The Omni Of The Rope Rescue and Rigging Pulley World: Rock Exotica Omni-Block Swivel Pulleys

So what exactly does "Omni" mean?

The designers of the Omni Block pulley have some very elevated claims about their product. Here are a few definitions of the word “omni”.

- Combining Form

- Without Limits

- In All Ways and Places

- Universally

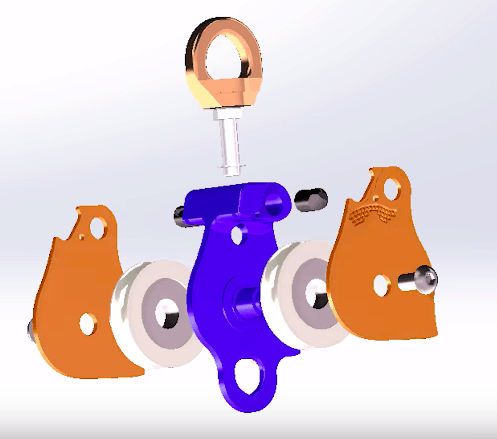

The Omni-Block combines a swivel and pulley into one tool, and incorporates a unique sideplate that opens while the pulley is still attached to the anchor. The insertion of this product by Rock Exotica presumes that it is the end-all and be-all of rescue pulleys. Could this really be true?

- Swivel

- Pulley

- Moving Sideplates

Generally, rescue pulleys are built for building a raising system within a given rope rescue operation… but not always. Other options could be for redirects or anchoring. Anchoring? Also most pulleys worth a hill-of-beans, need to meet a 90-95% efficiency rating. So take a quick look at this video… would you say that these pulleys come close to Rock Exotica’s claim?

Traditionally, a pulley is connected to a swivel by a carabiner. However, the Omni eliminates the need for the carabiner, reducing length and pieces of equipment in the rigging system. The short length of the Omni is important when used in high-angle, confined space or other space-sensitive rigging environments. The reduced weight of the Omni will make hauling your gear easier. Additionally the Omni sideplate can be opened without detaching from the carabiner. Traditional pulleys require removing from the carabiner to change the rope. With the Omni, the user is able to do this while the pulley is still secured.

-

- Install and remove rope while still connected to the anchor

- Sideplate locks with two-stage, double-catch safety mechanism

- Integrated swivel allows pulley to orient while reducing gain

- Connect, install and remove rope with one hand

- CNC machined for optimal weight & strength

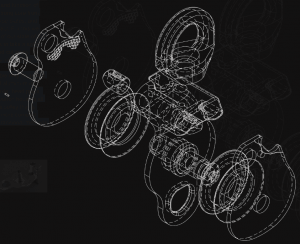

How The Rock Exotica Omni-Pulleys Are Made

How The Rock Exotica Omni-Pulleys Are Made

- The Omni Swivel Pulley is made the same unique way that many of Rock Exotica products are made—from solid material. The design and function of the pulley require a strong core from which the sheaves, side plates, and swivel top must connect. For this we rely on the capability of our state of the art machining centers to take a solid block of aluminum and cut away material to create this integral part.

- With precision available only on such a machine, the block of aluminum is transformed into an axle, head piece, becket, and release button housing all in one. The result is a pulley that is lighter, stronger, and more compact than those made by traditional methods and stamped parts.

Most People Never Read This Stuff

- Strength: In a single pulley, half the load is on one side of the rope and half is on the other. The total load on the pulley is thus 2x the mass that is being raised or lowered. In a double pulley the total load is 4x the load on the 4 individual ropes. This is illustrated on the pulley. Breaking Strength & Working Load are based on this equal loading. If the sideplate is not fully locked by the button, the strength will be severely reduced, to about 10kN, but also, the rope may fall out. Pulleys must be free to align with the load, any restraint is dangerous.

- Working Load Limit: Is based on about a 4:1 safety factor. You must decide if that is sufficient in your situation or if you need to adjust the WLL.

- Prusik Use – Caution! Prusiks must always have an experienced person tending them. Never allow a jammed Prusik to be pulled in between the sideplates. This can bend or break the pulley and allow the rope to fall out! Breakage Hazard Do not let an object in between the sideplates and never rig your system so that the pulley is forced against something that could break or open the sideplate, allowing the rope to fall out.

- To Open Sideplate Depress the button & rotate sideplate counterclockwise (clockwise for the back side of the double). It should stop at the 2nd button detent. In this position the strength is severely reduced, but the rope will not fall out as easily as it can in the fully open position. To fully open, just depress the button again & rotate.

- To Close Sideplate Rotate sideplate past the 2nd detent to the fully closed position. Verify the button extends fully through the hole & test that the sideplate is really locked & secure. You should be able to close it one-handed, but the components will last longer if you depress the button a little to help it when closing.

- In Use Do not allow anything to press button & accidentally unlock sideplate. Do not allow anything to pry the sideplates apart, or opening or breakage my occur.

- Pinching Hazard Rope travelling through a pulley can suck in hair, fingers, clothing, etc., causing injury & jamming the pulley. Guard against this. Inspect Before & After Use Check all parts for cracks, deformation, corrosion, wear, etc. Verify that the swivel top rotates normally & the axle screw has not loosened. Verify smooth rotation of the sheaves & security of the axle screw. Verify that the sideplate rotates normally & the button operates properly. The button must not be impaired by dirt, ice, corrosion, etc. Verify smooth rotation of the sheave.

- Inspection During Use Regularly inspect and monitor your system, confirming proper connections, position, fully locked sideplates & fully extended buttons.

- Intended Use This Personal Protective Equipment (PPE) should only be used with energy absorbing systems such as dynamic ropes, energy absorbers, etc. & slack must be kept out of the system to prevent high impact falls. It is intended for use by medically fit, specifically trained and experienced users. Thorough and specific training is absolutely essential before use. Being at height is dangerous and it is up to you to reduce the risks as much as possible – but the risks can never be eliminated. There are many ways to misuse this equipment, too many to list or imagine. You must personally understand and assume all risks and responsibilities of using this equipment. If you cannot or do not want to do this, do not use this equipment.

- Environmental Factors Moisture, ice, salt, sand, snow, chemicals and other factors can prevent proper operation or can greatly accelerate wear.

- Compatibility Verify compatibility with other components of your system. EN12275, EN362 EN354, EN565, EN566, EN1891. Incompatible connections can cause detachment, breakage, etc.

- Lifetime Unlimited for metal products, but will often be much less depending on conditions and frequency of use; it could even be a single use in some cases.

- Retire from Service & Destroy if it: 1. Is significantly loaded. 2. Does not pass inspection or there is any doubt about its safety. 3. Is misused, altered, damaged, exposed to harmful chemicals, etc. 4. Button fails to extend fully. Consult the manufacturer if you have any doubts or concerns.

- Maintenance & Storage Clean if necessary with fresh water, then allow to dry completely. The button may be cleaned by holding it upside down & spraying a light lubricant into it while operating it. Store in a dry place away from extremes of heat and cold and avoid chemical exposure. Principal Material Aluminum alloy, anodized. Repairs or Modifications to Equipment Are only allowed by the manufacturer or those authorized in writing by the manufacturer. Detailed Inspection In addition to inspection before, during and after each use, a detailed inspection by a competent inspector must be done at least every 12 months or more frequently depending on amount and type of use.

[thrive_lead_lock id=’51985′]Hidden Content[/thrive_lead_lock]

Peace on your Days…

Lance

9 thoughts on “The Omni Of The Rope Rescue and Rigging Pulley World: Rock Exotica Omni-Block Swivel Pulleys”

874439 38871Right after study a couple of with the content in your site now, we genuinely such as your technique of blogging. I bookmarked it to my bookmark internet site list and will also be checking back soon. Pls take a look at my web-site likewise and make me aware what you believe. 612363

Hello there! I know this is kinda off topic however , I’d figured I’d ask.

Would you be interested in trading links or maybe guest

authoring a blog article or vice-versa? My site covers a lot of the same topics as yours and I

think we could greatly benefit from each other. If you’re interested feel free

to send me an e-mail. I look forward to hearing from you!

Superb blog by the way!

Bedeva erotik sex filmleri. beles erotik film indir.

Oyuncular Nathaly Cherie, Max Dior, Karol Lilien, Violette Pure, Nick Vargas.

Yönetmen Roma Amor. Tür +18 Filmler, Erotik Filmler,

Yabancı Erotik Filmler. Etiket +18 film izle, Günahkar Kadınlar +18 filmi izle, Günahkar Kadınlar erotik filmi

izle, Günahkar Kadınlar sex filmi izle.

Genç kız günah çıkarmaya gittiği kilisede papaz günahlarından arınması için bu kıza yarağını

uzatarak ağzına almasını ister. Bu kız önce şaşırdıktan sonra ağzına alır ve papazla deliler gibi

sikişmeye başlar. Esmer Porno, Konulu Porno, Youjizz Porno Özlem Acar.

Nice article. I hope your blog guide would be helpful for me. It’s great to know about many things from your website blog.

I had to write you the little bit of phrase for you to thanks a lot once more approximately the first-rate pointers you’ve contributed in this site.

One of the important part of keeping your home clean is Air duct cleaning. lot of people try to clean their air ducts by themselves , but somehow they cant’t do it properly. But san antonio air duct cleaning avis air duct cleaning can assure the guarantee of quality.

Affiliate Software for Small Business is highly useful for businesses to use to grow themselves. Businesses can use this software, and promote them on their channels.

With the promotion of this software, businesses can earn huge commissions and push themselves forward.

I examine this paragraph absolutely on the subject of the distinction between most up-to-date and previous technology, it’s a first-rate article.

Comments are closed.