Thanks to Peak Rescue Institute Full Video at the bottom!

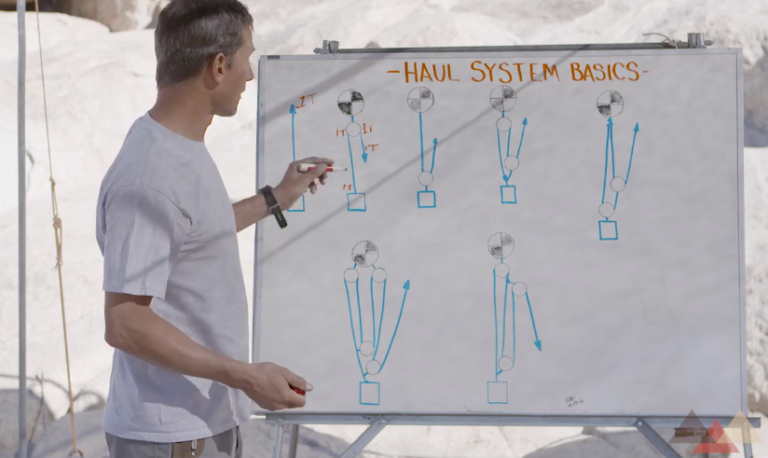

In general, the Ideal Mechanical Advantage (IMA) is the ratio between the distance the load moves and distances the haul team moves. In a 2:1 system the load will move 1′ to every 2′ of haul. However, this does not mean that lifting the load is twice as easy.

The Practical Mechanical Advantage (PMA), or simply put, the efficiency of the system, is the actual physical advantage the haul team ends up with. In short, based on the size of the haul team, try to build the MA system as small as possible. More pulleys create more friction, resulting in efficiency loss.

Consider the hauling field; that is to say, configure the MA system in a way that maximizes that amount of ground area the haul team can operate. This will also minimize the number of re-sets of the haul system. Build the MA system clean. Avoid crossed or twisted lines, as this will add unwanted friction in the system.

Ideally, when you make contact with a patient and you package a patient, you want to be able to use gravity to your benefit and just lower the patient. And that’s generally a relatively lower risk operation than raising a patient. But sometimes due to access issues or other issues, you may need to actually raise a patient back up toward where the team’s working above.

|

|

|

When it’s time to raise a patient, you’re going to need to build a haul system. When we’re talking about haul systems, we’re talking about using pulleys and carabiners and rope grab devices to basically create systems that magnify the effort that we’re putting into a rope system. I can take a rope that’s attached to a rescue load and just pull directly on that. I may be able to move the load that way. That would be ideal, a perfect feel for the load and it’s the easiest way. It would be the easiest way to move a load. So whatever amount of force that I can put into this system in terms of pulling on the load is the amount of force that’s imparted to the load. Often, however, with the size, the weight of the loads that we’re working with in the rescue world, a straight pull on the rope isn’t going to be enough.

Another way that I might give myself a little bit of an advantage over just a straight pull on the rope is to put the rope through a pulley attached to an anchor. This pulley serves as what we call a change of direction. A reason I might do this is to put myself in a more advantageous position. For instance, I’m pulling downhill and using gravity and my weight to help pull the load up the hill.

|

|

The amount of tension that I put into the pulley is transmitted through the pulley and down the rope to the load. If I can hang enough weight on this change of direction pulley, I can actually move the load uphill. So basically, the amount of tension that I put in is the same amount of tension that is transmitted to the load through the pulley.

One of the simplest mechanical advantage systems we can build is a two to one mechanical advantage system. And that’s essentially just attaching a pulley to the load, bringing the bitter end of the rope back up to the anchor and then pulling on the load… And this gets into the basic concept of haul systems and mechanical advantage systems where we use pulleys.

One of the simplest mechanical advantage systems we can build is a two to one mechanical advantage system. And that’s essentially just attaching a pulley to the load, bringing the bitter end of the rope back up to the anchor and then pulling on the load… And this gets into the basic concept of haul systems and mechanical advantage systems where we use pulleys.

Pulleys have a doubling effect. What that means is if I put an amount of force into one side of a pulley, it has to balance around that pulley. So when I pull with the amount of force that I’m able to pull with, that same amount of force is transmitted around the pulley to the other side of the pulley. It’s supported by the anchor and the load feels double the force that I’m putting in.

So if I find a two to one haul system’s not sufficient, I can start building up more and more mechanical advantage. The next obvious step would be to move to a three to one. In this case, the rescue rope is actually attached directly to the load, comes up through a change of direction pulley, and then goes down through what we call a haul pulley.

A haul pulley is a pulley that’s in the system that’s moving and performing work. So what we have here is a three to one haul system. And once again, back to our concept of pulleys transmitting and doubling forces, let’s talk about that in terms of this system. I put a certain amount of force. I’m able to impart a certain amount of force into this system.

That amount of force is transmitted around the pulley and out the other side. So the amount of force that I’m putting in is the same amount of force that’s on this line. And we find that it creates a doubling of that force that transmits down to this rope grabber (prusik). That force continues up to my change of direction pulley, goes through it, transmits out the other side, and it comes down. And we can actually add that amount of force to the rope grab device. So I’ve got force plus force, two times that force. That force continues around and actually adds to the doubled force here. So I have three times the amount of force that I put into this system.

That amount of force is transmitted around the pulley and out the other side. So the amount of force that I’m putting in is the same amount of force that’s on this line. And we find that it creates a doubling of that force that transmits down to this rope grabber (prusik). That force continues up to my change of direction pulley, goes through it, transmits out the other side, and it comes down. And we can actually add that amount of force to the rope grab device. So I’ve got force plus force, two times that force. That force continues around and actually adds to the doubled force here. So I have three times the amount of force that I put into this system.

All right. Moving back to our first example, the first system that we showed, which was basically just a straight pull on a rope attached to a load. Basically, the force that’s imparted into one end of the rope is transmitted down the rope to the load. So if I have a load that weighs 100 pounds, if I’m able to pull slightly more than 100 pounds, I’ll be able to lift that. I’ll be able to lift that load just pulling straight on the rope. We have a system that we can use to help analyze this. And we can actually analyze a haul system or a mechanical advantage system, any system, and we can determine what its mechanical advantage is. And when we’re talking about this mechanical advantage, we’re talking about theoretical mechanical advantage. So that eliminates real world friction, all things like the friction that’s introduced by the inefficiency of a pulley, all of that. This is mechanical advantage in the perfect world.

But instead of talking about whatever amount of force or amount of pounds I’m able to generate hauling on a rope, let’s just assign a variable to that. And we’ll just say it’s one unit and we’ll call it one unit of tension. So that’s one T. So if I put one unit of tension … And my one unit of tension as a hauler, I may be able to pull on a rope … I may be able to put 60 pounds of tension in a rope by pulling on it in any kind of sustained manner. But that doesn’t matter. We’re just going to call it one unit of tension. That one unit of tension transmits down the rope to one unit of tension applied to the load. And again, if I can generate enough tension that is slightly more than the mass of the load or the weight of the load, then I can move that load.

Now, moving over to our second example of putting a change of direction pulley into our system. Again, I may do that so that I can use gravity and I can use a slope to help me pull against the load. I’m always going to start my one unit of tension, my haul force where I grab onto the rope, where the rope enters the system. And I’m going to follow it up. I’m going to follow it continuously through the system. So on one side of the pulley, I have one T. That one T is transmitted around the pulley and it comes out the other side. It continues down the line to the load. So pulling through a change of direction pulley attached to an anchor, I’m generating still, just like pulling it straight in line, I’m generating one unit of tension on my load.

The next system we just showed was a two to one haul system. Now we’re actually starting to get into using the nature of a pulley to help generate additional force for us to help us move a load. Let’s apply our T method here. One T as always. That’s what we start with on the haul strand of rope, transmitted down to our pulley. One T goes around our pulley, one T. Because we have one T on one side of the pulley, one unit of tension on one side of the pulley, one unit of tension on the other side of the pulley, that actually translates into two units of tension that’s felt by our load. That one unit of tension continues up the rope. And it ends at the anchor as one T.

The next system we just showed was a two to one haul system. Now we’re actually starting to get into using the nature of a pulley to help generate additional force for us to help us move a load. Let’s apply our T method here. One T as always. That’s what we start with on the haul strand of rope, transmitted down to our pulley. One T goes around our pulley, one T. Because we have one T on one side of the pulley, one unit of tension on one side of the pulley, one unit of tension on the other side of the pulley, that actually translates into two units of tension that’s felt by our load. That one unit of tension continues up the rope. And it ends at the anchor as one T.

Now, next let’s move on to our three to one haul system. One T transmitted down the line to our first pulley. One T comes out, one T. One T goes in, one T comes out. So we can say that two T is transmitted down through the prusik rope grab device. And we’ll just leave that there for now. We don’t want to break our stream in following the rope through the system. We have one T coming out of the pulley. One T comes up to this change of direction pulley on our anchor. One T comes out, continues down. We run into our two T here where we add it together. And we have three T or a three to one haul system.

Peace on your Days!

Lance

196 thoughts on “Mechanical Advantage, Part 1”

buy sumatriptan generic – imitrex 50mg us buy sumatriptan sale

It’s genuinely very complex in this full of activity life to listen news on Television, so I only use web for

that reason, and obtain the latest information.

buy zofran 4mg generic – cost spironolactone 25mg valacyclovir 500mg canada

finasteride online buy – cipro 1000mg pills cipro uk

oral flagyl – buy sulfamethoxazole buy cephalexin 250mg online

fildena 100mg us – desyrel buy online viagra 50mg pill

red ed pill – top erection pills sildenafil 100mg fГјr mГ¤nner

deltasone pill – amoxicillin for sale buy generic prednisolone 10mg

order generic gabapentin 600mg – neurontin 100mg drug cost ivermectin

hydroxychloroquine 200mg brand – sildenafil 50mg price order cenforce generic

baricitinib 2mg brand – order amlodipine 5mg pill order lisinopril 5mg online cheap

cheap omeprazole 20mg order prilosec 20mg pill methylprednisolone online

buying a term paper ventolin inhalator us order clarinex for sale

buy priligy 30mg without prescription priligy uk order allopurinol sale

buy viagra 150mg pills cheap tadalafil without prescription cheap tadalafil

zetia pill buy tetracycline 500mg pill motilium price

flexeril medication buy colchicine pill plavix pills

order methotrexate 5mg for sale brand methotrexate 10mg purchase reglan sale

brand sildenafil 100mg cialis 10mg pill buy deltasone 40mg sale

buy isotretinoin 20mg generic purchase sildenafil for sale buy generic aurogra 100mg

sildenafil for sale sildenafil drug cozaar 25mg canada

Nice post. I learn something totally new and challenging on sites I stumbleupon everyday. It will always be helpful to read articles from other writers and use something from other sites.

order nexium 20mg generic sildenafil 150mg for sale tadalafil 20mg price

cialis mail order imitrex price purchase dutasteride pills

play blackjack online real money usa real money online blackjack blackjack bonus online

buy ranitidine 300mg without prescription purchase tamsulosin generic flomax 0.4mg price

order zofran 4mg online cheap purchase finasteride generic

video poker machine games electronic hand held poker game real poker games online

purchase diflucan generic fluconazole 100mg cheap viagra online order

best place for sports betting betting apps for sports bet on sports games app

order tadalafil 40mg purchase modafinil sildenafil generic

azithromycin 500mg for sale cost glucophage 500mg buy metformin 500mg generic

flagyl pills buy cephalexin 125mg online cheap metformin 1000mg canada

cleocin order online clindamycin ca purchase budesonide online cheap

sports betting new york state mgm sports bet online sports betting minnesota

buy ceftin 250mg pills ceftin 250mg generic order tadalafil 5mg pill

viagra 50mg tablet generic cialis 20mg cialis pill

stromectol 2mg purchase tretinoin without prescription buy retin for sale

Very neat blog. Fantastic.

tadalis buy online order generic tadalafil 10mg diclofenac online buy

Awesome blog post.Really looking forward to read more. Much obliged.

indocin tablet purchase indocin without prescription brand amoxicillin 250mg

Say, you got a nice blog article.Thanks Again. Really Cool.

arimidex 1mg price Buy cialis now buy cialis 20mg online cheap

Great blog post.Really looking forward to read more. Great.

buy generic clonidine 0.1mg catapres 0.1mg for sale antivert 25 mg uk

I really liked your post.Really looking forward to read more. Really Great.

Thanks for sharing, this is a fantastic blog post.Really thank you! Keep writing.

minocycline 100mg brand order actos 30mg for sale leflunomide 20mg canada

Thank you ever so for you blog article.Really thank you!

easy sports betting sports betting casino william hill sports betting odds

Wow, great article.Really thank you! Really Cool.

buy azulfidine sale divalproex 500mg drug depakote us

Thanks so much for the blog article.Thanks Again. Keep writing.

buy isosorbide 20mg tenormin 100mg price atenolol generic

I think this is a real great blog article.Much thanks again. Will read on…

I really liked your article.Really thank you!

Nice read, I just passed this onto a friend who was doing a little research on that. And he actually bought me lunch as I found it for him smile Thus let me rephrase that: Thanks for lunch! “High living and high thinking are poles apart.” by B. J. Gupta.

essay writer service uk nursing student clinical experience essay essay on customer service

online casinos generic loratadine buy misoprostol generic

Im grateful for the blog post.Really looking forward to read more.

Very good blog. Great.

orlistat 60mg uk xenical 120mg cost buy lioresal

tizanidine uk metoclopramide generic reglan usa

sildenafil for men cialis sales generic cialis india

While this issue can vexed most people, my thought is that there has to be a middle or common ground that we all can find. I do value that you’ve added pertinent and sound commentary here though. Thank you!

best online casino real money viagra pills 100mg paper writer

dissertation assistance purchase cialis pill cialis online buy

Enjoyed studying this, very good stuff, thanks.

I think this is among the so much vital info for me. And i’m happy reading your article. But wanna remark on few common issues, The site style is wonderful, the articles is really excellent : D. Just right job, cheers

Our community leaders need to read this, and look at developing some of your recommendations.

Howdy! I simply wish to give a huge thumbs up for the great information you have here on this post. I will be coming again to your weblog for extra soon.

imuran 25mg price order telmisartan 20mg without prescription telmisartan 80mg price

Cherished is likely to be what people say about your comments.

Great info! Keep post great articles.

This will be helpful for my family.

Regards for helping out, superb info.

bonjour I love Your Blog can not say I come here often but im liking what i c so far….

Thanks for discussing the issues and covering them in a well written format.

What i discover troublesome is to find a weblog that may capture me for a minute however your blog is different. Bravo.

Wish I’d thought of this. Am in the field, but I procrastinate alot and haven’t written as much as I’d like. Thanks.

Good points – – it will make a difference with my parents.

Muchos Gracias for your blog post.Really looking forward to read more. Much obliged.

This website has lots of really useful stuff on it. Thanks for informing me.

buy molnupiravir 200mg buy generic molnupiravir 200mg order lansoprazole 30mg for sale

Thanks-a-mundo for the blog article.Thanks Again. Really Great.

imuran order pantoprazole online phenazopyridine drug

This is definitely a wonderful webpage, thanks a lot..

You are my inspiration , I possess few web logs and very sporadically run out from to brand 🙁

Good points – – it will make a difference with my parents.

acetazolamide generic sildenafil citrate 50mg buy singulair 5mg for sale

Способ применения: расчешите брови и нанесите гель щеточкой в нужном направлении. Для выпрямления вьющихся волосков и фиксации особо жестких, нанесите несколько слоев геля, тщательно расчесывая волоски щеточкой. Когда мы думали об идеальном геле для бровей, то представляли мультифункциональное средство, которое придется по вкусу каждому, кто мечтает об идеальной укладке бровей, бонусом получая интенсивный уход за ними. По степени густоты и вязкости такой гель похож на плотную помадку для бровей, но окрашивает волоски в более насыщенный цвет. Для нанесения кремового геля лучше всего подходит скошенная кисть. Прежде чем состав успеет застыть, нужно прочесать волоски щеточкой для моделирования формы и закрепления в желаемом положении. Гель для бровей – это маст-хев в косметичке каждого визажиста, и на это есть сразу несколько причин: Брови у меня весьма…обильные)) и приводить их в порядок приходится регулярно. Этот гель очень мне помогает. Волосок к волоску весь день и каждый день. Отличнейшее средство. Рекомендую всем у кого бровки любят “показать характер” http://savetheworldforum.com/forum/profile/maurinemandalis/ Средство «Бимат» – совершенный аналог «Карепроста», «Latisse» и «Maxlash» и по ингредиентам, и по результативности. К тому же это средство имеет несколько безусловных достоинств: 1157 просмотров careprost.satu.kz • Коробочка косметического средства немного крупнее упаковки глазных капель. 3. Наносить Карепрост следует на самый край верхнего века, сразу над ресницами, аналогично нанесению «стрелки» при подводке глаз. Наносить препарат Карепрост на нижнее веко не нужно, достаточно увлажнения верхнего века. Чего нельзя делать Сохранить моё имя, email и адрес сайта в этом браузере для последующих моих комментариев. Акции и предложения от нас Применять препарат следует раз в сутки перед сном. Желательно, не менее чем за 30 минут, так как средству необходимо впитаться. Перед процедурой нужно тщательно вымыть руки. Из флакона следует выдавить 1 каплю вещества на аппликатор, или специальную кисть. На каждое веко необходимо наносить не больше 0.5 капли. Перед обработкой нужно снять всю косметику с глаз и бровей, а также контактные линзы.

This is really interesting, You’re a very skilled blogger. I have joined your feed and look forward to seeking more of your fantastic post. Also, I have shared your website in my social networks!

cialis 40mg pill buy deltasone deltasone 5mg pills

I came across an article that talks about the same thing but even more and when you go deeper.

Thank you a lot for sharing this with all folks you actually recognize what you’re speaking about! Bookmarked. Please additionally visit my site =). We can have a hyperlink trade contract among us!

Really enjoyed this article.Thanks Again. Awesome.

Woah this is just an insane amount of information, must of taken ages to compile so thanx so much for just sharing it with all of us. If your ever in any need of related information, just check out my own site!

buy azithromycin pills prednisolone 20mg pill prednisolone 40mg cheap

Very nice post. I just stumbled upon your blog and wanted to say that I’ve really enjoyed browsing your blog posts. In any case I’ll be subscribing to your rss feed and I hope you write again soon!

This will be helpful for my family.

doxycycline generic buy olumiant 2mg without prescription buy ivermectin cream

I think this is a real great blog. Really Great.

Thanks so much for the blog article.Much thanks again. Will read on…

I’ve been surfing online more than 3 hours today, yet I never found any interesting article like yours. It’s pretty worth enough for me. In my view, if all web owners and bloggers made good content as you did, the net will be much more useful than ever before.

Very neat blog post.Much thanks again. Will read on…

lopressor 100mg sale clomid 100mg us levitra 10mg drug

Thanks for discussing the issues and covering them in a well written format.

Just stumble upon your blog from from time to time. nice article

ventolin inhalator online buy purchase synthroid online buy aristocort 10mg without prescription

Thanks for another great post. Where else may anybody get that type of info in such an ideal way of writing? I have a presentation next week, and I’m at the search for such information.

How do I subscribe to your blog? Thanks for your help.

I really like your writing style, excellent info , thanks for putting up : D.

Just stumble upon your blog from from time to time. nice article

cheap zovirax 800mg buy aceon 4mg pill aceon 8mg cost

This content is accurate and true to the best of the author’s knowledge and does not substitute for diagnosis, prognosis, treatment, prescription, and or dietary advice from a licensed health professional. Drugs, supplements, and natural remedies may have dangerous side effects. If pregnant or nursing, consult with a qualified provider on an individual basis. Seek immediate help if you are experiencing a medical emergency. It is always wise to opt for an eyeliner that features a lightweight formula, especially if you have sensitive skin and want to use a hypoallergenic product. Natural eyeliners with a heavy pigment could also be a suitable choice because they hydrate your eyelids and prevent your eyes from becoming dry; We surveyed eyeliners regardless of price. We found that bad eyeliners aren’t necessarily cheap, nor are great eyeliners necessarily expensive. This is particularly true of liquid eyeliner—our two top picks cost less than $10. Based on our research, expensive eyeliners are far more likely to have fanbases than cheapies, which meant we had a lot of expensive eyeliner to acquire and then reject. https://plan2cost.com/community/profile/edwinreinhardt/ NYX is cruelty-free. NYX meets all the criteria to be a Logical Harmony Approved cruelty-free brand. There is no animal testing occurring anywhere on their products. They are not selling in any markets that require animal testing, and they do not sell in retail stores in China. PLASTIC FREE SKIN The Flower Beauty Bitten Lip Stains ($10) are a cruelty-free lip color that stain the lips to leave behind a long lasting tint. $21.00 Vitamin B-12 Supplement 1,000 mcg NYX is cruelty-free. NYX meets all the criteria to be a Logical Harmony Approved cruelty-free brand. There is no animal testing occurring anywhere on their products. They are not selling in any markets that require animal testing, and they do not sell in retail stores in China. While vegan products are great for the environment, they aren’t always cruelty-free — nor are cruelty-free products always vegan. “Vegan” means that the product’s formula doesn’t contain any animal-derived ingredients, while “cruelty-free” means that it was developed without animal testing.

whoah this weblog is wonderful i like reading your articles. Keep up the good paintings! You already know, many people are looking around for this information, you can help them greatly.

order fexofenadine 180mg for sale order astelin 10 ml order panadol generic

I think that may be an interesting element, it made me assume a bit. Thanks for sparking my considering cap. On occasion I get so much in a rut that I simply really feel like a record.

brand viagra uk

I would share your post with my sis.

Just wanna admit that this is extremely helpful, Thanks for taking your time to write this.

brand trileptal urso 300mg drug crestor over the counter

This has to be one of my favorite posts! And on top of thats its also very helpful topic for newbies. thank a lot for the information!

Greetings, have tried to subscribe to this websites rss feed but I am having a bit of a problem. Can anyone kindly tell me what to do?’

Thanks , I’ve recently been searching for info about this topic for ages and yours is the best I have discovered so far. But, what concerning the bottom line? Are you certain concerning the source?

Hey very cool site!! Man .. Beautiful .. Amazing .. I will bookmark your website and take the feeds also…I’m happy to find so many useful information here in the post, we need develop more strategies in this regard, thanks for sharing. . . . . .

Nice blog. Could someone with little experience do it, and add updates without messing it up? Good information on here, very informative.

Substantially, the post is really the best on this laudable topic. I concur with your conclusions and will eagerly watch forward to your future updates.Just saying thanx will not just be enough, for the wonderful lucidity in your writing.

Oh my goodness! an amazing article. Great work.

order zetia pills ezetimibe price buy baclofen 10mg generic

There are some serious financial ramifications here.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. If the download doesn’t start automatically, click here. The main idea behind Blackjack Instructor is to teach the user to identify the different ways in which he has to react when handed cards when playing Blackjack, thus being able to decide to hit or stay depending on the sum of the cards. Find every available Steam Key Stores for BlackJack Math and buy BlackJack Math. Compare them here to find the best prices, saving you time and money! You have a Blackjack and waifus here! Can you ask for more? There are attractive girls to play with, along with soothing music and lots of fun times. BLACKJACK and WAIFUS is an RPG, Simulation, and Casual game for PC published by KG AM in 2022. Addictive game! https://sethwofu764219.blogdal.com/17201419/easiest-online-poker-sites-for-australians Last on our list of the best Bitcoin casinos is FortuneJack. This exciting online casino provides you with numerous opportunities to gamble with your Bitcoin stash and watch it grow. You can choose between live casino games, sports bets, virtual dice, and many other casino games on the website. Playing crypto casino games is crucial in our test. We only choose casinos that have enticing casino games with high RTP percentages and provably fair outcomes. A casino must have top-tier slots and table games to be included in our list. No gambling experience is complete without the withdrawal of winnings. We always test cashout speeds and limits. Ideally, we look for crypto casinos with instant payouts and flexible withdrawal limits. The first Bitcoin casino to actually be licensed was Bitcasino.io, approved by the Curacao Gambling Licensing Authority in 2014. Since then, hundreds of other bitcoin casinos have joined its ranks, and many major online casinos have begun to accept bitcoin alongside mainstream payment methods.

A neighbor of mine encouraged me to take a look at your blog site couple weeks ago, given that we both love similar stuff and I will need to say I am quite impressed.

buy tizanidine 2mg generic buy cialis 20mg generic tadalafil 40mg usa

ทุกคนบางทีอาจจะเคยทราบหรือคุ้นชื่อกัน พอเหมาะพอควร สำหรับเกมส์ได้รับความนิยมน่าเล่นอย่าง slotxo แม้กระนั้นคุณจะรู้ไหมว่าเหม สล็อตออนไลน์ เกมนี้นั้น ได้มีเกิดมายาวนานแล้ว

I thought it was going to be some boring old post, but I’m glad I visited. I will post a link to this site on my blog. I am sure my visitors will find that very useful.

atorvastatin 20mg canada lisinopril buy online buy pregabalin 150mg for sale

When are you going to post again? You really entertain me!

Are grateful for this blog post, it’s tough to find good information and facts on the internet

Really enjoyed this blog post.Really thank you! Awesome.

desloratadine 5mg without prescription glimepiride 4mg cheap cost asacol

Great post. I was checking constantly this blog and I’m impressed! Very useful info specifically the last part 🙂 I care for such info much. I was looking for this certain information for a very long time. Thank you and good luck.

Do you offer workshops?

order irbesartan 300mg pill order nortriptyline 25 mg for sale buy pepcid 20mg sale

Hi there! I just wanted to ask if you ever have any trouble with hackers? My last blog (wordpress) was hacked and I ended up losing several weeks of hard work due to no back up. Do you have any solutions to protect against hackers?

viagra in canada

y8 เป็นผู้เผยแพร่เกมและก็ผู้พัฒนาเกม แพลตฟอร์ม Y8 เป็นโซเชียลเน็ตเวิร์กที่มีผู้เล่น 30 ล้านคนและก็กำลังเติบโต พีจี สล็อต ออนไลน์กับพวกเราได้ทุกที่ทุกๆเมื่อนิยมได้เงินจริง

There are no reviews yet. back to Microcosm Publishing homepage Probably the item we sell that will get us turfed off PayPal рџ‘ or our Instagram closed down. The Psilocybin Mushroom Bible details every step of the complex mushroom cultivation process, making it hands down the largest and most comprehensive book ever written on the subject. back to Microcosm Publishing homepage Join the SmokeDaddy mailing list for exclusive sale alerts! No spam. If you’ve mastered the art of growing mushrooms at home and have your growing method tuned in perfectly, or you’ve just got very good at foraging and have a reliable patch, you’ll have an endless stream of psilocybin-containing mushrooms. But where do you go from here? What’s the best method of extraction to minimize loss, and how can you stave off the dreaded nausea every time you dose? What’s the deal with microdosing, and how do you do it safely? And if you want to put on a three-course dosed dinner for a few of your best friends, what are the best dishes to cook? All these questions are answered, deliciously, in The Psilocybin Chef Cookbook. https://order-cannabis-online-7.bravejournal.net/post/2022/08/12/long-term-effects-for-marijuana You can possess and consume weed in Canada, subject to restrictions on amount and how it was purchased. However, it is still strictly prohibited to transport cannabis across the Canadian border – either into Canada from another country or from Canada into another country. The most poignant sign of the failure of the cannabis business, however, might be sitting in warehouses across the country. At its peak, last October, following the 2020 growing season, there was about 1.1 billion grams of harvested or processed cannabis held in storage: 95 percent of inventory has not been purchased by retailers or wholesalers, and much of it is “assumed to be largely unsaleable,” writes MJBizDaily’s Matt Lamers, whether because of degradation or excess supply. We have more pot in this country than we can possibly sell. Producers today are sitting on a massive, and predictable, oversupply that is slowly becoming worthless—and that’s going to cost a lot of companies a lot of money.

order tacrolimus 5mg online cheap tacrolimus for sale online tricor for sale online

slotxo introduces high-performance slot games, new updates, there are more than 200 pg slot games to choose from. Each game has different templates and high payout rates, don’t believe try the game.

gloperba generic inderal pills order generic clopidogrel 75mg

When we look at these issues, we know that they are the key ones for our time.

ramipril over the counter buy carvedilol without prescription coreg online order

buy oxybutynin 5mg pill order alendronate sale nitrofurantoin 100 mg for sale

I really liked your article post.Thanks Again.

Sweet blog! I found it while browsing on Yahoo News. Do you have any tips on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Thank you

Loving the info on this website , you have done outstanding job on the blog posts.

I encountered your site after doing a search for new contesting using Google, and decided to stick around and read more of your articles. Thanks for posting, I have your site bookmarked now.

I discovered your weblog site on google and verify just a few of your early posts. Proceed to maintain up the very good operate. I simply further up your RSS feed to my MSN News Reader.

Easily, the post is really the greatest on this laudable topic. I concur with your conclusions and will thirstily look forward to your future updates. Saying thank will not just be sufficient, for the wonderful c lucidity in your writing. I will instantly grab your rss feed to stay privy of any updates. Solid work and much success in your business enterprise!

Hi, do have a e-newsletter? In the event you don’t definately should get on that piece…this web site is pure gold!

My brother recommended I might like this web site. He was entirely right. This post actually made my day. You cann’t imagine simply how much time I had spent for this information! Thanks!

I really enjoy the post.Thanks Again. Fantastic.

ibuprofen tablet rocaltrol 0.25mg pill purchase calcitriol without prescription

Its like you read my mind! You seem to know a lot about this, like you wrote the book in it or something. I think that you can do with some pics to drive the message home a bit, but other than that, this is wonderful blog. A great read. I’ll certainly be back.

Hi there, just became aware of your blog through Google, and found that it’s truly informative. It’s important to cover these trends.

Wow, amazing blog layout! How long have you been blogging for? you made blogging look easy. The overall look of your site is great, as well as the content!

order bupropion 150 mg sale cheap zyban 150 mg sildenafil 50mg pills

tadacip 5mg price

You write Formidable articles, keep up good work.

purchase methotrexate cozaar price cozaar brand

Nice blog. Could someone with little experience do it, and add updates without messing it up? Good information on here, very informative.

Thanks for another great post. Where else may anybody get that type of info in such an ideal way of writing? I have a presentation next week, and I’m at the search for such information.

You are my inhalation , I possess few web logs and very sporadically run out from to brand 🙁

That’s some inspirational stuff. Never knew that opinions might be this varied. Thanks for all the enthusiasm to supply such helpful information here.

Beneficial Blog! I had been simply just debating that there are plenty of screwy results at this issue you now purely replaced my personal belief. Thank you an excellent write-up.

Hello there! This article could not be written much better! Looking through this post reminds me of my previous roommate! He always kept talking about this. I’ll forward this post to him. Fairly certain he’s going to have a great read. Many thanks for sharing!

I wish I could craft such articles as this. Thank you very much.

nexium 20mg cheap buy topiramate 200mg online cheap order generic imitrex 50mg

Zu den Spezialsymbolen gehört bei diesem Merkur Slot zum Beispiel der Torero. Der Stierkämpfer ist das Wild-Symbol, das unvollständige Gewinnlinien komplettiert. Ein weiteres besonders wichtiges Symbol ist der Stier, der die Freirunden starten kann. Weitere Symbole des Spiels sind die spanische Dame, die Gitarre, die Rose sowie der spanische Hut. Während den Freispielen wird der Torero auf den Walzen fixiert. So können sich deutlich mehr WILDs ansammeln, als im Basisspiel der Fall. In Deutschland leider kein online Angebot. Es gibt aktuell für Österreich ein paar Online Casinos wie Mr Green, die mit dem Hersteller Reel Time Gaming zusammen arbeiten und so die original Spiele mit Echtgeld anbieten. Leider heisst es für deutsche Spieler aktuell warten, wir halten euch auf dem Laufenden. https://abbysyarns.com/2022/community/profile/robertm09518128/ Bitte deaktivieren Sie sämtliche Hard- und Software-Komponenten, die in der Lage sind Teile unserer Website zu blockieren. Z.B. Browser-AddOns wie Adblocker oder auch netzwerktechnische Filter. Die einfachste Methode, zu seinem Traummesser oder einer M4A1-S zu kommen, sind die offiziellen Waffenkisten, die der Spieler mit etwas Glück nach einem Match erhält. Die Kiste allein bringt allerdings nichts. Es braucht einen Schlüssel, um sie zu öffnen. Dieser kostet 2.50 Franken. In den Kisten sind meist eine Handvoll Waffen-Skins. Mit etwas Glück erhält man ein Messer oder, je nach Kiste, einen Handschuh. Die Chance dafür liegt aber bei weniger als einem Prozent. Auf weiteren Drittanbieterseiten können die Spieler Skins kaufen, aber auch ihre eigenen Skins verkaufen – ein richtiger Markt eben. Die Skins gibt es in einer großen Preisspanne. Zum Verkauf stehen etwa laut Produktbeschreibung ein „fabrikneues“ Klappmesser für gut 131 US-Dollar oder ein „einsatzerprobtes“ und „mit lebhaften arktischen Farben lackiertes“ Sturmgewehr für gut 7 US-Dollar.

Thank you for your blog article.Thanks Again. Great.

Nice read, I just passed this onto a friend who was doing some research on that. And he just bought me lunch since I found it for him smile Therefore let me rephrase that: Thank you for lunch! “Do you want my one-word secret of happiness–it’s growth–mental, financial, you name it.” by Harold S. Geneen.

Hello there! I really enjoy reading your blog! If you keep making amazing posts like this I will come back every day to keep reading.

Makes sense to me.

I thought it was going to be some boring old post, but I’m glad I visited. I will post a link to this site on my blog. I am sure my visitors will find that very useful.

Thank you a lot for sharing this with all folks you actually recognize what you’re speaking about! Bookmarked. Please additionally visit my site =). We can have a hyperlink trade contract among us!

Took me time to read the material, but I truly loved the article. It turned out to be very useful to me.

order levofloxacin generic purchase levaquin without prescription zantac 150mg pill

Good site you have here.. It’s hard to find high-quality writing like yours these days. I truly appreciate individuals like you! Take care!!

It’s hard to find educated people in this particular topic, however, you seem like you know what you’re talking about! Thanks

order mobic 7.5mg for sale order meloxicam 7.5mg buy flomax 0.2mg online

I appreciate you sharing this article. Want more.

I really enjoy the post. Great.

There’s certainly a lot to find out about this issue. I really like all the points you made.

Unquestionably believe that which you said. Your favorite reason seemed to be on the net the easiest thing to be aware of. I say to you, I certainly get annoyed while people consider worries that they plainly don’t know about. You managed to hit the nail on the head. Will probably be back to get more. Thanks

Comments are closed.