For years, the arborist’s preferred method for accessing a tree was a climbing hitch in a doubled rope system. As we’ve discussed, this method works beautifully because the rope sees half the weight of the climber on the anchor side and half on the hitch side. This perfect balance allows the hitch to advance and descend under full control. However, the hitch binds down and becomes uncontrollable when applied to a single line with 100% of the climber’s weight. This fundamental problem with physics led to a pivotal moment in climbing history. The solution was the Rope Wrench Revolution From Double Ropes to a Single Line, a story of innovation, trial and error, and a final, groundbreaking breakthrough.

In 2008, what seemed like a gloomy day for arboriculture suddenly saw the clouds break and the sun shine down. This was a day that saw the revolution we needed to work with a hitch on a single line. A gentleman named Kevin Bingham made a very, very important discovery. He took a piece of gear and modified it to do something it was never meant to do, a common trait among many clever arborists.

The Weight Problem Why the Doubled Rope System Ruled

The entire foundation of the doubled rope system is rooted in a simple principle of physics. When a climber’s rope goes over a branch and returns to the ground, it creates a large, running loop. The climber’s weight is distributed evenly between the anchor side and the hitch side. As a result, the anchor sees roughly the climber’s full weight, but the hitch only sees half or slightly less. This allows the hitch to function smoothly and predictably. It holds firm under half the weight and releases easily for descent.

This setup works perfectly for controlled descents or for walking out on a limb. However, it’s a non-starter for a static single-line system. When a climber attaches their hitch to a single, static line and puts their full weight on it, the hitch sees 100% of that weight. It immediately binds down, becoming impossible to control smoothly. This problem forced arborists to rely on the less efficient, friction-heavy doubled rope system.

Kevin Bingham’s First Breakthrough

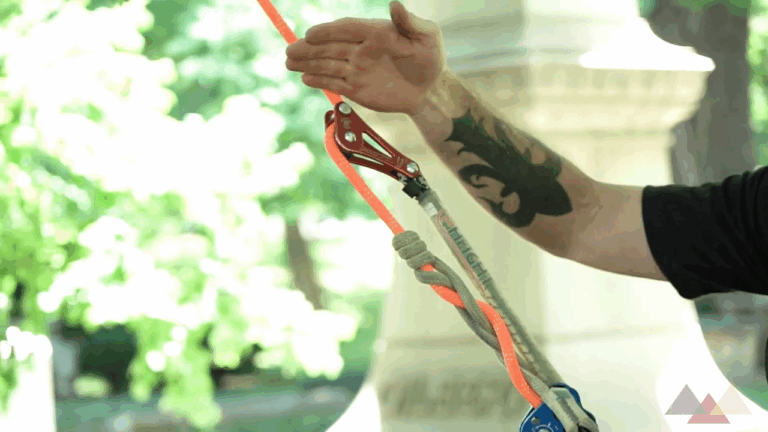

Kevin Bingham noticed this problem and began experimenting. Using a figure eight knot and a pulley-carabiner, he took a small bite of rope above his hitch. He connected his carabiner to this bite and anchored the bottom part back down to his harness. What he discovered was that this simple configuration created a small, contained loop on a single line. This loop beautifully mimicked what was going on in the large loop of a doubled rope system. When he put his weight back on the system, the bite of rope took a significant amount of the weight off the hitch, allowing it to become far more controllable.

This was a major step forward. The rope itself was now static, eliminating the constant friction of a running rope. It worked very well for descending and for limb walks. It was not, however, the “holy grail.” The one problem with this setup was that it could not ascend on a weighted system. To ascend, a climber would have to unclip the bite from the top, ascend in another manner, and then re-establish the system. This made it a very big step forward, but not a truly efficient system for all of arboriculture’s needs.

The Holy Grail The Rope Wrench and Neutral Ascent

Thankfully, the very same person who started this revolution would take it to the next level. Kevin Bingham’s journey from a modified figure eight led him to another experiment using a simple box wrench. He installed the box wrench on the line and anchored it down to a carabiner. He noticed that with this setup, the device could get into a “neutral” position. This allowed it to ascend and descend on a single line. It was a groundbreaking discovery, but as you might imagine, the box wrench shredded the rope and was incredibly unsafe.

This dangerous experiment simply proved the mechanics. Bingham then worked to create a purpose-built, midline-attachable device that would create that perfect bend above the hitch without destroying the rope. This device, which became the Rope Wrench, was a contained doubled rope system set up on a single line. With the climber’s weight on it, the bend in the rope would take the pressure off the hitch, allowing the hitch to work very smoothly. But the biggest benefit was that the device could get neutral, meaning it could ascend. This truly was the holy grail for arborists.

A Safer Evolution The Stiff Tether

Even with the Rope Wrench, there was still a potential downside. The “neutral” position, which made ascent possible, was also a minor risk. With a loose and sloppy tether, the device could come down and accidentally disengage the hitch, a very unsafe scenario. The solution was a final refinement.

The Rope Wrench setup was cleaned up even further. A smaller, lighter version of the device was created to be used with a stiff tether. This stiff tether pushes the device away from the hitch when it gets neutral, virtually eliminating the possibility of it coming into contact with the hitch and disengaging it. This final setup has proven to be the absolute holy grail for tree climbers. With a static single rope, it eliminates the extra friction of a running rope. It keeps the hitch consistent, no matter what happens in the tree. Unlike a doubled rope system, where rope drag changes the hitch’s characteristics, the Rope Wrench regulates the hitch perfectly the entire time.

The Rope Wrench Revolution allowed arborists to ascend, descend, and work position in a tree on a single, static line. This innovation not only made the job smoother and more efficient, but it also made it safer by ensuring a consistent, reliable hitch in all situations.

Peace on your Days

Lance