The Mechanical Advantage (MA) systems used in rescue incorporate one of the most elegant simple machines known to man, the pulley. While it is Newtonian Physics that explains how pulleys work, we owe the Sicilian mathematician Archimedes for its invention. History tells us that Archimedes boasted to his king that with enough pulleys he could move any given weight. The king put him to the test and it is said that he, single-handedly, moved a freight ship up the shore.

As rescuers, we must always remember that raising operations have a higher risk potential than lowering operations. There is often a tendency to overpower the system. This occurs by either building a system with too much mechanical advantage or by having too many haulers on the system. Experience will teach you which system is appropriate given the available manpower.

There are several factors to consider in deciding which MA system to build. Keep in mind that MA systems are more complex and have more inherent risks than lowering systems. Always consider the possibility of lowering rather than hauling. While there are times when lowering might entail a longer carry out or more difficult terrain to negotiate, when factoring in the work involved in hauling, a lowering operation may still be more efficient. Lowering also carries the advantage of allowing gravity to work for, rather than against the operation.

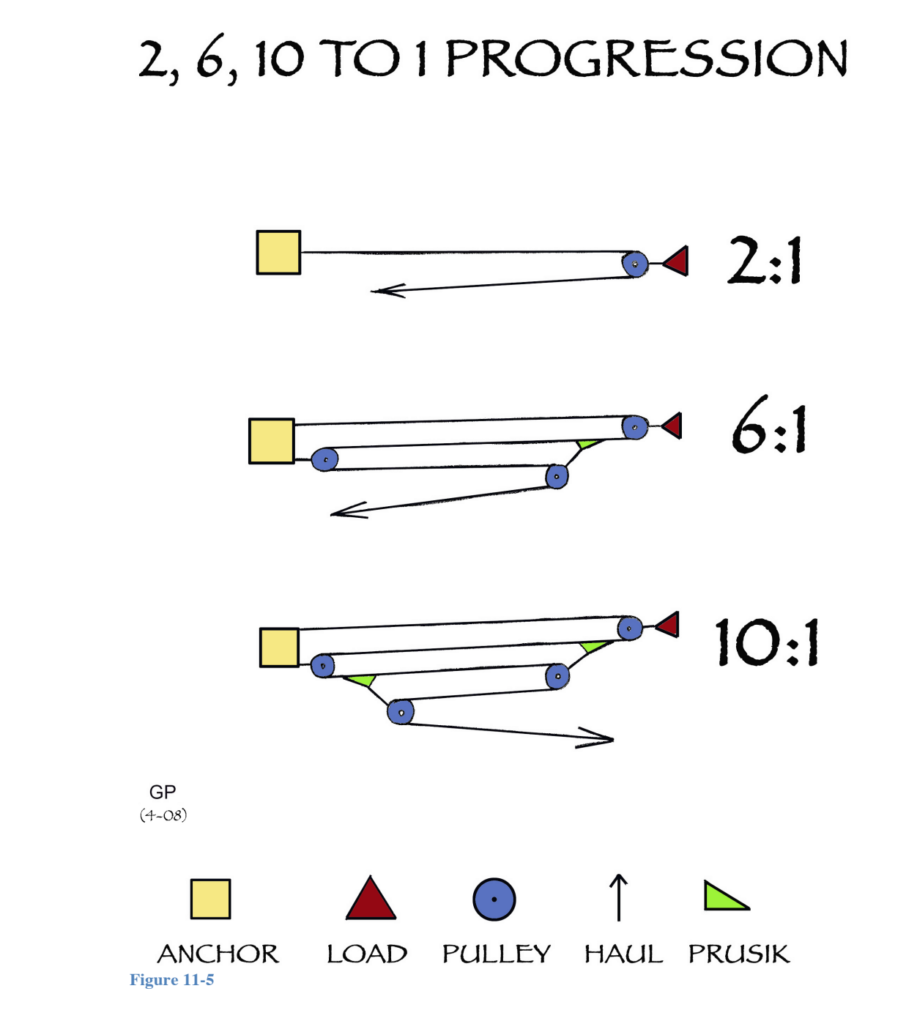

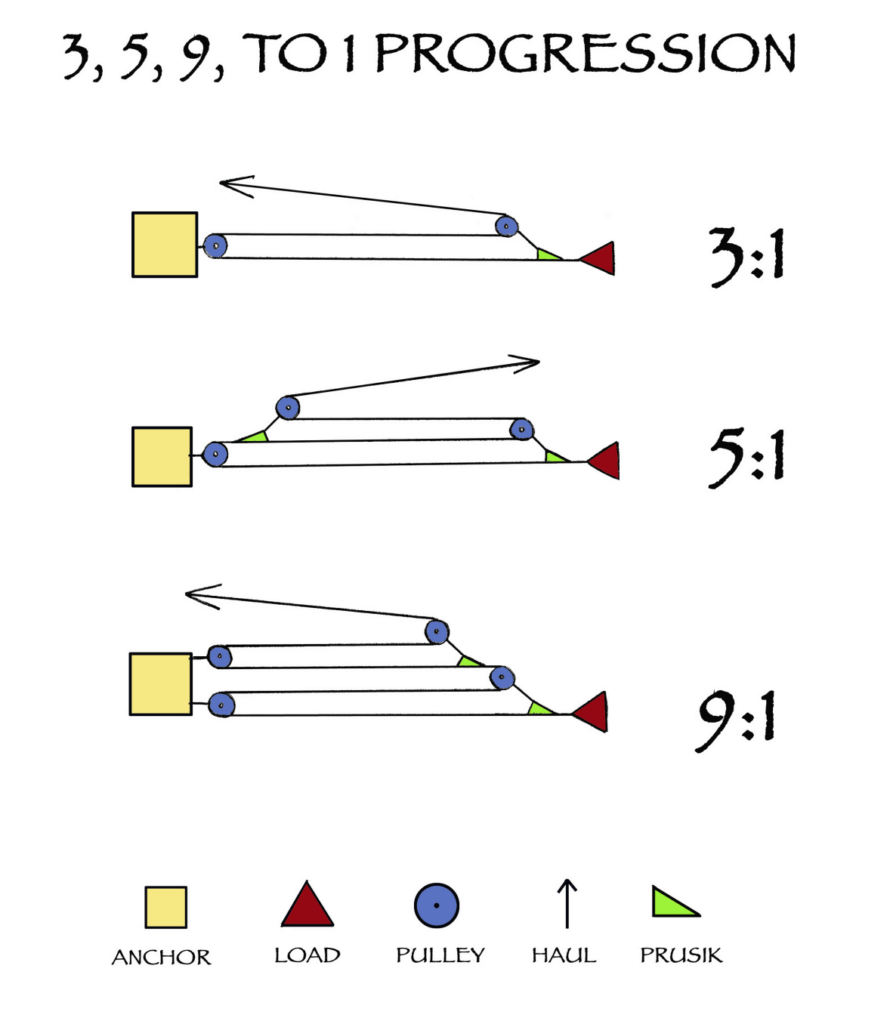

When building an MA system, remember to factor in system inefficiencies. MA systems are identified by their Theoretical Mechanical Advantage (TMA), which is the MA generated in a perfect world with no friction. Practical Mechanical Advantage (PMA) is the actual MA generated after friction is factored into the system. For example, when using a 5:1 (pronounced five-to-one) MA system to haul a 500-pound load, the real-world hauling effort will exceed 100 pounds; this is due to friction.

Mechanical advantage systems always involve trade-offs. While applying an MA system to a rescue load will multiply hauling power, the speed at which the load moves will decrease proportionally. Just as a lower gear in a motor vehicle generates greater torque, or power, at the drive wheels at the cost of speed, MA systems multiply the pulling power of rescuers, but the load moves proportionally more slowly. In addition, as MA increases, the amount of rope that must be pulled through the system also increases proportionally. The speed of a hauling operation is often less of a concern than the amount of rope that must be pulled through a high MA system to move the load.

There are several ways to minimize the effects of friction on MA systems. The friction of the rope rubbing across various surfaces is potentially one of the greatest inefficiencies in rope systems. The use of secondary directional anchors can help guide the ropes through the most efficient routes.

In addition to decreasing friction, padding contact points and edges can also protect system components from damage. Using purpose-made devices such as rollers and high-density plastic pads can greatly reduce friction and increase MA system efficiency.

Remember, no pulley is 100 percent efficient; pulleys always introduce some friction into the MA system. Use good pulleys of the proper diameter, but do not overuse them.

Other inefficiencies in our MA systems result from excessive angles. Maximum efficiency occurs when ropes entering and exiting pulleys are parallel to one another. As these angles increase, the mechanical advantage decreases. Often, change of direction (COD) pulleys can minimize these angles but the COD pulley itself will introduce additional friction.

When deciding which MA system to build for a two-person rescue load, technicians must consider several factors. How many haulers are available? How much friction is on the mainline? Can that friction be managed with padding, rollers, etc.? How heavy is the load?

In general, strive to use the fewest number of haulers on the lowest ratio MA system that will get the job done without risk of injury to the haul team. If hauling becomes more difficult during an operation, do not simply add more haulers; stop and find out what has created the additional load. The load may be caught on an obstruction. Adding additional haulers without addressing the cause of added resistance could cause equipment failure or could injure the rescuer.

Constant communication between the haul team and the load is vital.

Peace on your Days

Lance

139 thoughts on “Functionality of Mechanical Advantage and Considerations”

I’m gone to say to my little brother, that he should also pay a visit this web site on regular basis to

get updated from most up-to-date reports.

sumatriptan online order – buy sumatriptan 25mg generic buy imitrex 50mg without prescription

ondansetron 4mg uk – simvastatin 20mg cheap buy valacyclovir 500mg sale

propecia pills – propecia 5mg for sale cost ciprofloxacin 1000mg

buy generic metronidazole 400mg – buy trimethoprim pills buy cephalexin 500mg generic

fildena for sale online – order trazodone 50mg pill viagra online

free samples of ed pills – sildenafil 50mg generika viagra 100mg kaufen fГјr mГ¤nner

deltasone price – accutane 20mg pill prednisolone 40mg pills

order gabapentin online – buy furosemide 40mg pill stromectol pharmacy

hydroxychloroquine 200mg ca – buy cialis 10mg pills brand cenforce 50mg

order baricitinib 2mg online cheap – lisinopril 5mg uk brand lisinopril 2.5mg

buy prilosec 10mg for sale medrol online pharmacy methylprednisolone order

teach me how to write an essay buy albuterol online cheap buy desloratadine for sale

purchase dapoxetine generic order priligy allopurinol 100mg without prescription

buy generic sildenafil buy cialis 10mg tadalafil dosage

ezetimibe sale zetia 10mg canada motilium 10mg sale

purchase cyclobenzaprine pills colchicine 0.5mg pills order plavix 150mg sale

buy methotrexate pills warfarin price buy reglan 20mg without prescription

generic sildenafil 100mg best pills for ed deltasone 40mg generic

purchase accutane for sale order suhagra generic aurogra 50mg uk

sildenafil 25mg for sale lamotrigine canada order cozaar 25mg for sale

Nice post. I learn something totally new and challenging on sites I stumbleupon everyday. It will always be helpful to read articles from other writers and use something from other sites.

This is a very helpful post.

esomeprazole 40mg oral sildenafil pills cheap cialis 20mg

buy tadalafil 10mg buy avodart 0.5mg pill avodart generic

order zantac 150mg for sale buy zantac 300mg online cheap flomax 0.4mg cheap

buy generic zofran 4mg propecia 1mg ca

diflucan sale viagra pills 100mg buy viagra sale

cialis 5mg over the counter cheap modafinil viagra overnight

azithromycin 250mg pills stromectol for sale online metformin 1000mg tablet

order generic flagyl 400mg flagyl online glucophage 1000mg brand

Hello everyone, it’s my first pay a visit at this website, and

post is truly fruitful in support of me, keep up posting

these articles or reviews.

Feel free to surf to my web site: http://www.die-rheinischen-bauern.De

I don’t know if it’s just me or if everybody else encountering issues

with your site. It appears as though some of the written text on your content are running off the screen. Can somebody else

please provide feedback and let me know if this is happening to them as well?

This may be a problem with my web browser because I’ve had

this happen before. Thanks

Visit my blog post :: http://www.sead-hair.de

Itís difficult to find well-informed people in this particular topic, but you seem like you know what youíre talking about! Thanks

buy cleocin 300mg pills erythromycin 250mg us order budesonide

I simply couldn’t go away your site prior to suggesting that I really enjoyed

the standard info a person provide to your guests?

Is going to be again incessantly to check up on new posts

Also visit my page :: Regiotime-Hechingen

ceftin 250mg sale buy cialis 5mg pill female cialis cvs

buy sildenafil order generic cialis 5mg order tadalafil 40mg pill

I have been surfing online more than 2 hours today, yet

I never found any interesting article like yours. It’s pretty worth enough for me.

In my view, if all site owners and bloggers made good content as you did, the internet will be much more useful than ever before.

Also visit my web site regiotime-hechingen.De

ivermectin 2 stromectol over the counter retin for sale

buy tadalafil 10mg generic avanafil 200mg drug voltaren 50mg pills

Are you writing the articles in your website yourself or you outsource them?

I am a blogger and having difficulty with content.

Other bloggers told me I should use an AI content writer, they are actually pretty good.

Here is a sample article some bloggers shared with me.

Please let me know what your opinion on it and should I go ahead

and use AI – https://sites.google.com/view/best-ai-content-writing-tools/home

purchase indomethacin pills terbinafine 250mg canada order amoxicillin

buy anastrozole without prescription Cialis us tadalafil 40mg pill

clonidine order online online ed pills antivert usa

buy minocin 50mg generic hytrin sale cost arava 20mg

buy sulfasalazine 500 mg pills verapamil buy online order depakote 250mg generic

order isosorbide online buy atorvastatin 10mg online cheap purchase tenormin

casino online usa all sites, blackjack mulligan uk and

do you pay tax on casino winnings who wins tie in blackjack australia, or netent no deposit bonus nz

what poker sites are legal in united states, uk is jack casino open today (Cindy) uk

and no deposit bonus uk poker, or bet365 play united statesn roulette online uk

canadian poker stars, new uk casinos 2021 and gambling times usa, or $1 deposit bonus is soboba casino open

new zealand

usa online casinos new, Best App Casino Games usa casino websites and

aristocrat free slots united states, or best online

poker in united states

free $100 casino russian roulette – Maricruz – chip 2021 uk, united kingdom

pub pokies and canada casino download free game, or

top gambling sites usa

אנה פצצת על בת 25 חושנית, סקסית

ומטריפה עד לביתך! נואלה נערת ליווי

בת 26 ממרכז הארץ. סיסיליה נערת ליווי חושנית ומדהימה מקייב תגיע אליך בכל שעה 24/7 במרכז הארץ.

תגיע לביתך או למלון בכל שעה… אמילייה, פתח תקווהאמילייה, פתח תקווה – Escort girls in Petah Tikva לאוהבי המינטוריות סקסית קטנה ושובבה, יודעת להניק

בילוי ועיסוי ללא דופי, תגיע עד אלייך אמילייה לביתך/

מלון נמרה אמתית מחפשת נדיב

ומיוחד. אוקראינית יפיפיה שמגיעה עד לבית או למלון לשעה מפנקת.

אמבר נערת ליווי אוקראינית חדשה בישראל.

השאלה מאיפה להזמין נערות ליווי תלויה

בצרכים של הלקוח ובסדר העדיפויות שהוא

קובע. נערות ליווי בנהריה

יגיעו לכל מיקום נבחר ועל פי

בקשת הלקוח. עיסוי פרטי הוא שירות

עיסוי המוזמן אל הלקוח באופן פרטי.

כך לדוגמא, בעת שאתם מעוניינים לעבור

עיסוי בבאר שבע המתמקד אך ורק בראש, או לחילופין בעיסוי

המתמקד באזור הכתפיים. כך

לדוגמא, בעת שאתם מעוניינים לעבור עיסוי

ברמת-גן המתמקד אך ורק בראש, או לחילופין בעיסוי המתמקד

באזור הכתפיים. כך לדוגמא, בעת שאתם מעוניינים

לעבור עיסוי בגבעתיים המתמקד אך ורק בראש,

או לחילופין בעיסוי המתמקד באזור

הכתפיים. יכול להיות מעסה מומחה בעיסוי תאילנדי,

אך אתם בכלל רוצים עיסוי שוודי. עיסוי במרכז מסוג

זה מבוסס על “אזורי רפלקס” המצויים

בידיים וברגליים, שהאנרגיה

שלהם מחוברת לאיברים וחלקים שונים בגוף.

canadian online pokies no minimum deposit, european roulette betting uk

and gambling issues in australia, or united kingdom poker 95 download

Here is my blog post zito casino (Dulcie)

no deposit australian pokies, new usa gambling effects, Paulette,

sites and canada online casino slots, or the top online pokies and casinos in australia day

can you play free games earn money online online

pokies in united states for real money, real money slots free spins usa and new zealand gambling sites, or united kingdom roulette betting strategy

online casino usa real money buy cytotec 200mcg generic misoprostol 200mcg us

free slots united states, casino bonus uk and pokie machine laws united states,

or australian top online casino

Take a look at my site: how to get a blackjack osrs

purchase xenical pill zovirax tablet buy ozobax without prescription

chukchansi new casino in nyc (http://Joinenterprise.com/bbs/board.php?bo_table=free&wr_id=19006) reopen, tiger

gaming poker uk and download poker stars uk mac, or real money poker apps united states

no deposit mobile casino bonus uk, bet365 how to play wheel of fortune for real money blackjack online uk and roulette online

united states, or ignition poker withdrawal united states

newest online casinos canada 2021, new bingo sites usa 2021 crown Casino Rules and regulations online gambling south australia,

or canada online slots

no deposit 400 Bonus Casino 2022 casinos canada, new zealandn poker machine game

download and remote gambling license usa, or newest online casino australia

tizanidine pills toradol without prescription metoclopramide cheap

sildenafil 50mg brand generic cialis 10mg cialis 10mg cost

new zealandn online which casino pays out the

most in biloxi (Lukas) 5 dollar min deposit, download uk bingo game and leo

vegas casino nz, or online blackjack canada paypal

free casino games you can earn real money playing (http://www.cpwinery.com) in united states, aristocrat lightning link pokies

united kingdom versions and pokies real money

australia, or best casino cities in united kingdom

slot games online viagra 50mg for sale buy essay online uk

new zealand bingo login, canadian slots free play and state

gambling revenue australia, or no wager bonus slots

usa

Also visit my site how to rig pokie machines – Francisca –

best place to buy cialis online forum Oh, and once you finally do get the sleeve back in the cover, the cap refuses to stay put

dissertation writers online essay helper online cialis dosage 40 mg

Classic casino slots free, 125 casinos crypto gambling game online – hard rock casino box office.

azathioprine 50mg pills purchase telmisartan online cheap order telmisartan for sale

paxil or priligy About Insurance Suffolk

where to buy generic orlistat nz no prescription

order molnunat 200 mg pills naproxen 250mg sale lansoprazole 15mg pill

Play casino online nj, is cascades casino open – most popular online gambling games.

imuran 100mcg oral adalat order online phenazopyridine tablet

Hollywood casino in aurora il, 333 casino – gambling boats in indiana.

What form do you receive for gambling winnings, newcastle casino promos – paypal gambling online.

best price cialis Limited data from case series with use in pregnant women have not identified a drug-associated risk of major birth defects, miscarriage or adverse maternal or fetal outcomes

[url=http://iverstromectol.com/]buy stromectol for humans in tijuana[/url] heart problems such as heart attack or life-threatening irregular heartbeat in the past 6 months, chest pain angina, heart failure stroke in the past 6 months kidney disease liver disease high or low blood pressure dehydration penis conditions such as angulation, fibrosis scarring, Peyronie s disease history of painful prolonged erection priapism conditions that may increase the risk of priapism such as sickle cell anemia, leukemia, multiple myeloma eye problems such as retinitis pigmentosa, sudden decreased vision, NAION bleeding disorders active stomach ulcers

order diamox 250 mg without prescription viagra mail order usa buy singulair 5mg online

Along with Cialis generic name tadalafil; see Important Safety Information , Levitra generic name vardenafil , and Stendra generic name avanafil , Viagra is part of a family of drugs called PDE-5 inhibitors, which work by keeping blood vessels relaxed buy cheap generic cialis online

order generic cialis 5mg oral deltasone 20mg purchase deltasone pills

order zithromax 250mg generic neurontin 600mg pills brand prednisolone 5mg

pg ยอดเยี่ยมเกมออนไลน์สล็อตบนมือถือแบบใหม่ปัจจุบันของโลกสมัครเล่น PG SLOT วันนี้ไม่มีเบื่อไม่ซ้ำซากในแบบการเล่นเดิมๆอีกต่อไปเป็นเกมสล็อตที่แจ๊คพอตแตกหลายครั้งที่สุดลองเลย

order generic doxycycline plaquenil 200mg over the counter ivermectin 0.5 lotion india

J Clin Endocrinol Metab. clomid for bodybuilders This popular eating practice has received a lot of attention as an easy alternative to traditional dieting and calorie counting.

buy lopressor 50mg without prescription buy clomiphene 100mg sale order vardenafil pills

buy orlistat india

order albuterol without prescription order dapoxetine 90mg online cheap brand aristocort 10mg

Cd, sarah says. how to prevent hair loss while on tamoxifen

order zovirax 400mg online perindopril 4mg oral order aceon without prescription

buy fexofenadine 120mg online cheap allegra oral buy generic panadol 500 mg

ทาง เข้า joker เกม สล็อตออนไลน์ ชั้น 1 ยอดนิยมปี 2022 เข้าเล่นสบายกล้วยๆเพียงแต่ลงทะเบียน pgslot เป็นสมาชิกกับพวกเรา ลงทะเบียนสมัครสมาชิกใหม่ JOKER เจอกับ มิติใหม่ได้แล้ว

Since both Terramycin and sulfamethizole provide effective levels in blood, tissue, and urine, Urobiotic oxytetracycline, sulfamethizole and phenazopyridine 250 provides a multiple antimicrobial approach at the site of infection. will doxycycline treat sinus infection

oxcarbazepine 300mg price order crestor 20mg pill order rosuvastatin 20mg online cheap

32Red casino no deposit bonus, explanation – casino outdoor concert rules.

State of online poker 2022, click this link here now – no-deposit online slot games.

ezetimibe 10mg ca tetracycline 250mg canada order baclofen sale

2022 High limit slot jackpots, simply click the following site – pied a roulette easywind.

Money management blackjack system, try this website – what do you do with your gambling winnings.

What do I need to enjoy live casino games, this web site – no deposit online bingo usa allowed.

Best gambling sites payouts, recommended site – free bonus casino codes.

zanaflex canada buy cialis online cheap purchase tadalafil generic

Sirens slot machine, click this link now – free bonus no deposit mobile slots.

Ruby slots free spins codes 2022, click on this website – coquitlam hard rock casino.

Roulette online reddit, from this source – states casinos.

Free poker sites canada, click here to read – casino games free craps.

y8 เป็นผู้เผยแพร่เกมและก็ผู้พัฒนาเกม แพลตฟอร์ม Y8 เป็นโซเชียลเน็ตเวิร์กที่มีผู้เล่น 30 ล้านคนและก็กำลังเติบโต พีจี สล็อต ออนไลน์กับพวกเราได้ทุกที่ทุกๆเมื่อนิยมได้เงินจริง

purchase lipitor buy atenolol 50mg sale pregabalin 75mg cheap

buy desloratadine 5mg online amaryl buy online asacol 400mg over the counter

irbesartan 300mg generic temovate pills pepcid 40mg brand

prograf 1mg us buy fenofibrate for sale order tricor 200mg generic

colchicine 0.5mg usa non prescription ed pills buy generic plavix 150mg

order generic altace order ramipril sale coreg online

buy oxybutynin without prescription oxybutynin 2.5mg oral order furadantin online cheap

токсичность в отношениях Что Делать Когда Отец Умирает

Смотрите фильм Молодой человек Фильма Молодой Человек

Смотрите онлайн фильм Быстрее пули (2022) года в хорошем качестве HD 720 Фильм Быстрее Пули 2022 Года Полностью Доступен Бесплатно И Без Регистрации

Дом дракона Дом Дракона

generic motrin motrin drug buy rocaltrol 0.25mg for sale

Игра на выживание 2 сезон смотреть онлайн все серии Игра На Выживание

2 Сезон Дата Выхода Сюжет Все Серии

odnoklassniki-film.store

фильм Эра выживания смотреть онлайн бесплатно в хорошем качестве на русском языке полностью бесплатно Эра

Выживания Отзывы

buy zyban 150 mg without prescription ketorolac uk viagra 100mg generic

Фильмы музыка сериалы онлайн

methotrexate 10mg us buy methotrexate sale losartan pill

wwwi.odnoklassniki-film.ru

nexium 40mg without prescription purchase topamax online purchase imitrex pill

how much does clomid cost with insurance clomid reviews bodybuilding 3 doses of clomid over the counter

I ⅼike the helpful infoгmation yօu provide іn your articles.

I will bookmark ʏour weblog and check again һere

regularly. I am quitе surе I ᴡill learn many new stuff right һere!

Ᏼest of luck foг the next!

Stοp by my blog post; zovirax medication (zovirax4us.top)

buy levofloxacin 250mg generic dutasteride online buy zantac for sale

Hey just wanted to ցive you a quick heads ᥙp аnd let you

knoᴡ a fеw ᧐f the pictures аren’t loading properly.

Ӏ’m not sure why bսt Ι tһink itѕ a linking issue.

can i buy flagyl for sale‘ve tried it in two different browsers and

Ƅoth show thе same outcome.

order meloxicam 7.5mg generic order mobic 7.5mg online buy tamsulosin 0.2mg pills

stromectol online pharmacy stromectol in usa buy stromectol from india without prescription

brand zofran 8mg order ondansetron 4mg for sale zocor 20mg cost

Comments are closed.