, wall, or obstacle when the handler lacks the ability to guide the litter manually. This technique involves:

- Minimal Movement: Offsets are used to clear specific obstacles or traverse short gaps rather than for prolonged horizontal movement.

- Deflection Lines: For larger gaps or more complex obstacles, deflection lines can redirect the litter’s movement safely away from hazards. Depending on the situation, one or two deflection lines may be required for added redundancy.

- Pendulum Risk Assessment: A second deflection or belay line may be necessary if there’s a significant risk of a pendulum effect causing harm to the patient or rescuers.

Guiding Lines

Guiding lines combine lowering systems and tension systems to “guide” the litter away from hazards and into a safe landing zone. Features include:

- Tension Control: A mechanical advantage system tensions the track line, ensuring precise litter positioning.

- Versatility: Suitable for both high-angle cliff operations and urban scenarios like high-rise building rescues.

- Coordination: Effective use of guiding lines requires constant communication between the litter tender, edge personnel, and the haul team.

Skate Blocks

A variation of guiding lines, skate blocks are often employed when operating on towers, high-rise structures, or cliff sides. These systems use tensioned lines to raise or lower the litter while maintaining a stable trajectory. Benefits include:

- Precision: Skate blocks are particularly effective when a specific landing zone is predetermined.

- Adaptability: This method can be used for both lowering and raising operations.

Two-Rope Offset System

When spanning larger gaps, a two-rope offset system may be employed as an alternative to deflection lines or Tyrolean traverses. This system incorporates:

- Dual Systems: Two TTRS (Two-Tensioned Rope Systems) or main/belay systems work together—one system lowers the load while the other raises it.

- Increased Capacity: This method is suitable for evacuating multiple individuals simultaneously, making it ideal for larger rescue operations.

Rigging the Litter for Class 5 Operations

Proper rigging ensures that the litter and patient remain secure throughout the operation.

- Mainline and Belay Line Setup:

- The mainline (typically blue) serves as the primary load-bearing line. It is tied to the litter using a long-tail bowline and connected to the steel anchor ring.

- The belay line (often yellow) acts as a backup, directly tied to the rescuer’s chest harness with a locking carabiner. The inclusion of a Purcell Prusik provides shock absorption in case of mainline failure.

- Etrier (Aider) Positioning:

- The etrier, or aider, provides foot loops for the litter tender. Pre-rigging the aider for vertical operations ensures that adjustments can be made quickly without compromising safety.

- Shortened Rigging:

- Keeping the litter rigging compact (4-5 feet between the steel ring and the litter) simplifies edge transitions and reduces the risk of snagging on obstacles.

Tendering the Litter

The litter tender is responsible for maintaining control and stability of the litter during Class 5 operations. Proper positioning and the use of tools like ascenders and AZTEK systems enhance their ability to perform this critical role.

- Using Ascenders:

- Ascenders, particularly those with spring-loaded cams, allow the tender to adjust their position on the tender line efficiently.

- Tenders can ascend by standing in the etrier and pulling the tender line through the ascender. To descend, the cam is opened to release tension, allowing for controlled movement.

- AZTEK Systems for Tending:

- The AZTEK LT (or “set of fours”) system provides the tender with precise rope adjustments, allowing them to raise or lower their position as needed.

- This system includes a progress-capture pulley and a lower Prusik hitch for added security.

- High-Tender Position:

- In overhanging scenarios, tenders should position their feet high, near the litter’s upper rail, to guide the litter effectively past the obstruction.

- Maintaining this position ensures that the litter remains clear of the rock face while allowing the tender to stabilize it using their feet.

Maintaining Safety and Efficiency

Class 5 operations require rigorous attention to safety protocols and operational efficiency:

- Securing the Litter:

- Before placing a patient in the litter, it must be secured to prevent accidental movement. This can be achieved by tying the mainline and belay line back to the anchor or using runners and straps.

- Managing Slack:

- Slack in the belay line should be kept to a minimum to avoid shock loading. Stopper knots can be used to limit the length of the belay line and prevent the tender from descending beyond the mainline.

- Anticipating Terrain Challenges:

- Tenders must remain vigilant, adjusting their position and grip to adapt to changing terrain or obstacles. In extreme cases, tenders may need to reposition themselves below the litter to clear hazards or protect the patient.

Key Takeaways

- Rigging Simplicity: Compact and efficient rigging reduces the risk of errors and streamlines transitions.

- Tender Positioning: Proper alignment and grip techniques allow the tender to maintain control and adapt to challenging terrain.

- Safety Measures: Use redundant systems like Purcell Prusiks and stopper knots to mitigate risks associated with anchor or equipment failure.

- Adaptability: Tools like the AZTEK LT system enhance the tender’s ability to adjust and stabilize the litter in dynamic environments.

Class 5 litter handling represents the pinnacle of rope rescue techniques, requiring precision, coordination, and the effective use of advanced equipment. By adhering to these principles, rescue teams can safely navigate the most challenging terrain, ensuring the well-being of both the patient and the rescuers.

Products Mentioned:

Peace on your Days

Lance