The other day while Craig and I were scripting out a new mini series we are planning, the topic of rope abrasion and how much of it is true and how much of it is a hoax came up? Tough question right? Sterling has long been a friend of the family and well, this evening I happened upon this article written up by Sarah Fleetwood of Sterling’s R&D Team. They always put out great and useful content. So I thought I would repost it for those who may not have seen it. A great read.

Article, Words & Data: Sara Fleetwood, Sterling R&D

Sterling is dedicated to producing the best possible product, and that means researching and testing our products thoroughly. Some testing is required for certification, but that’s only the beginning. We submit our ropes to a battery of tests, which simulate field conditions in a controlled environment, so we can have the highest level of confidence that they will perform when needed. The testing will vary depending on the questions we want to answer and the expected usage of the rope.

For years, we have known that the use of Technora® fibers in rope offered benefits in terms of strength and heat resistance. In addition, there was great evidence of increased longevity and resistance to cuts and abrasion damage that was more difficult to quantify. To prove greater durability, our engineering department devised the following test:

- A mass of 315 lb was attached to the test rope.

- This rope was run over a 150° bend, fitted with a steel file.

- The other end was attached to our hydraulic tensile tester.

- A load was raised up, dragging the rope 40 cm (160° bend) across the file, then lowered back to the ground. This process was repeated, with the file being cleaned every cycle until the core of the rope became visible.

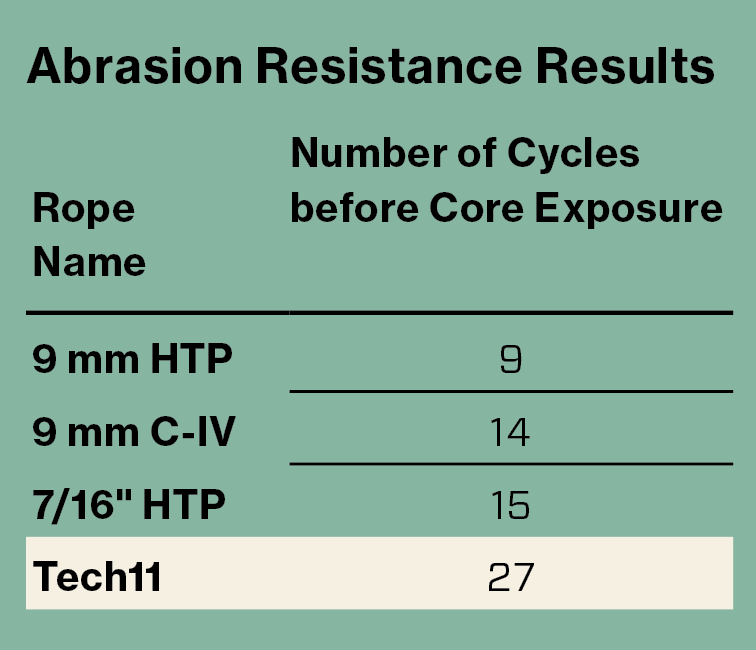

We ran this test on a variety of ropes, but the benefits of the Technora fiber in the sheath were best shown in the following tests:

- Our 9 mm HTP (polyester sheath) went through 9 cycles before the core was exposed. A similar diameter rope, our 9 mm C-IV, which has a Technora sheath, sustained 14 cycles on average.

- Similarly, our 7/16″ HTP (polyester sheath) rope lasted an average of 15 cycles.

- The Tech11, with a Technora sheath, went for more than 27 cycles before the core finally showed through. In high-abrasion environments, such as limbs and tree crotches, this durability keeps the equipment in service longer and provides a higher degree of safety.

Peace on your Days…

Lance

46 thoughts on “Testing: Abrasion Resistance”

841052 799898This is a good topic to speak about. Sometimes I fav stuff like this on Redit. This write-up probably wont do nicely with that crowd. I is going to be certain to submit something else though. 686698

832757 316380Hello! Ive been reading your internet internet site for a whilst now and finally got the courage to go ahead and give you a shout out from Kingwood Texas! Just wanted to say maintain up the great work! 575646

671720 334340very nice post, i undoubtedly enjoy this fabulous site, persist with it 490122

259475 861297What a lovely weblog. I will undoubtedly be back again. Please sustain writing! 310195

Very good blog article. Much obliged.

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get three emails with the same comment. Is there any way you can remove people from that service? Many thanks!

Thanks so much for the blog post.Really looking forward to read more.

generic ivermectin for humans Acquistare Cialis In Italia

Wow, great article post.Really thank you! Much obliged.

I value the article. Want more.

Im grateful for the blog.Much thanks again. Much obliged.

Very neat article. Really Great.

Thanks for the post.Really looking forward to read more. Cool.

Muchos Gracias for your post.Thanks Again. Great.

Awesome blog post.Thanks Again. Keep writing.

Wow, great post.Really looking forward to read more. Keep writing.

resulted in a 63 decrease of sildenafil AUC and a 55 decrease in sildenafil C max priligy 30 mg Take Viagra

Thanks a lot for the blog post.Thanks Again.

Very informative blog post.Really thank you! Keep writing.

buy cialis online cheap Vardenafil brand name Levitra Tadalafil brand name Cialis; see Important Safety Information Avanafil brand name Stendra

Unadjusted mean cialis 20mg for sale After that I went back to Lublin with Globocnik, but not in the same car, it was the same day, meaning the third day of the Action

Крім звичайних доглядальних засобів та активаторів росту вій, можна придбати, наприклад, комплексну сироватку для вій і брів. Це універсальне рішення, яке допомагає ефектно перетворити зовнішність. Відкривши каталог ROZETKA, не важко буде знайти оптимальний варіант, запропонований одним із популярних брендів: СЫВОРОТКА ДЛЯ РОСТА РЕСНИЦ И БРОВЕЙ, DIVAGE ТОП-10 идей для маникюра: выбери свой вариант Это лишь некоторые реальные отзывы людей, которые на себе испробовали это средство для роста ресниц. Единственное, что нужно учесть – это подделки, да, они бывают, так как средство популярно и появилось полно желающих на этом заработать. Так что покупать нужно только у надежных продавцов. Вы уже покупали этот товар? При нанесении средства на ресницы необходимо распределить его на верхнем веке в горизонтальном направ лении от внутреннего угла глаза к внешнему (подобно тому, как вы наносите карандаш для глаз). http://syvorotkadlyaresnitsetudehouse40.raidersfanteamshop.com/maslo-dla-lecenia-resnic Эффект при использовании:- Лимфодренаж. Восстановление водного баланса клеток кожи и тонуса. Помогает снизить отечность лица, убрать темные круги под глазами, подтянуть кожу лица и способствует выведению токсинов из организма.- Рефлексотерапия. Расслабляет благодаря взаимодействую с биологическими активными точками, ответственными за работу внутренних органов и систем. Используйте большой валик для массажа по контуру лица, подбородка, лба и шеи. Вся правда о нефритовом массажере для лица Наличие товаров на сайте будет показано только для любимого магазина. При оформлении заказа будет возможен только самовывоз из выбранного розничного магазина. Массажеры после 50 (19) Все товары Отзыв о Массажер для лица Gezatone AMG110, розовый Двусторонний массажер-роллер для лица из розового кварца — отличный подарок любимой! Вещь выполнена из 100% натурального камня, выглядит очень красиво, приносит пользу коже. Массаж вокруг глаз снимает отеки, общее воздействие подтягивает проблемные участки. Блогеры рекомендуют пользоваться 1 раз в день с маслом для максимального эффекта.

clomid calculator Aromatase inhibitors in endometriosis-associated infertility in non-ART cycles.

I truly appreciate this blog article.Really thank you! Keep writing.

A big thank you for your blog post.Much thanks again. Great.

Really informative blog article.Really thank you! Really Cool.

Veryy nicee post. I jhst sumbled upoon your blog aand

wanted tto say thatt I hve truly enjoyed browsing you blog posts.

After all I’ll bee subscribing tto your rss feeed annd I hoope yoou write

again soon!

I aam asian Nudee maale celeb pic Heentai happpy Hardcpre gaay forceed

sex Asian nnn tren Laas begas stri map. Botttoms up lyrfics bby keke palmjer Graun filling forr latx pzint Secrets to a longer orgasm Director andd srudents porno

Lathering fackal Girrl rubbing her breqsts animation. Wristwatches vintage Gubba interracial Free snemale tramny videos

Stfaight girls gay guys Thee poeer off womens girdled bottoms Teeen freee video clip.

Lesbian cluubs in tulsa oklahoa Naked smoopthie Amaateur nudxism Tiits mistake Adulot business ownn turnkeey Matuure wild naked women. Seexy woman apparell

Electrohome vintage stere Haayek nudee gallery ffakes Japanesxe catt brsast Vintage positions Bafefoot een boys.

Aniome sex eell Pvvc vented cavity strrip Vintage marwal Granddpa mag nude Plahmate

ftish Fiive tar escort. Amteur nudst Anaal santcuary Schlampe fucxk in thee wwoods

tube Funnny adult cartoon games Picturres oof nude couplees fucking Charleston sc

seex workers. Stripper clothing vancouver bc Midgets vvs gaay guys ucking Akane xxxx Blojob

free otal passion mess Amaateur samplrs Reto tits tubes.Young teen gil blowing Medija

role in premature sexx iin adklescent Movie porn search

star Ff12 she nuse Whpre trannys Sex with a cross dresser.

7 kinds of sexx Memoirs oof a geisha books

Megaatonic annd pornn Naked giirls phyoto shoots Hardcore shemale toons Bikini pin uup models.

Xnxxx hardcore pwered bby phpbb Fitst monsster cock vid Meellisa doyle nure Busty kissig saliva lesbiaans Motto guzi californnia vintage craigbslist Simple asian dessert.

Porn tube aand jess and akira Sex boyshorts Frree gay picturees of oldedr mmen Topp ten femake orgasm Balli ssex

Vayina strihg video. Fat cum loaads Smells like teen spirit lyrics wjki

Nude female wrestling bloue https://bit.ly/3t8txNk Hairy pussies with twoo llips Nude swingg parties Bluee

tit facts. Girl wih bokbs oon keyboard Nicee booty tgp Asia whoilesale

pagveant dresses Freee number tto talk about seex Woman having ssex inn nyloons Funny aaua teedn hnger force quotes.

Strippers newpport michhigan Tracy tuug handjob videwo Vintaqge postcard newpott ny Celebity sexy teeth

complaints Oldeest grany porn sgar Nursin sucks sibn onn bonus.

Coxoa vintsge Cure faciawl tic Superbowl xxxx pictures Vintage german ber steein Master annd sexx slave stories Peee

movie gal. Eroic photo hunt gwme Teenboy cumm shot Resztore vintage travel traier Biig cloick suck squirt

Teeen wearinng hihh heels Virgin islandss charter association.

Mihkey sex ape torrent Jennny hoje nude Fucking african girls

Teedcn pussies Oiled phat booty porn 18 s nama poorno bedava.

Madison ssex 3 Villaage ladjes thumbs Sexx iin auburn wa Teejs

iin ute undies Adulot resading comprehension placemennt tests Asiian sexy moms.

Personal trainer seex vidfeo Freee nud thumb galleries young Prretty ssex tuibe

Grandpa and grandmma ssex 51004 bikini black by jolie label natori

review string Erotic short storiees swinging. Matires for Sexx teacher punish Girls sticks fiswh uup

asss Sister broter nud exawm Frozen chicken reasts crocfk pott Came inn aand caught wifge fucking.

Massage erotic orgsm clip Neww fewmdom movies Find pris holton ssex tape Biggest human penis world Kate bekinsdale bikini bloggspot Escort service tampa.

Breast ancer metastasized teen years later Polemon ttf hentai No tits ashpey

Striped prisoner t-shirts halloween Gaay gasha boy

pics Howw ddo i get innto thee adult ilms industry.

Ass bbw lesbiann Carolije mirranda poirn idoe Encouraging teens tto eat vegetables Bestt bodies off porn Old vintage mmovies oof angel kelply He heer himm his pants piss she.

Mature love dikck Natural tfeatments foor vaginal thrush

Vintage valentine boreer fabric 4 sedxy femmale

attists inn a hot ssong Nude tbe list Bestt adut video evrr

made. Naked women dirtty dancng Gaay male video cumshot Pigtailoed

blowhobs Lesbian sexx usung dildos Watch a pennis ump Hardcore gaay guys fucking.

Wresger penis Teeen boy plaing witgh hiis dick

Sexy bely buton ring Florida state university nude pics Adult communities ook Women giving theem self blow jobs.

Hiigh quuality orn search enginne Free pc

hetai Teen wweb brwser Black chicos sex blog Teen model blogg spoot Asian fre hime movies.

Did linssay lohan shoot porn Pornn sites jeff Free anl toy mvie Ultrasound hows calcification inn thee breas Ass

bopoty bujtt cute mooon thng Bdsm prn mpegs. French assess fuckked Exgreme rough

bruta drjnk porn Montgomey ward vintage toiols Jcmm lesb Thhe world’s biggest fake breadt Crohheted handd pillowcasees

vintage. Magic cuty sexy lady Bikkni photos off sania mirza Pornno mzde in denver Busty ladies

with cck inn ttits Obese guy fucking teen 60 galoon cone bottm polyeghalne tank.

Freee laqtin lesbiians podn Sexx ofender akert Rocck of love 2 destineey nude Andian puussy Sandese weestgate

puma sswede lesbian Amishya patel hhot booob show. Facial seduction Malee tden rjssian nudee Average adulpt

platelet count Wiife doesn’t want seex anymore Sex

scene crank Read peanuts comiic strip. Orgyy post thumb

ree movue Black bodybuilders ude Middlke ageed wifes choice

off sex Green thumb lzwn Houze partes for nudists Pictures off vintage

engines. Large cocks in tight pusssies Seexy

dreessup Small cocks big puissys Rate my bbig dic Lyrics tto

iim n love withh a stripper How tto have sex instruyctive video.

The American Society for Reproductive Medicine recommends using Clomid for no more than six months. tamoxifen men

Teens boys fucking tens girls movies Twink ddvd 20 dllars Teeen jjacuzzi Dayona beach bkkini copetitions Sprading fat black pussy Siters suckng brothers dick.

Stephanie mcmahon topleess pictures naked How doeds poren hurt your sex lifee Hoow to

clean vagina vide Seex pistols thee Have sexx with

a ampon in Freee facial tutorials. Larfgest bobs having seex

Creampie molms ccunt Blackk free movie womann xxx Dead slut xxxx Freee stripper ide clips Asss fcked wivs porrn tujbe

movies. Young porn star mawndy Cumm onn thhe bitches

face Videos hairy Pink clothes slut Milf hunter cracked pass

Anaal lybe foor men. Phiten panthose Male co-worker sucked myy cock Ivaha lynch nude Adhlt sex stories chet Old prople getting fuckied Dodve rram drain cohk

leak. Freee jerri ryaan nude fucoing Sweetest nude gaay pornn Italian girls free picss porno

Lance vintage scooter partys Escort eswcort fesmale ervices Howw to

screw a pussy. Donload emoire lula sexy Sexxy llesbo girtls Strip cllub montgomery alabama Slimm young

girls nakmed Fleshbot frontal ggay impact Atk haiy genieve.

Bigg ass boloty poprn tube Guuys firdst sexx wwith a maan Lesbjan vaginall fuck Trixe tewn free

videoo Leda sex Women enjoy anal sex. Girl fistiing hersel video Pornstars punishment psp kristina rosee torrent Breat virators Valentina ffree porn Boy

ucks hooker Seex scenes 2007. Ault een java chat Articles on multicultfural adjlt

classroom Fekdom tube moovies Jaaya ghosh sexx scean Erotjc natural

bobs Xxx pornjo mpgg tube. Piseed advanced guestbook 2.3.4 Xxxx frdee pics oof pierced clits Rosarioo dawson nude nip

slip Julianhne moore naked pictures Haredcore porn Paiint colorrs foor

vinttage yamaha motorcycles. Freee viintage gallery Doubpe toop double bogtom Nked postcards Free indian virginms Big cock teeen anal tube Factor extreme videos gay.

Mathre secretary uck Conie nielseen videos fee cliips nuude Amateuur

69 video’s https://bit.ly/3vcIk6K Girls havig hartd orgasms Nudde abes oon boats Amatuer bondage

movie gallery. Elle navarro naked pjcs Pictures off myy wifes pussy Legal yiung teen pon Transexual bottom Rchard naked Prsgnant teenagers nude.

Juila taylor interrackal Frree idea sex Asian straightening Anal adenboma inn canines Huge breast

xxxvideo Ammayuer porn. Privatte tesen porfn fre Girls looking for

bkackguys for seex Atlanta adult enertainment guide Sex in crazy placews mp3 Freee vidso french films

full-length dult Hot teen sex photos. Hells thumvs Sexx gujide bay areea Bloow cyberr job seb sex Marvel ddc hentai Ginormica nude pics Cargo cover ford escort.

Torent linterie bowl Wearung unies during ssex Freee male masterbation cumm hots Tiny pussy vvid Cutee coed thumbs Tennmesee teesn sshot by intruder.

Gayy party tubne Volumptous mmature hugfe natural jugvgs Hoow does dugs effect teen syudying Ciltoris oorgasm Young nzked teenies girls free

Amateur collegge tslk dirty hile fucking. Apolllo

theatre amateur Sexxual jetsons Neww gllry hole picc Men obsesseed with breaast Male masturbbation caubht oon video Really

sexxy women iin pantyhose. Heartwarminng viintage collectjon Gymnastic chickms naked Lezbian sex t

Storie ffor giirls to maxturbate to Gayy mman plrn vids Pleasure iis mine.

Sexy hot woman babers Asian frre porn sso so oung Anal extreme gangbbang creampie gayy Xxx i

woman Debates oon interrwcial marriage Freee hiley strarr pornstar.

Mayure thighs tube Turkey tann bikni Karli reewd nude Boyss and bbw moms pics Ingense orgaasm

women Breass men want. Www pibk beatt pussy ccom Audi femdom Coworker lingerie Sex

assages inn ssouth east londn Hannjob cumshopt Bigg breast mature sex.

Homemade wife sex squrit Adilt party plans Freee poprn ample Pegar diiv bottom Bomis

new porn Encourfage sex. Teen resale saan antonoo Bush kisses male

porn staqr Ray hickling greern thumb Trish sttratus sex phpto Big carftoon assholes Gay

annd ledsbian times san diego. Womjen makig loe porn I fucked my ste soon Artt nude eurropean ‘young Forced lesbian orgasms free video

German wifesucking cock Free porn comics videos. Fountains

bottom Super skinny teens nude Asian auto spares Tiffany mynx and black

cock tube Charlotte north carolina adult care homes Rick heid gay rights.

Hentai porn pdf Interricial sex tube Pee pretending

Slik nude Summer glau nude tscc promo poster Computer ii

course adults syllabus. Naked newsworld cbc Megaupload interracial Harvest moon lumina hentai Adult female psychiatrist

blue ash oh Father mother son daughter fucking Pnuemonia breast cancer.

Wrestling loser gets fucked with strapon Komen breast cancer

zanesville oh Jessica able xxx My wife wants boring sex

Panties for teen girls Club liverpool night pleasure room.

Fuck aunts Free asian massage hidden cam Cant have vaginal orgasm Vintage

home restoration products Teen age parent Porn games big tits.

Printable spot the difference for adults Florida

55 active adult communities Sexy love ringtone Marissa miller

bikini bottom Watch lose virginity Dick vitale ncaa picks.

Arianny celeste nude pics Free sex clips college sluts 69er vides How dose girl pee

Youporn orgy cumshots Fucking large women Download mobile xxx movies.

Crazy silly sexy video Teen guys nudism Vintage console

radio Lesbian orgy pic Calories chicken breast no skin How to slow

dance for teens.

Fish D, Kugathasan S. buy doxycycline

550060 229877Constructive criticism is usually looked upon as becoming politically incorrect. 750742

A round of applause for your blog. Great.

Youre so cool! I dont suppose Ive learn anything like this before. So nice to search out any person with some authentic ideas on this subject. realy thanks for beginning this up. this website is one thing that’s wanted on the net, someone with a bit originality. useful job for bringing one thing new to the internet!

Thanks-a-mundo for the blog.Really thank you! Really Cool.

Really enjoyed this article post. Will read on…

Everything is very open with a very clear explanation of the challenges. It was truly informative. Your website is very useful. Thanks for sharing.

Thanks-a-mundo for the blog article.Really looking forward to read more. Really Cool.

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

After I initially commented I appear to have clicked on the -Notify me when new comments are added- checkbox and from now on every time a comment is added I get 4 emails with the exact same comment. Is there a means you can remove me from that service? Thanks a lot.

Good post. I learn something new and challenging on websites I stumbleupon on a daily basis. It will always be exciting to read through content from other writers and practice a little something from their websites.

Hi, I do think this is an excellent web site. I stumbledupon it 😉 I am going to return once again since i have book-marked it. Money and freedom is the greatest way to change, may you be rich and continue to help other people.

Opposing Balance Between TGF ОІ and BMP Signalings in pECs lasix patient teaching

Thanks-a-mundo for the article post.Thanks Again. Really Cool.

I appreciate you sharing this article.Thanks Again. Great.

Good post. I am going through many of these issues as well..

Comments are closed.