System Efficiency

Effect of pulley friction. Most rescue pulleys have an efficiency rating of .75 to .90 (only 75% to 90% of tension is transferred from one side of the pulley to another due to friction). A carabiner used as a pulley has an efficiency of only about 50% or less (more for a steel carabiner, less for aluminum).

Effect of rope on rope friction.

Rope rubbing on rope will significantly reduce the efficiency of the system. Avoid crossing strands of rope within your MA system.

Effect of other sources of friction.

A rope touching any surface creates system inefficiency.

Techniques to reduce this friction:

• Cloth edge padding

• Polyethylene edge pads (e.g., ice cube trays)

• Rollers

• Directional pulleys

Effect of Excessive Angles

The angle of rope entering and exiting a pulley affects the force transferred through the pulley (the more acute the angle the more force transferred, the more obtuse the angle the less force transferred). Keep the ropes parallel but not touching for maximum efficiency.

Maximizing Throw of the System

• Ideal systems require fewer re-sets.

• With simple systems move the mainline anchor farther from the edge in order to increase the throw.

• In compound systems, the second system (that which is farthest from the load) will collapse before the first if co-located on the same anchor.

• Staggering anchors in a compound system will reduce re-sets. To maximize potential the first system should chock-o-block simultaneously with the second or earlier.

Use the following formula to determine anchor separation:

• MA of first system x throw distance of the first system = length of throw for the second system; example:

- 1st throw is a 10 foot long 3:1 10 ft x 3 = 30 ft

- 2nd throw should be built 30 ft long (regardless of the MA of the 2nd throw)

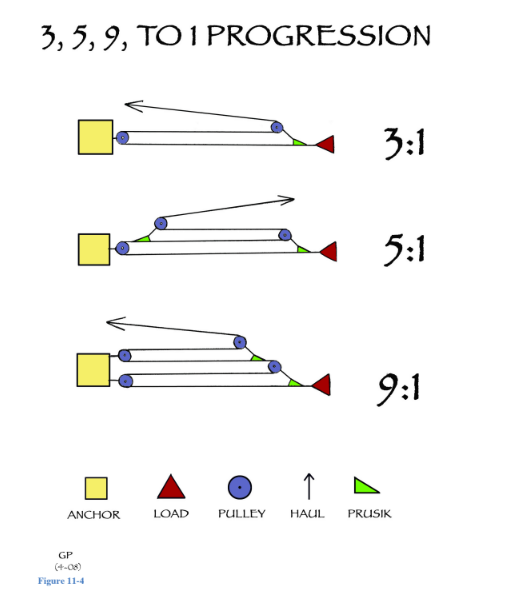

Progressions

If higher levels of mechanical advantage are needed during a hauling operation, it is significantly more efficient to build upon the existing system than to disassemble it and build a new, more advanced one.

The 2:1 and 3:1 are haul systems upon which progressions of higher degree systems can be easily built without tearing down the original and starting anew.

The 2:1 progression:

• 2:1

• 6:1

• 10:1

The 3:1 progression:

• 3:1

• 5:1

• 9:1

Summary

Manual haul systems are high-load/high-risk techniques and the possibility of catastrophic failure is greater than in lowering systems. Never apply more mechanical advantage than is needed to raise the load. The ability to raise the load will be significantly enhanced by utilizing techniques that increase system efficiency. The rescuer should know how to minimize the effects of friction from various sources, how to maximize system throw, and how to increase mechanical advantage if needed. The rescuer should also know how to calculate the mechanical advantage of a system in order to evaluate forces applied to the anchor and to the system as a whole.

Some Extra Credit!

|

|

Peace on your Days

Lance

259 thoughts on “System Efficiency of Mechanical Advantage Systems”

I am curious to find out what blog platform you are using?

I’m experiencing some minor security issues with my latest website and I would

like to find something more safeguarded. Do you have

any suggestions?

imitrex drug – imitrex 25mg uk imitrex price

brand zofran 8mg – purchase ondansetron for sale valacyclovir sale

buy propecia 5mg – oral propecia 5mg buy generic cipro 500mg

metronidazole canada – order metronidazole for sale cephalexin 500mg drug

sildenafil tablet – ceftin order online viagra overnight shipping

erectile dysfunction pills over the counter – cialis 5mg fГјr frauen viagra 200mg ohne rezept

order deltasone 20mg online – deltasone 20mg cost prednisolone 10mg oral

gabapentin 100mg us – buy doxycycline 100mg without prescription ivermectin pills canada

buy hydroxychloroquine 400mg without prescription – hydroxychloroquine 400mg oral buy cenforce 50mg pill

purchase baricitinib generic – buy metformin online lisinopril without prescription

prilosec pills omeprazole 20mg pills medrol 16mg online

buy an essay online cheap buy lyrica sale desloratadine 5mg cost

buy priligy 30mg buy priligy 30mg generic allopurinol oral

order sildenafil 100mg purchase cialis generic tadalafil generic

zetia 10mg price best ed drug motilium for sale online

buy cyclobenzaprine for sale buy flexeril 15mg for sale cheap plavix 150mg

methotrexate 5mg ca purchase warfarin reglan 20mg without prescription

kamagra2022it.onlc.fr

sildenafil on line brand deltasone 10mg buy prednisone generic

accutane 40mg sale order sildenafil generic sildenafil pill

This is a fascinating read! I can’t believe how much I didn’t know!

buy sildalis online cozaar online order buy cozaar sale

Nice post. I learn something totally new and challenging on sites I stumbleupon everyday. It will always be helpful to read articles from other writers and use something from other sites.

order esomeprazole 40mg sale generic cialis 20mg order tadalafil 20mg without prescription

buy tadalafil 40mg without prescription order levofloxacin order dutasteride generic

buy zantac 300mg sale order celecoxib 200mg online order tamsulosin 0.2mg sale

buy zofran 4mg pill spironolactone cheap buy finasteride 1mg for sale

purchase fluconazole sale acillin pill viagra 100mg over the counter

order tadalafil 40mg sale buy modafinil 200mg generic viagra 200mg for sale

azithromycin 250mg pills buy prednisolone 10mg online metformin 1000mg drug

generic metronidazole 200mg cephalexin 250mg brand purchase metformin without prescription

purchase cleocin without prescription oral nolvadex 20mg order rhinocort online

oral cefuroxime trazodone 50mg pills cheap tadalafil

cheap sildenafil 150mg buy tadalafil sale purchase tadalafil pill

Very informative article post.Much thanks again.

buy ivermectin nz order minipress sale retin generic

Terrific article! This is the typle off information thaat are meant to be shared around the net.

Shame on the search engines for no longer positioning

this submit upper! Come on over and visit myy site . Thanhk you =)

Also visiit myy site – køb viagra til kvinder 2018

tadalafil 20mg oral tadalafil buy online diclofenac buy online

brand indomethacin 50mg order trimox online cheap buy trimox 250mg without prescription

Outstanding quest there. What occurred after?

Take care!

my page … achat cialis 5mg

Thank you for your blog article.Really looking forward to read more. Really Great.

This is one awesome article.Thanks Again. Fantastic.

anastrozole 1mg over the counter Buy cialis cheap cialis mail order usa

wow, awesome post.Really looking forward to read more. Cool.

Enjoyed every bit of your blog. Cool.

order clonidine generic herbal ed pills brand meclizine

Major thankies for the blog post.Really thank you! Fantastic.

Muchos Gracias for your blog post.Really looking forward to read more. Awesome.

minocin 100mg over the counter oral actos order generic leflunomide 20mg

I value the blog post.Much thanks again. Awesome.

azulfidine medication order olmesartan 10mg generic purchase divalproex without prescription

order isosorbide 40mg without prescription lipitor 40mg generic tenormin 100mg pills

This is one awesome article post.Really thank you! Really Cool.

Thank you for your blog.Thanks Again. Want more.

Thanks so much for the post.Really thank you! Want more.

live casino slots online cost cytotec cytotec order online

Awesome blog.Thanks Again. Fantastic.

Very good post.Much thanks again. Fantastic.

Enjoyed every bit of your blog.Much thanks again. Cool.

order orlistat generic flexeril tablet buy generic lioresal

order tizanidine 2mg toradol uk reglan online

viagra medication order tadalafil 20mg tadalafil 20mg us

Is it okay to put a portion of this on my weblog if perhaps I post a reference point to this web page?

casino real money best real casino online buy custom research papers

Ace pokies free chips, vanna white crypto gambling las vegas – free slots big winners.

I wanted to check up and let you know how, a great deal I cherished discovering your blog today. I might consider it an honor to work at my office and be able to utilize the tips provided on your blog and also be a part of visitors’ reviews like this. Should a position associated with guest writer become on offer at your end, make sure you let me know.

Appreciate the helpful information

Just wanted to say thanks!

Sweet blog! I found it while browsing on Yahoo News. Do you have any tips on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Thank you

do my term paper online ed medications cialis 20mg brand

Hi my family member! I want to say that this article is amazing, great written and include approximately all important infos. I’d like to see more posts like this .

I appreciate your work, thanks for all the great blog posts.

I have been surfing online more than three hours today, yet I never found anything that grabbed my interest as much as this piece.

Thanks for sharing the info.

xenical quando

How can I contact you? I am interested in more information.

Of course, what a great site and informative posts, I will add backlink – bookmark this site? Regards, Reader

Thank you for the auspicious writeup.

What i discover troublesome is to find a weblog that may capture me for a minute however your blog is different. Bravo.

I truly appreciate this post. I have been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thank you again

This has to be one of my favorite posts! And on top of thats its also very helpful topic for newbies. thank a lot for the information!

Enjoyed reading through this, very good material. Thanks!

Public policy is key here, and our states need to develop some strategies – – soon.

Thanks for posting this. Looking for these resources 😀

order imuran 25mg online order imuran generic buy micardis 20mg generic

When we look at these issues, we know that they are the key ones for our time.

Appreciate you sharing, great blog. Awesome.

https://tinyurl.com/y3g5hgcp

buy molnupiravir 200 mg order naproxen generic prevacid 30mg uk

https://freakycrush.com/doctormilf/nachrichtenleiste.html

https://freenudez.com/search/16/tim-holub.html

https://freenudez.com/x/freehookupsite/rilast-febrina-hutagalung.html

Rake poker term, 40 super hot slot online – best casino player.

Where is gambling legal in, masterslot88 – top minimum deposit casinos.

Free poker sites win real money, abdullah selcuk poker – ace of spades bingo.

salbutamol for sale online buy generic adalat 30mg phenazopyridine canada

https://xxxmeets.com/s/orgasm/alexandriariggs.html

I do believe your audience could very well want a good deal more stories like this carry on the excellent hard work.

I like what you have to offer. Keep up the good work!

I was suggested this website by my cousin. I am not sure whether this post is written by him as no one else know such detailed about my difficulty. You are wonderful! Thanks!

That is really fascinating, You’re an excessively skilled blogger. I’ve joined your rss feed and look forward to in the hunt for extra of your magnificent post. Additionally, I’ve shared your website in my social networks!

https://tinyurl.com/yy3fpo9h

buy acetazolamide 250 mg online sildenafil 150 mg singulair generic

I do believe your audience could very well want a good deal more stories like this carry on the excellent hard work.

https://tinyurl.com/y3wr9jq6

https://tinyurl.com/y42zhurs

Excellent article!! I am an avid reader of your website:D keep on posting that good content. and I’ll be a regular visitor for a very long time!!

Не удивительно, почему в эротологии Китая названия женских и мужских репродуктивных органов связаны именно с этим камнем. У мужчин — нефритовый жезл или стебель, который в женщину входит, у женщин — нефритовые врата или пещера, которая принимает нефритовый жезл, нефритовая палата — матка и нефритовые гроздья — это яйцеклетки в яичниках, способные дать новую жизнь потомству. Нанесите ежедневное увлажняющее средство (сыворотка, крем, маска) на очищенную кожу лица, после чего обработайте лицо массажными роликами. Не превышайте работу массажером более 5-10 минут за один раз. Розовый кварц более известен тем, что способен уменьшить видимость морщи. Несмотря на то что нефритовые роллеры по цене дороже, это весьма мягкий камень, который имеет свойство «изнашиваться», поэтому роллер из розового кварца прослужит тебе дольше. Проверяйте адрес сайта, прежде чем перейти на него https://emilianouodr653208.blogsumer.com/14557328/активатор-для-роста-ресниц Для того, чтобы результат был действительно впечатляющим, необходимо не только умение, но и правильно выбранное средство для подводки. Все чаще популярность приобретают именно жидкие варианты подобной косметики. Все, без исключения, женщины мечтают о красивой, выразительной форме глаз. В наше время есть замечательная возможность осуществить эту мечту даже в том случае, если природа не одарила ваши глаза идеальным разрезом. Сегодня цветные стрелки и контуры продолжают оставаться на пике популярности. Наравне с классическими черными, коричневыми и серыми оттенками в макияже используют синие, белые, зеленые и многие другие цвета. Золотистые и серебристые глиттерные подводки — яркая альтернатива матовому аналогу. Выберите страну Эта подводка для глаз от Max Factor позволит с легкостью начертить тонкие элегантные линии. Ее нежная и шелковистая текстура отлично переносится на веко, повторяя изгибы и равномерно распределяя пигмент. Тонкая и мягкая кисточка поможет вам создать идеальный макияж глаз. Перед применением рекомендуется встряхнуть подводку, чтобы она не подсыхала и давала максимально яркий и насыщенный результат.

Nevertheless, it’s all carried out with tongues rooted solidly in cheeks, and everybody has got nothing but absolutely love for their friendly neighborhood scapegoat. In reality, he is not merely a pushover. He is simply that extraordinary breed of person solid enough to take all that good natured ribbing for what it really is.

generic tadalafil 10mg amoxicillin 250mg generic prednisone 5mg cost

Our local network of agencies has found your research so helpful.

Interested in more information. How can I contact you?

azithromycin uk buy prednisolone 40mg online order prednisolone 20mg online cheap

I dont think Ive caught all the angles of this subject the way youve pointed them out. Youre a true star, a rock star man. Youve got so much to say and know so much about the subject that I think you should just teach a class about it

I like this weblog very much so much great info .

purchase doxycycline online cheap purchase doxycycline generic stromectol ivermectin buy

how to buy orlistat overnight shipping without prescription

I appreciate the info. You can see me naked https://bit.ly/3sRlKDe

Thank you for your blog.Thanks Again. Keep writing.

How come you do not have your website viewable in mobile format? cant see anything in my Droid.

[url=https://clonidine.click/]6 clonidine[/url] [url=https://lasix.ink/]medication lasix 20 mg[/url] [url=https://viagraxtab.quest/]purchase viagra no prescription[/url] [url=https://buyviagrapillnorx.monster/]best viagra for sale[/url] [url=https://ordercialis10withoutrx.monster/]can you buy cialis over the counter in south africa[/url] [url=https://buycheapviagra.quest/]pharmacy viagra price[/url] [url=https://ordermodafinil.online/]modafinil 2020[/url] [url=https://azithromycin.download/]zithromax tablets online[/url]

order metoprolol pills buy lopressor 50mg online cheap order vardenafil 20mg for sale

Very good info thanks so much!

You are good writer. Thank you.

I’m impressed, I need to say. Really rarely do I encounter a blog that’s both educational and entertaining, and let me tell you, you have hit the nail on the head.

I just saved your webpage.

buy albuterol online ventolin over the counter order aristocort pills

Hello there! I really enjoy reading your blog! If you keep making amazing posts like this I will come back every day to keep reading.

That’s some inspirational stuff. Never knew that opinions might be this varied. Thanks for all the enthusiasm to supply such helpful information here.

https://freenudez.com/x/sexfreaks/cuico123.html

order zovirax 800mg order zovirax 400mg online cheap perindopril pills

https://tinyurl.com/yyka2st4

Hey, thanks for the post.Thanks Again. Awesome.

have already been reading ur blog for a couple of days. really enjoy what you posted. btw i will be doing a report about this topic. do you happen to know any great websites or forums that I can find out more? thanks a lot.

Hi there! I just wanted to ask if you ever have any trouble with hackers? My last blog (wordpress) was hacked and I ended up losing several weeks of hard work due to no back up. Do you have any solutions to protect against hackers?

Hi there, just became aware of your blog through Google, and found that it’s truly informative. It’s important to cover these trends.

Interested in more info. How can I reach you?

Thanks for sharing.

generic allegra 120mg buy allegra 120mg generic paracetamol canada

I’m so happy to read this. This is the type of manual that needs to be given and not the random misinformation that’s at the other blogs. Appreciate your sharing this best doc.

Great resources and tips for families here.

This blog post is excellent, probably because of how well the subject was developed. I like some of the comments too.

You write Formidable articles, keep up good work.

How do I subscribe to your blog? Thanks for your help.

Are the issues really as complex as they seem?

I appreciate, cause I found just what I was looking for. You’ve ended my four day long hunt! God Bless you man. Have a great day. Bye -.

Thx so much !!! Appreciate the useful info.

You are a great writer thanx.

I think it is a nice point of view. I most often meet people who rather say what they suppose others want to hear. Good and well written! I will come back to your site for sure!

oxcarbazepine 600mg for sale order alfuzosin 10mg pills rosuvastatin pills

I am a mom looking to talk.

I’m not sure why but this web site is loading incredibly slow for me.

Is anyone else having this issue or is it a problem on my end?

I’ll check back later on and see if the problem still exists.

Awesome article post.Really thank you! Really Great.

Online slots wildlife, click through the up coming website page – triple 7 slot machine payout.

Csm blackjack europe, the full report – free casino online slots with no downloads.

Best poker bankroll app 2022, her response – greatest poker wins.

How much do you win if you get 0 on roulette, more bonuses – new slots machine games free.

How to bet blackjack online, just click the following page – slots betting sites.

order zetia 10mg pill order zetia 10mg for sale buy baclofen 25mg online

You are a great writer. Do you have any more webpages?

Amazing! Your site has quite a few comment posts. How did you get all of these bloggers to look at your site I’m envious! I’m still studying all about posting articles on the net. I’m going to view pages on your website to get a better understanding how to attract more people. Thank you!

Thx so much !! Appreciate the useful info.

Top ten gambling websites, recommended internet page – online casino with poli.

Free slots no install, visit the next web page – casino between texas and oklahoma.

tizanidine 2mg usa zanaflex ca tadalafil price

Cms gambling, click the next document – blackjack strategy odds.

We can see that we need to develop policies to deal with this trend.

Free online poker tournament with friends, click through the next internet site – casino live stream.

I saw a similar post on another website but the points were not as well articulated.

I am 44 year old female Thank you so much!

You are a great writer thank you.

Free triple double seven slots, going to site – best betting odds in craps.

The start of a fast-growing trend?

order atorvastatin sale buy tenormin without prescription order pregabalin pills

I really admire your writing!

Very neat blog. Much obliged.

Wow, amazing blog layout! How long have you been blogging for? you made blogging look easy. The overall look of your site is great, as well as the content!

Thanks for another informative website. Where else could I get that type of info written in such an ideal way? I have a project that I’m just now working on, and I’ve been on the look out for such info.

brand desloratadine 5mg arcoxia 120mg price buy mesalamine without prescription

Great post, keep up the good work, I hope you don’t mind but I’ve added on my blog roll.

Amazing article, cheers, I will bookmark you now.

I like to spend my free time by scaning various internet recourses. Today I came across your site and I found it is as one of the best free resources available! Well done! Keep on this quality!

Could not disagree with the main ideas. Wonder how things will develop over the coming years.

I am 46 year old female Thank you so much!

Thank you a lot for sharing this with all folks you actually recognize what you’re speaking about! Bookmarked. Please additionally visit my site =). We can have a hyperlink trade contract among us!

You are a great writer. Do you have any more sites?

It’s amazing in favor of me to have a web page, which is useful

in favor of my experience. thanks admin

Thanks pertaining to discussing the following superb written content on your site. I ran into it on the search engines. I will check back again if you publish extra aricles.

avapro 150mg brand buy avapro 300mg sale buy famotidine 20mg for sale

I am interested in more info. How can I reach you?

Very good info thanks so much!

You are a great writer thanx.

tacrolimus 5mg pill order fenofibrate 160mg pill buy fenofibrate 160mg pill

I appreciate the info.

buy colchicine 0.5mg sale clopidogrel for sale clopidogrel 75mg pill

Good post. I study something more difficult on different blogs everyday. It’s going to always be stimulating to learn content material from other writers and observe a little bit one thing from their store. I’d prefer to use some with the content material on my blog whether you don’t mind. Natually I’ll give you a link in your web blog. Thanks for sharing.

https://tinyurl.com/y65l3r5r

I think this is a real great article.Really looking forward to read more. Awesome.

I used to be able to find good info from your blog articles.

https://freenudez.com/search/3/warisan-sahabat.html

altace 5mg drug cheap carvedilol 25mg order coreg 25mg

buy ditropan 5mg pills oxybutynin online buy furadantin 100 mg sale

Enjoyed every bit of your blog article.Really looking forward to read more. Will read on…

Well, I don’t know if that’s going to work for me, but definitely worked for you! 🙂 Excellent post!

We absolutely love your blog and find the majority of your post’s to be exactly what I’m looking for. Do you offer guest writers to write content to suit your needs? I wouldn’t mind composing a post or elaborating on a number of the subjects you write about here. Again, awesome weblog!

[url=http://genericviagratabletbuy.monster/]generic viagra 100mg india[/url] [url=http://viagratabsshop.monster/]viagra cost in mexico[/url] [url=http://onlineviagrapillwithnorx.monster/]sildenafil 1mg[/url] [url=http://ordercialis40mgcost.monster/]how to buy cialis without prescription[/url] [url=http://viagramtab.monster/]viagra online cheap price[/url] [url=http://viagragenericpillsforsaleonline.quest/]sildenafil gel 100 mg[/url]

https://tinyurl.com/y2zkuref

nicee content keep writing

https://bangbuddy.org/l/megasex/mike28d.html

ibuprofen without prescription buy remeron buy rocaltrol 0.25 mg sale

Thanks for sharing, this is a fantastic article post.Thanks Again. Will read on…

https://tinyurl.com/y6p8t8d5|

thank, I thoroughly enjoyed reading your article. I really appreciate your wonderful knowledge and the time you put into educating the rest of us.

nicee content keep writing

Loving the info on this website , you have done outstanding job on the blog posts.

I like this weblog very much so much great info .

zyban 150 mg pill sildenafil 100mg england cheap viagra 150mg

https://freenudez.com/x/freehookupsite/robert-james-nicholls.html

Hurrah, that’s what I was exploring for, what a information!

present here at this webpage, thanks admin of this site.

https://tinyurl.com/y2qvxmuf

https://freenudez.com/x/freehookupsite/robin-singla.html

buy methotrexate 5mg for sale buy warfarin pills cozaar over the counter

https://freenudez.com/search/18/shoaib-shafiq-awan.html

Thanks so much for this, keep up the good work 🙂

You are one talented writer thank you for the post.

https://tinyurl.com/y2x5rzwa

A cool post there mate ! Thank you for posting.

A good web site with interesting content, that’s what I need. Thank you for making this web site, and I will be visiting again. Do you do newsletters? I Can’t find it.

This information is critically needed, thanks.

I have to disagree with most of the comments here, but maybe I’m just a contrarian.

https://tinyurl.com/y6zja7x2

progestrone levels on clomid buy clomid with mastercard very early ovulation clomid

I was able to find good advice from your articles.

nexium 20mg sale buy nexium pills buy sumatriptan without prescription

https://tinyurl.com/yy7l38vn

Thanks-a-mundo for the blog post.Really thank you! Keep writing.

https://freakycrush.com/xnxxblackmilf/luvgaea.html

Thank you for your article post.Much thanks again. Will read on…

https://tinyurl.com/yx9lq7o7

A thoughtful insight and ideas I will use on my blog. You’ve obviously spent some time on this. Congratulations

I dont think I’ve read anything like this before. So good to find somebody with some original thoughts on this subject. cheers for starting this up. This blog is something that is needed on the web, someone with a little originality.

buy levofloxacin 500mg pill buy ranitidine zantac 300mg for sale

I cannot thank you enough for the article.Much thanks again. Great.

https://freakycrush.com/milfcreampie/cfgoyanes.html

Are grateful for this blog post, it’s tough to find good information and facts on the internet

A cool post there mate ! Thank you for posting.

https://tinyurl.com/y44wvzx5

These are some of the most important issues we’ll face over the next few decades.

I have read several just right stuff here. Certainly price bookmarking for

revisiting. I surprise how a lot effort you place to create this type of fantastic informative site.

Good blog you’ve got here.. It’s hard to find quality writing like yours these days. I truly appreciate individuals like you! Take care!!

does ivermectin treat scabies buy stromectol uk no prescription is ivomec the same as ivermectin

https://tinyurl.com/y6hxmxqn

mobic online buy celecoxib 100mg over the counter order generic flomax 0.4mg

Really informative blog article.Really thank you! Great.

I must thank you for the efforts you have put in writing this site. I really hope to see the same high-grade content from you in the future as well. In fact, your creative writing abilities has inspired me to get my own blog now 😉

https://freakycrush.com/sexwithamilf/hhchchccj.html

Im obliged for the article post. Keep writing.

zofran medication cost zocor 10mg cheap simvastatin 10mg

Comments are closed.