Types of Anchors in Rope Rescue

In rope rescue and rigging, anchors are the linchpin of every safe and effective system. They are the first link in the chain—and the one that everything else depends on.

Anchors are never one-size-fits-all. They must be selected based on environment, load requirements, and operational needs. From the rugged wilderness to concrete industrial sites, the right anchor defines whether a system succeeds or fails.

Below are the four primary categories of anchors used in rope rescue operations: natural anchors, structural anchors, vehicle anchors, and picket anchors. Each serves a distinct role—and understanding their capabilities is essential for modern rescue work.

Natural Anchors

Natural anchors are environmental features used for secure attachment in rope rescue and climbing. These include trees, boulders, rock formations, ice structures, or cracks in rock walls. They’re vital in wilderness or alpine operations where artificial anchors aren’t available.

Using natural anchors demands real environmental awareness. Rescuers must assess:

-

The anchor’s age and condition

-

Its load-bearing strength

-

The forces applied during rescue

Protection tools such as slings, webbing, or natural anchor rigging techniques allow teams to secure these features without damaging them.

Natural anchors reflect the intersection of raw nature and technical rigging. They remind us that adaptability is key—and that with the right assessment and equipment, the terrain can become your strongest ally.

Structural Anchors

Structural anchors are engineered attachment points built into man-made structures, including:

-

Buildings

-

Bridges

-

Towers

-

Industrial platforms

These anchors are designed to meet engineering and load standards. Commonly used in urban rescue, rope access, or confined space entry, structural anchors provide dependable, tested points for hauling, lowering, or securing systems.

They are typically:

-

Permanently installed

-

Load-rated and tested

-

Integrated into building or facility infrastructure

Structural anchors are the default in settings where the terrain offers no options—but human engineering steps in.

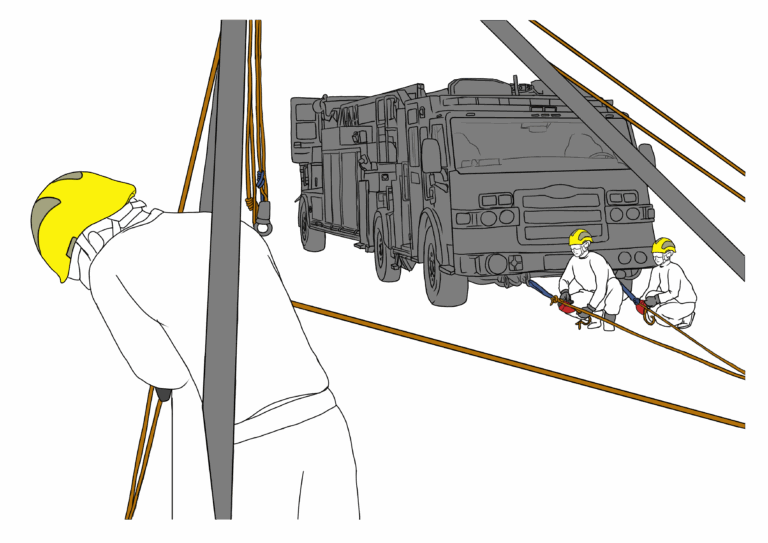

Vehicle Anchors

Vehicle anchors are used during rescues involving cars, trucks, or heavy machinery. These anchors play a critical role in roadside emergencies, industrial extrication, or remote access incidents.

They may include:

-

Anchor straps around structural vehicle parts

-

Integrated anchor points like frame loops or tow hooks

-

Winch lines and rigging adapters

-

Stabilization tools to prevent vehicle shift during rigging

Proper use requires understanding vehicle anatomy, load direction, and how to avoid compromising the structure during rescue. Vehicle anchors must be chosen carefully to prevent unintentional collapse or movement during hauling or stabilization.

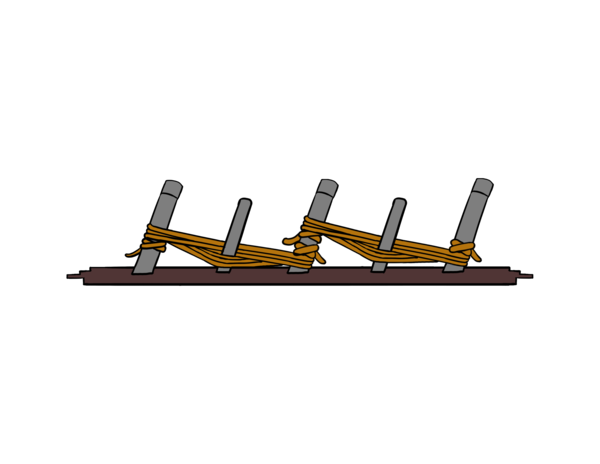

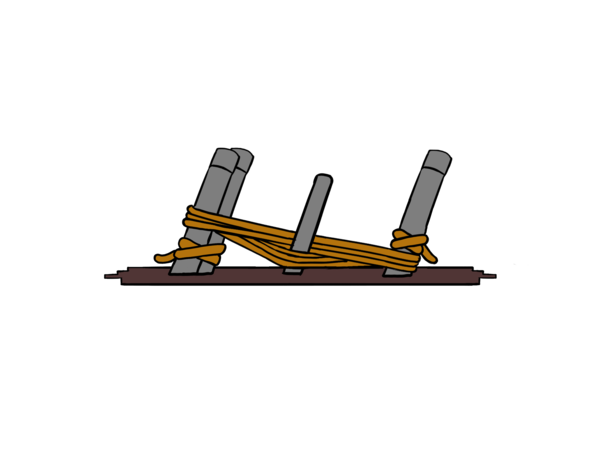

Picket Anchors

Picket anchors are metal stakes driven into the ground to create strong, earth-based anchors. They’re especially useful when no natural or structural anchors exist—such as remote wilderness areas or open ground scenarios.

A single picket can be used, but multi-picket configurations dramatically increase holding strength.

Standard Placement Guidelines:

-

Pickets driven at a 15° angle, with ~60% buried

-

Spacing: ~4 feet apart (or equal to picket length)

-

Soil must be tested or evaluated for consistency (clay, sandy loam, mixed, etc.)

Common Strength Estimates (based on configuration and good soil):

-

1-1-1 (single picket): ~1,800 lbf

-

2-1 (two pickets + lashing): ~2,000 lbf

-

3-2-1 (full configuration): ~4,000 lbf

In California State Fire Training tests, a 3-picket in-line system in compact soil achieved 5,000 lbf (22.2 kN). Multiply estimated strength by 0.9 or 0.5 depending on soil quality for conservative load estimates.

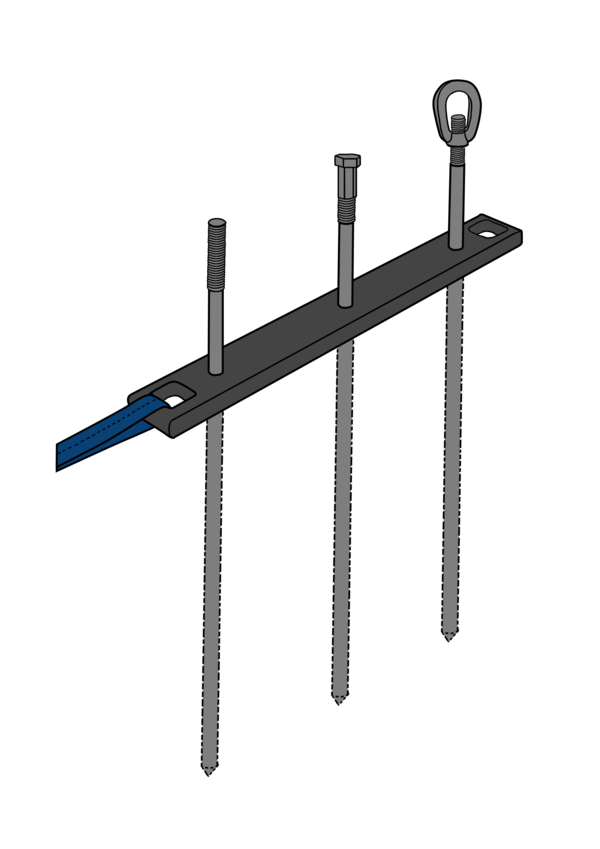

The Hurley Picket Anchor System

The Hurley system improves on traditional picket setups by using a prefabricated anchor plate that connects the pickets. This:

-

Distributes load evenly across all pickets

-

Eliminates need for a Spanish Windlass

-

Speeds up setup time

-

Improves pull-out resistance

-

Allows two systems to be linked end-to-end for added strength

Each picket is driven vertically into preconfigured holes, simplifying spacing and force alignment. This design saves time, increases reliability, and reduces potential setup error—especially in high-stress situations.

Final Thought

Whether you’re on a cliff face, an urban rooftop, or a remote dirt road, anchors define your system’s limits. Choosing the right one—natural, structural, vehicle-based, or ground-driven—can mean the difference between success and failure.

Understanding the environment, knowing your equipment, and planning for forces under load are what elevate a technician into a trusted rescuer.