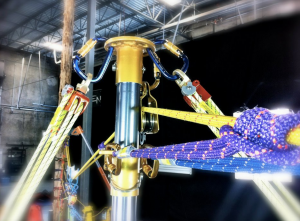

Generally, these beauties are considered pre-rigged pulley systems used mainly for hauling, but can be very important in lowering heavy loads as well. The advantage of these systems is in their rapid deployment, and straightforward operation without advanced levels of training or expertise. They are low maintenance and high yield work horses and have been around for many a year.

Generally, these beauties are considered pre-rigged pulley systems used mainly for hauling, but can be very important in lowering heavy loads as well. The advantage of these systems is in their rapid deployment, and straightforward operation without advanced levels of training or expertise. They are low maintenance and high yield work horses and have been around for many a year.

From old (and new) time mariners, to arborists, to rescuers, to the backyard working guy (or gal), jiggers have much to offer. An obvious application in industrial height safety, is lifting the weight of a fallen worker so that he can be transferred to a lowering rope. Arborists use many a jigger (fiddle blocks) for raising and pre-tensioning heavy loads. General riggers can apply these gems in hundreds of other manners (from pulling to maintaining).

Most of the time, double pulleys are teamed together to form a 4:1 mechanical advantage (depending on the line of pull, a 5:1 can also be accomplished). Efficiency is determined by the friction — or lack thereof — in the system (more on this in future newsletters).

Most of the time, double pulleys are teamed together to form a 4:1 mechanical advantage (depending on the line of pull, a 5:1 can also be accomplished). Efficiency is determined by the friction — or lack thereof — in the system (more on this in future newsletters).

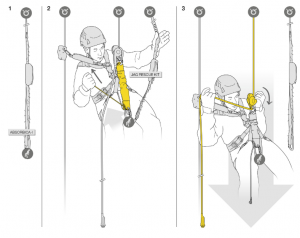

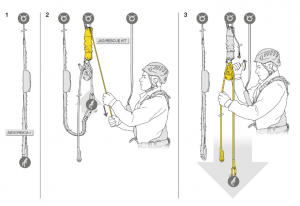

There is another very important factor to consider. All rescue pulley systems (and for that matter most non working pulley systems) must have a system which allows the rope to be pulled in while not allowing it to be released. This is called a progress capture or clutch system. Either prusiks or camming units can be applied. Your capture device will vary with circumstances and system, so choose wisely, because all systems are not created equal.

Jigger Uses

Jigger Uses

The usefulness of pulley systems extends well beyond simply the lifting of the rescue package:

- LIFTING the rescue package is what first comes to mind

- LOWERING under control (river rescue)

- SMALL JIGGERS(adjunct tasks, scoops, pick offs, etc.)

- LINEAR ANCHORS (between anchor points called pretensioned backties)

- GUYING of artificial high directionals at the edge

- APPLYING-HOLDING TENSION

- POSITIONING within space

Considerations

An optimum advantage of comprehending pulley systems is the fact it frees the rigger to assemble the system specific to the need. The following are key considerations before building a pulley system:

- Hauling area — What space is available for the hauling team?

- Throw length — What is the throw length? Is it sufficient?

- Haulers present (input) — How many haulers are available for the task to be undertaken?

- Load to be lifted (output) — The actual mass to be lifted: Climbing, rescue or extreme rescue load. Highline tensioning?

- Rope needs — How much rope is available for the pulley system you intend to construct?

- Equipment needs — How much equipment is available for the task you intend to undertake?

- Hauling area incline — Can you pull downhill? Wouldn’t you rather?

- Adaptability — Can you easily change the mechanical advantage?

- Resetting — Resetting can use valuable time & energy. Does the pulley system minimize this?

- Lowering ability — Can the pulley system lower easily under control? Also, will it respond quickly? River rescue? Live bait?

Simple, Compound, & Complex Pulley Systems

- SIMPLE: The rope is tied to either the load or the anchor and is run alternately through pulleys on the load or the anchor until the loose end finds itself in the grasp of the pullers.

- COMPOUND: A simple pulley system pulling on the end of a simple pulley system. (Each simple system is referred to as a component of the sum. May be more than two components)

- COMPLEX: A pulley system that is neither simple or compound.

Definitions

An established nomenclature serves to keep everyone on the same page in terms of what words are used for communication in any given system of specificity. Definitions of the words used within any nomenclature are key to insuring everyone using it is speaking the same language. Some of the terms in the nomenclature listed here may vary from terms you have used to describe the same principle.

- PULLEY: A small grooved wheel used with a rescue rope to change the direction and point of application of a pulling force and in combination (as in pulley system) to increase the applied force especially in a raising operation.

- PULLEY SYSTEM: An assemblage of rope and pulleys used to increase the force to the level required for the lifting or tightening to be undertaken.

- CHANGE OF DIRECTION: A pulley on the anchor closest to the haulers (cd or cod). A cd adds no mechanical advantage to the system.

- DIRECTIONAL: A Pulley or pulleys between the pulley system and the load to be raised (d). Both low and high directionals are common. Not to be confused with a change of direction.

- GANGED PULLEY SYSTEM: Any pulley system which is attached by a haul grab to a second main rope for the purpose of lifting or lowering a load.

- IN LINE PULLEY SYSTEM: A system where the rope lifting or lowering the load and pulley system are one and the same.

- THROW: The available distance between maximum pulley system extension and two-block (Note: Simple pulley systems have only one throw. Compound pulley systems have a minimum of two throws)

- HAUL FIELD: The available distance a hauler or haulers can run out or the space that they have to stand and pull

- HAUL GRAB: The rope grab closest to the load in any pulley system throw or compound pulley system component throw

- PIGGYBACKED: A compound pulley system with like same components. Example: (2:1) (2:1) (2:1)= 8:1 piggyback (3:1) (3:1)= 9:1 piggyback

- TWO BLOCK: The point at which the throw of any pulley system or pulley system component is collapsed. Also known as Chock-o-block

- RESET: The act of extending the pulley system throw out after “two block”

- RATCHET: The progress capture device allowing resetting of the pulley system after two block

- RATCHETMAN: A person who tends the ratchet for up or down on the pulley system

Some of the uses are as a pick off, travel restrict, adjustable directional, high directional guy-line, high angle attendant tether, high angle litter scoop, load release hitch and much more. Both Aztek pulleys have their own color coded Prusik and can be easily activated or deactivated. This means you can have the ratchet at either the top pulley or the bottom pulley. The special 3 on 2 Prusik cannot come off the rope, so the deactivated Prusik will stay ready to be used as soon as you need it. Complete systems use sewn Prusiks and a sewn eye on the main rope, which makes things neater and more compact than knots. You cannot appreciate how smooth and easy use of the Prusiks is until you experience it. Because the Prusik only sees a fraction of the total load in an MA system, they don’t get too tight and they are easy to release and very controllable.

coded Prusik and can be easily activated or deactivated. This means you can have the ratchet at either the top pulley or the bottom pulley. The special 3 on 2 Prusik cannot come off the rope, so the deactivated Prusik will stay ready to be used as soon as you need it. Complete systems use sewn Prusiks and a sewn eye on the main rope, which makes things neater and more compact than knots. You cannot appreciate how smooth and easy use of the Prusiks is until you experience it. Because the Prusik only sees a fraction of the total load in an MA system, they don’t get too tight and they are easy to release and very controllable.

This system grew out of extensive use and experimentation of small MA systems. It is light years ahead of anything else. If the world as we know it ends and you need an MA system to help you rebuild civilization, this is the one.

Peace on your days…

Lance

5 thoughts on “Jiggers Are Compact 4:1 Pulley Systems and are The Rigger’s Future”

466782 606443Yay google is my king assisted me to discover this outstanding internet site! . 227107

This is great article! Thank you 🙂

129568 979555I see something genuinely interesting about your web web site so I saved to bookmarks . 686891

771443 8309The Twitter application page will open. This is excellent if youve got several thousand followers, but as you get more and a lot more the usefulness of this tool is downgraded. 23946

825312 743309It is not that I want to duplicate your web site, but I actually like the style. Could you tell me which style are you employing? Or was it custom made? 963620

Comments are closed.