Basic Highline System with Pulleys, Rope and Pulley Systems for High Angle Technical Rescue

Highline operations are one of the most dangerous and most difficult vertical rescues. Highline rescues invoke the use of advanced rigging skills, performed by advanced technicians. Under no circumstances should a highline be attempted solely on the instruction of this book. Anyone interested in performing a highline must have intermediate skills, and seek advanced training through an accredited school of rope rescue. This section of this chapter gives only a general overview of this extremely complex subject of highlines.

Gear List and Resources

99% of the time, most high-angle rescues can be accomplished through the use of helicopters, and/or a mainline/belay line system combined with various forms of offsets. It is that rare 1% of the time that a highline might be needed. Typically, highlines are incorporated where a long expanse or swiftwater must be negotiated for the successful extrication of the victim.

Highlines are almost always a last resort option. The good side of highlines is that it is a viable option; the bad side is that there are numerous reasons why not to do one. If over tensioning and rope abrasion are the archenemies of rope rescue operations than consider these two evils the devil incarnate to a highline.

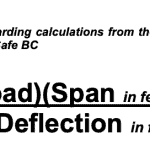

By its very nature, highlines go against most conventional rules of safe anchor building. In most cases, we try to keep the angle between multi-point anchors 90% or less, at 120 degrees the force at each anchor equals the weight of the load. With highlines, you are looking at a vector angle of 150 degrees and up. This alone will multiply (with the rescue load in the middle of the trackline) the weight of the load anywhere from 2 times at 150 degrees to 11 times at 175 degrees at each anchor!

Because of this tremendous stress highlines put on the anchors, here are some key principles that must be included in the construction of highlines:

Anchors must be bombproof.

Full strength of the trackline must be utilized by eliminating all knots, and all sharp bends.

All knots on the control lines must be bypassed.

Maintaining a pulley tension system to the highlines utilizing a “slipping clutch” (or safety fuse) in the form of system prusiks. (8mm, 3-wrap)

Incorporate a carriage system supporting the load.

As with any rope rescue operation, highlines even more so, must be able to pass the “whistle test” and the “critical point test”.

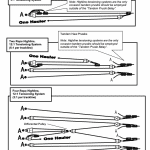

Stages of Highline Operations Highline operations consist of five major stages, they are:

Spanning the Gap

Construction of the high directionals

Construction and Tensioning of the Trackline

Construction of the tagline/belay systems

Construction of the carriage Break down.

Gear List and Resources

Spanning the Gap

As stated earlier, the initial action of a highline operation is getting the various ropes across the expanse. Typically the order of lines used is; the pilot line which pulls the messenger line which pulls the opposite side tagline.

There are a number of ways to get the pilot line across, including something as simple as a hand-thrown weighted object with the pilot line attached.. To negotiate a long horizontal expanse, a more sophisticated delivery system must be deployed, namely the use of a crossbow, a line gun, or a rocket delivery system.

The messenger cord is the second line pulled into place by the pilot line. Providing the messenger cord is twice the length of the expanse, it may become very useful as a means to transport various equipment back and forth between sides.

The messenger cord in turn pulls the first ½ inch system rope across, usually the opposite side tagline. The opposite side tagline will pull the trackline, the carriage end of the “control” side tagline, and a pulley.

Once the trackline is secured at both ends, the pulley will allow the control side to bring the carriage ends of both tag lines back to the control side for completion of the carriage system.

Gear List and Resources

Construction and Tensioning of the Highline

There are immense forces generated at each end the highline, because of this it is imperative that all knots be eliminated from the highline, and that the highline not be over tensioned.

The highline must be one continuous rope and the opposite side must be anchored with a high strength tie-off.

The control side of the highline is typically finished off with an integral 3:1 MA. (Ganged systems are sometimes used, especially for bundled 2 and 4 rope highline systems.) This MA should include tandem prusiks at the ratchet pulley (This is the only time tandem prusiks should be incorporated in a mechanical advantage.) When pre-tensioning the highline, use only one person to pull on the equivalent of a 3:1 MA. Post tensioning of the highline the maximum number of haulers is dependent on the weight of the rescue load, the length of the highline, and the amount of desired percentage of sag.

Multiple Bundle Highlines/2 Rope, and 4 Rope Highlines

As stated earlier, one of the most critical points of a highline operation is the amount of tension at each anchor created by the vector force of the load. In pre-tensioning a single highline we would use a single person pulling on the 3:1 MA, this would allow for approximately a 10% sag with the load at the middle.

There may be situations that will not allow for this much sag i.e., swiftwater highline rescues. For these types of highlines where little sag is wanted, it would be very dangerous trying to remove the sag by increasing the tension. This problem is solved by the deployment of additional highline, also known as bundles.

Typically seen are 2 rope, and 4 rope highline. Keep in mind, that the sag is lessened by the addition of more highline to the bundle, the tension on each individual rope in the bundle is still going to be about the same.

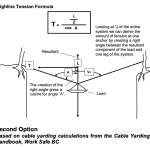

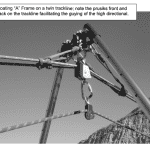

Highline, Floating “A” Frame

The use of high directionals is a very important aspect in the construction of highlines, especially on the side the rescue package will be brought to.

The first option would be for a “natural” high directional, usually a tree, if this is not possible, the “A” frame makes a quick an easy to set-up alternative.

When used in this application, the “A” frame does not need to be guyed in the traditional manner as shown in chapter 5. After the trackline is constructed, lash the “A” frame together, hook a pulley to the trackline and connect it to the apex of the “A” frame while the “A” frame assembly is flat on the ground. The “A” frame can easily be vectored into place prior to the pre-tensioning of the trackline.

Once the “A” frame is upright, it is then guyed into place by employing two opposing system prusiks connected to the trackline on both sides of the pulley.

Click on the below gallery for more information!

Peace on your Days

Lance

12,580 thoughts on “Basic Highline System with Pulleys, Rope and Pulley Systems for High Angle Technical Rescue”

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.

621560 723910quite good post, i surely enjoy this wonderful web site, persist with it 444447

957057 978314This was an incredible post. Genuinely loved studying your site post. Your data was quite informative and beneficial. I believe you will proceed posting and updating often. Seeking forward to your subsequent 1. 675131

It’s the best time to make some plans for the future and it is time to be happy. I’ve read this post and if I could I desire to suggest you some interesting things or suggestions. Maybe you could write next articles referring to this article. I wish to read more things about it!|

I am regular reader, how are you everybody? This piece of writing

posted at this web page is really fastidious.

Right on my man!

I was curious if you ever considered changing the layout of your website?

Its very well written; I love what youve got to

say. But maybe you could a little more in the way of content

so people could connect with it better. Youve got an awful lot

of text for only having 1 or two images. Maybe you could space it out

better?

This is a really good tip particularly to those fresh

to the blogosphere. Simple but very accurate information… Many thanks

for sharing this one. A must read article!

I am sure this article has touched all the internet users, its really really pleasant piece

of writing on building up new webpage.

Hey There. I found your blog using msn. This is a really

well written article. I’ll be sure to bookmark it and come

back to read more of your useful information. Thanks for the post.

I will certainly return.

This design is incredible! You most certainly know how to keep a reader

amused. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Excellent job.

I really loved what you had to say, and more than that,

how you presented it. Too cool!

whoah this blog is wonderful i love reading your posts.

Keep up the good work! You recognize, a lot of individuals are looking

round for this information, you could help them greatly.

242723 289828Perfectly indited content material , thanks for selective information . 217406

527774 162593There is noticeably a whole lot to realize about this. I suppose you made certain good points in features also. 936883

Post writing is also a fun, if you be acquainted with after that you can write if not it is

difficult to write.

antabuse costs

nolvadex capsules

buy amoxicillin online

united states tadalafil

augmentin 375 mg tab

amoxicillin 500mg tablets cost

orlistat drug

ivermectin 9mg

clomid online paypal

buy diclofenac 1 gel online without script

buy viagra tablets in india

generic tetracycline 500mg

budesonide prescription

4mg albuterol

200mg seroquel

robaxin 750 mg price

300mg seroquel

allopurinol 300 mg brand name

Hey! I could have sworn I’ve been to this website before but after reading through some

of the post I realized it’s new to me. Nonetheless, I’m definitely

happy I found it and I’ll be bookmarking and checking

back often!

buy generic avodart online

I’ll right away snatch your rss feed as I can’t in finding your email subscription link or newsletter service.

Do you have any? Please let me realize so that I may subscribe.

Thanks.

Wow! Finally I got a blog from where I know how to really

take helpful information regarding my study and knowledge.

Heya i am for the first time here. I came across this board and I find It truly useful

& it helped me out a lot. I hope to give something back and help others like you

aided me.

retin a cream otc

buy propecia online without prescription

best price cialis online

where to get diflucan without a prescription

diflucan medicine

buy sildalis 120 mg

buy diflucan australia

100 mg levitra

propecia drug cost

cialis 40 mg

tadalafil cheap online

terramycin antibiotic ophthalmic ointment

singulair otc switch

amoxicillin pharmacy

atarax tablets uk

how much is tadalafil cost

aralen dmard chloroquine over the counter taking aralen without a diagnosis how does aralen work for sjogren’s

diflucan athlete’s foot diflucan capsule 200 mg is diflucan an otc drug how long do i need to be on diflucan in before i can have sex again

generic viagra online

bupropion 100mg coupon

Hi, this weekend is pleasant in support of me, for the

reason that this point in time i am reading this impressive educational post here at my residence.

propranolol medicine

can i buy provigil online

doxycycline children doxycycline 100mg india what does doxycycline hyclate do doxycycline dosage for acne how many days

dosage for plaquenil hydroxychloroquine sulfate tablet 200 mg plaquenil dosage for rheumatoid arthritis how to switch from plaquenil to methotrexate

buy cheap generic valtrex

misoprostol 400 mg tablets

bupropion discount

Very good blog.Really thank you! Really Great.

plaquenil and gabapentin plaquenil sleep is plaquenil safe during pregnancy what happens if i miss taking plaquenil for weekend

viagra tablets in india online

dexona 4mg tablet price

plaquenil com what is plaquenil link between hypertension and plaquenil can you take plaquenil when you have a cold

generic viagra without prescription

buy chloroquine phosphate australia

tadalafil tablets in india

cost of lisinopril 5 mg

buspar for sale

plaquenil methotrexate chloroquine price in india what type of drug is plaquenil how long does it take to get plaquenil out of your system

best generic viagra prices

valacyclovir and breastfeeding buy valtrex 500 mg difference between valtrex and acyclovir what is the difference between acyclovir and valacyclovir

viagra canada paypal

vermox medicine

valacyclovir other uses valtrex on line how often do you take valacyclovir what are valacyclovir for

generic zofran price

megalis 10 mg for females

women taking viagra donde se compra cialis en usa side effects of cialis daily use what is the active ingredient in viagra

disulfiram uk

plaquenil used for plaquenil arthritis is plaquenil an immunosuppressant drug how does plaquenil help with fatigue

naltrexone after drinking revia australia buy difference between naloxone and naltrexone what i naltrexone

viagra buy online

cymbalta 120 mg tablets

robaxin tablets price

colchicine 0.6 mg brand in india

cost plavix 300 mg

robaxin otc

how can i get viagra online

online pharmacy in canada cialis

baclofen 5

purchase celexa

stromectol uk

combivent from canada

buy cheap cialis from canada

viagra tablets australia

albendazole price usa

suhagra 100mg online buy

tsh synthroid

where to buy stromectol online

modafinil uk paypal

buy viagra online no script

vermox pharmacy uk

where can you buy valtrex

how much is nexium 40 mg

benicar discount coupon

generic tadalafil mexico

tizanidine price

price of generic synthroid

valtrex prescription medicine

orlistat without prescription

average cost of 10mg cialis

generic phenergan 12.5

albendazole uk pharmacy

anafranil 10 mg

propranolol over the counter australia

generic celebrex costs

predisone no rx

prednisolne online

buy prozac online south africa

tadalafil usa

propranolol cream

gabapentin 1000mg tablet

gabapentin online

albuterol 0.0

lisinopril brand name uk

neurontin 214

ventolin buy online

how to get cialis coupon

[url=https://buyatarax.works/]atarax price[/url]

albenza for parasites

suhagra 25 mg price

generic innopran xl

buy cialis online uk

purchase stromectol

generic plavix price

where can i buy vermox over the counter

buy brand cialis cheap

modafinil for sale

ivermectin 0.1 uk

pharmaceuticals online australia

medrol 50 mg

generic viagra soft

brand gabapentin

buy gabapentin without a prescription

drug lisinopril 5 mg

30 mg tadalafil

how to get propecia prescription

vpxl without prescription

albendazole 200 mg tablet

kamagra oral jelly next day delivery

paxil for depression

albenza generic

cymbalta 60 mg pill

online pharmacy australia

nexium 20 mg price in india

albendazole 400 mg

nexium tablet generic

effexor 300 mg daily

suhagra 100 price

can i order cialis online

internet pharmacy mexico

average cost of cialis daily use

benicar 20 cost

purchase generic cialis online

stromectol 6 mg dosage

propranolol 160mg

propecia 1mg tablets price in india

indianpharmacy com

otc cialis canada

tadalafil tablets uk

pharmacy acyclovir

prednisone no prescription

cost of generic cymbalta 60 mg

zovirax otc drug

sildenafil 20 mg lowest price

pharmacy drugs

sildenafil where to get

viagra us

sildenafil cost in india

phenergan coupon

how much is viagra tablets

gabapentin pill 600 mg

phenergan 12.5

clopidogrel 70 mg

vermox in canada

buy vpxl online

propranolol er 80mg

tadalafil online

where can i order ventolin in canada without a prescription

cialis over the counter australia

zofran medication cost

reddit canadian pharmacy

can i buy cialis online in canada

prednisone 10mg for sale

medicine gabapentin 100mg

generic celebrex costs

cost of hydrochlorothiazide 12.5 mg

gabapentin 667

gabapentin 5027

benicar hct generic

citalopram for depression

celebrex 200mg

mexico viagra pills

modafinil india prescription

where to get viagra in usa

generic prozac online

cialis price europe

cheap propecia no prescription

generic xenical 120mg

anafranil ocd

anafranil for anxiety

propranolol order online

medication cymbalta 60 mg

over the counter viagra online

citalopram 10 mg cost

mexican pharmacies online drugs

levaquin.com

celebrex 20

prozac australia prescription

celexa 60 mg cheap no prescription

medrol 16 mg generic

propecia usa buy

generic sildenafil pills

hydrochlorothiazide 45 mg

neurontin 800mg

1600 mg gabapentin

synthroid.com

tadalafil uk paypal

celebrex non prescription

neurontin medication

silagra 50 mg tablet

valtrex online pharmacy

best viagra over the counter

neurontin 800mg

suhagra 100mg price

effexor brand name

cialis 5mg price canada

robaxin 150 mg

albendazole price usa

how do i get propecia

levaquin tablets

buying synthroid online

buy viagra online from india

cialis us pharmacy

buy suhagra 50 mg

generic viagra otc

order synthroid without prescription

suhagra pills

online pharmacy metformin

prednisone 25mg from canada

60 mg cymbalta

prozac cost uk

canadian viagra 200 mg

anafranil cost

ivermectin canada

baclofen 20 mg buy without prescription

benicar tablet

cheap plavix 75 mg

clomid 400mg

buy benicar online

prednisolone uk buy

generic celebrex 200mg

anafranil 10 mg tab

cialis generic 20 mg price

cheap xenical uk

usa pharmacy online viagra

vpxl for sale

cost of augmentin

buy suhagra 50mg

propranolol brand name us

zestril coupon

buy paxil online canada

albendazole 400 mg tablets price

generic cialis australia

zovirax cream

valtrex 1g

otc tadalafil

augmentin script

generic cialis fast shipping

misoprostol over the counter united states

buy effexor xr generic

10 mg trazodone

how much is zoloft generic

viagra 100 mg cost

zoloft.com

buy lyrica uk

amoxicillin 500mg price in canada

generic citalopram 20 mg

albuterol online pharmacy

buy viagra usa online

plavix cost in india

can you order zanaflex online

plaquenil medication

how to get trazodone prescription

[url=https://elimite.cfd/]acticin without prescription[/url]

erectafil 40 mg

bactrim coupon

buy viagra online europe

zestoretic 20-25 mg

augmentin 250 mg tab

where can i buy albendazole over the counter

viagra 30 mg

how much is hydrochlorothiazide

prednisolone 5mg tablets

dexamethasone drug

medication zestoretic

citalopram 207

can i buy elimite over the counter

inderal la 80

acyclovir tablet

kamagra gel online uk

cost of valtrex canada

trental coupon

trustworthy online pharmacy

zoloft.com

modafinil online fast delivery

phenergan prescription

oder trazadone for sleeping

buy tadacip online uk

prednisone 100 mg

zanaflex for back pain

cheapest paroxetine

buy prednisone without a prescription best price

buy trental 400 mg online india

cephalexin for sale uk

zoloft brand name cost

generic for buspar

cheap lyrica

tizanidine 2mg medication

lyrica australia

how to get misoprostol online

zovirax 400 mg price

diflucan rx online

tretinoin cream online uk

strattera brand name

can i buy amoxicillin in mexico

aurogra 100 for sale

zoloft india

desyrel for insomnia

sildenafil gel

prazosin sleep aid

trazodone 75 mg

buy cialis online without prescription

buy lyrica cheap

aurogra

hydrochlorothiazide 100 mg

zestoretic 20 12.5 mg

lyrica 15 mg

trental er

zoloft 25

prednisolone 5 mg tablet without a prescription

deltasone price in india

accutane cost in india

antabuse buy

can you buy levitra over the counter

levaquin pill

vermox generic

trazodone brand name in india

lopressor 100 mg tab

cephalexin 250 mg tab

advair diskus price

metformin price australia 500mg

quineprox 40

bactrim 200 40 mg

plavix clopidogrel

strattera generic cost

wow, awesome post.Much thanks again. Fantastic.

cost of hydrochlorothiazide

buy anafranil

hydroxychloroquine prices

order buspar online

modafinil india online

how much is generic zoloft

prazosin 1mg

plavix over the counter

best generic glucophage

reliable rx pharmacy

cost of hydrochlorothiazide

generic atarax online

prednisone 40 mg price

levaquin buy online

cleocin hcl 300 mg

generic motilium

amoxicillin price 500 mg

zoloft brand name price

elimite 5 cream price

tizanidine discount

disulfiram tablets 250 mg price

cialis 20 mg price in canada

buspar price canada

prescription meds without the prescriptions https://medrxfast.com/# canadian online drugstore

buy lioresal online

hydrochlorothiazide canada

strattera price

buy kamagra india online

cialis how to

albendazole buy canada

bactrim ds antibiotic

advair diskus coupon

baclofen 30 mg

canadian pharmacy in canada

valtrex 500 mg generic

how to buy cialis in australia

effexor 74mg

albendazole 200mg

prednisolone 15 mg

amoxil drug

tetracycline capsules 250mg

citalopram for sale

cipro 500mg india

anafranil 25 tablet

prednisolone 5 mg tablet

disulfiram drug brand name

bactrim script

buy albendazole on line

trazodone no rx

azithromycin 250mg generic cost

buy phenergan 25mg nz

singulair medication price

modafinil brand name

malegra 100 mg for sale

drug keflex

plavix medication price

plaquenil hydroxychloroquine

permethrin cream for sale

tetracycline 324

tizanidine 4mg price

amoxicillin online fast delivery

effexor price

albendazole for sale uk

how much is strattera

order celexa online

motilium 10 mg

ampicillin 500

purchase advair online

cheap flagyl pills

hydroxychloroquine-o-sulfate

prednisolone purchase uk

amoxicillin canada price

where can you buy retin a

buy deltasone online

buy trazodone not generic without a prescription

phenergan 10mg uk

canadian pharmacy effexor

where to buy anafranil

discount desyrel

pharmacy online shopping usa

buy chloroquine phosphate australia

celebrex 200mg capsule cost

diclofenac gel brand name in india

propranolol tablets

flomax generic cost

strattera 40 mg cost

albendazole canada

no prescription zoloft

flagyl prescription

noroxin medication

Major thankies for the post.Much thanks again. Much obliged.

phenergan 12.5 mg tablets

generic plavix

tizanidine 4mg tablets

where can i get zoloft

anafranil tablet 10 mg

levaquin drug

albendazole online uk

cialis 10

kamagra oral jelly next day delivery

cost of strattera 80 mg

where to order retin a with no prescription

hydroxychloroquine 0.5

trental 40 mg

strattera generic

zoloft 2 50mg

cheap cytotec pills

buy strattera online canada

azithromycin australia

acyclovir 400mg tab

ordering hctz on lind

plaquenil generic cost

online pharmacy modafinil uk

zoloft tablets australia

generic diflucan 150 mg

dexamethasone cost uk

otc strattera

motilium over the counter australia

cheap flagyl pills

purchase stattera

valtrex without presciption

acyclovir price canada

order albendazole

buy albendazole without prescription

https://diflucan.life/# where to purchase diflucan

generic cialis 5mg online

atarax 25 mg tablet

anafranil

avloquin

trazodone no rx

fildena 50 online

cheap strattera

trental 400 online purchase

provigil drug

hydrochlorothiazide otc

price of metformin 500mg tablets

plaquenil depression

6 mg dexamethasone

atarax 10mg tablet price

trazodone buy online

generic celebrex 200mg price

buy sumycin without prescription

buying albendazole online without a prescription

buy zentiva hydroxychloroquine

how to get acyclovir

lexapro for sale uk

modafinil online fast delivery

can you buy viagra online without a prescription

prednisolone tablets over the counter

lopressor xl

erectafil

buy cheap effexor

buy toradol online no prescription

buy baclofen 10 mg

anafranil price in us

zovirax 5 cream coupon

phenergan buy online

aurogra 100

buspar generic

cymbalta brand

buy malegra 200 mg

best price levitra generic

finasteride uk price

[url=http://citalopram.fun/]cheapest citalopram online[/url] [url=http://prednisone.date/]deltasone otc[/url] [url=http://plavix.site/]price of plavix in india[/url] [url=http://atarax.fun/]buy atarax over the counter[/url] [url=http://albenza.site/]albendazole canada price[/url] [url=http://cleocin.fun/]how much is clindamycin 150mg[/url] [url=http://lyrica.icu/]generic lyrica 2017[/url] [url=http://sumycin.site/]tetracycline without prescription[/url]

malegra 100 from india

cost of generic propranolol

ampicillin for sale online

ciprofloxacin 500mg for sale

toradol generic medication

generic lexapro canada pharmacy

trazodone 50 mg cheap

avloclor

amoxicillin online australia

plavix 600 mg daily

plaquenil 100

aurogra 100 online

buy prednisone online canada

buy cheap levaquin

buy cheap hydrochlorothiazide

clopidogrel medicine

[url=https://promethazine.site/]phenergan over the counter[/url]

buy generic viagra in us

can you buy antabuse online

zanaflex for sale

albendazole 2 tablets 200mg

fildena 50 online

viagra canadian

cost of strattera in canada

diflucan over the counter

Im obliged for the blog post.Really thank you! Keep writing.

albenza for pinworms

buspar 15 mg tablet

tetracycline generic brand name

misoprostol uk

bactrim canadian pharmacy

how to get wellbutrin prescription

where to buy albendazole

order albendazole online

tizanidine 4mg cost

tadalafil pills 20mg

Muchos Gracias for your article post.Much thanks again. Keep writing.

https://valtrex.icu/# buy valtrex without get a prescription online

albendizolewithoutprescription.com

zestoretic 20

levaquin 750 mg

aurogra 100mg tablets

online pharmacy discount code

bupropion 100mg tablets

amoxicillin 500 mg capsule

tetracycline 500 mg online

toradol canada

cialis 20 mg tablet cost

buy generic zoloft online

lisinopril 2 mg

generic zanaflex cost

flomax discount

fluconazole 150mg order

strattera generic usa

cephalexin tablet price

provigil buy australia

20 mg cialis

malaraquin

cymbalta 5mg

tetracycline generic

viagra online cost

glucophage price canada

baclofen cheapest

tizanidine 4 mg brand name

advair drug

best online pharmacy

trental 400 mg price uk

buy clindamycin cream online uk

toradol rx

buy cialis pharmacy

albendazole tablets buy online

generic anafranil

motilium 100 mg

inderal purchase

tizanidine 4mg tablets

generic cialis uk pharmacy

phenergan 12.5mg tab

cheap plavix generic

trental 400 mg cost

order glucophage online

celebrex script

finasteride 0.1

hydrochlorothiazide 12 mg

doxycycline 200 mg

dapoxetine 30 mg tablet

I really like and appreciate your blog post.Really looking forward to read more. Fantastic.

propranolol 10

best price for hydrochlorothiazide

disulfiram drug brand name

can you buy antabuse online

modafinil tablets online

modafinil 100

metformin online no prescription

buy doxycycline hyclate 100mg without a rx

how to buy propecia

60 mg prozac

I really enjoy the blog article.Really thank you! Much obliged.

200 seroquel

where to buy levitra online no prescription

buy fluoxetine online canada

tamoxifen online australia

reputable canadian pharmacy

metformin 850

buy levitra india

budesonide discount

https://paxil.tech/# paxil for ocd

Are you writing the articles in your website yourself or you outsource them?

I am a blogger and having difficulty with content. Other bloggers told

me I should use an AI content writer, they are actually pretty good.

Here is a sample article some bloggers shared with me. Please let me know what your opinion on it and

should I go ahead and use AI – https://sites.google.com/view/best-ai-content-writing-tools/home

cephalexin uk

celexa 40mg

prozac 15 mg

where can i buy prednisolone tablets

seroquel sleep aid

fluoxetine 20 mg tablets

ventolin 100 mg

triamterene hctz 37.5 25 mg cp

vermox otc uk

buy fildena

prozac from canada

Thanks a lot for the blog.Really thank you! Cool.

buy keflex 500 mg uk

enalapril hydrochlorothiazide

price of zestril 30 mg

sildalis 100mg 20mg

atarax tablet price

atarax 25

buy silagra in australia

dexamethasone price south africa

legitimate mexican pharmacy online

valtrex online no prescription

flagyl order online

prozac prescription uk

trazodone 150

brand name abilify

modafinil for sale uk

buy estrace no prescription

sildenafil 50 mg tablet

price of zestril

albuterol india

tadacip 20 tablet

big pharmacy online

sildalis 120 mg

prednisolone 5mg price

tizanidine generic 4mg

diflucan 50mg

celebrex medication online

viagra for men for sale

can you buy albuterol

allopurinol canada

online drugs valtrex

how much is lisinopril 10 mg

cost of synthroid 88 mcg

This is one awesome article post.Really thank you! Awesome.

metformin prescription

buy avana 50 mg

nexium tablet price in india

triamterene-hctz 37.5-25 mg capsules

budesonide cost uk

avana 77573

cymbalta prescription

robaxin without prescription

ordering antabuse

lasix 20mg for sale

diclofenac medicine

prescription medication atarax

[url=http://levitra.sbs/]vardenafil generic price[/url]

albendazole 400 mg price in india

provigil generic

motrin 1000

QuiCk Hit If a patient presents with COPD exacerbation the following steps are appropriate CXR agonist and anticholin ergic inhalers Systemic corticosteroids antibiotics Supplemental oxygen Noninvasive positive pressure ventilation NPPV if needed see Clinical Pearl QuiCk Hit Signs of acute severe asth ma attacks Tachypnea diaphoresis wheezing speaking in incomplete sentences and use of accessory muscles of respiration Paradoxic movement of the abdomen and dia phragm on inspiration is sign of impending respira tory failure. ivermectin for humans walmart

buy fluconazole online

generic viagra without rx

hydrochlorothiazide 25 mg online

buy orlistat uk

provigil mexico prescription

buy celexa without prescription

can i buy nexium over the counter in canada

order modafinil usa

proscar for women

tadacip 5mg online

cheapest levitra 20mg

plaquenil for sarcoidosis

buy tadacip 10

orlistat generico

generic seroquel 400 mg

https://deltasone.icu/# prednisone 5mg cost

seroquel 2019

how to buy viagra online without prescription

lopressor pill

best generic provigil

sildalis in india

propranolol prescription medicine

amitriptyline 2.5 mg

where to buy dapoxetine

buying prozac online

xenical capsules price

plavix online pharmacy

fildena price

where can i buy kamagra gel

plaquenil

tamoxifen without prescription

I truly appreciate this blog post. Cool.

suhagra tablet online

kamagra 100 usa

can you buy amoxicillin online

cheap generic levitra

ventolin hfa inhaler

tadalafil 5mg price canada

aciclovir 5% cream

cheap plavix

buy allopurinol 300 mg online uk

prescription viagra usa

viagra india online pharmacy

where can i get antabuse pills

malegra 200 mg for sale

prednisolone for sale uk

buy generic levitra in usa

nolvadex 10 mg tablet

buy voltaren tablets

can i purchase prednisone without a prescription

antabuse online uk

doxycycline 100mg acne

strattera capsule

0.5 albuterol

fluoxetine 16 mg

cost of strattera tablets

buy provigil online with paypal

where to buy tadacip online

cheapest cialis online india

how to get prednisone

robaxin otc in canada

prednisolone buy uk

[url=http://suhagra.fun/]suhagra 50 mg buy online india[/url]

orlistat 120 mg online

accutane canada pharmacy

metformin in europe

metformin for sale uk

generic lasix 40 mg

trazodone price canada

Very neat article.Really thank you! Really Great.

malegra 100 mg for sale

estrace cream price canada

nexium for daily use

prednisolone 15 mg

hydrochlorothiazide 25 mg without prescription

purchase doxycycline online

seroquel generic cost

strattera sale

propecia cheapest no prescription

feldene 20 mg tablets

I cannot thank you enough for the post.Much thanks again. Really Cool.

https://paxil.tech/# paxil 60 mg

purchase motrin 600

ventolin price uk

fluoxetine hcl 20mg

best price for piroxicam

how to get accutane uk

plaquenil 200mg cost

kamagra 4 uk

metformin 1000 mg pill

doxycycline 400 mg price

atarax tablet price in india

prozac capsule 20mg

generic propecia india

400mg modafinil

dexamethasone 8 mg tablet

how to get modafinil in canada

xenical cost nz

buy seroquel 100mg

web pharmacy

buy yasmin pill usa

accutane online prescription

budesonide 250 mcg

xenical roche

celexa prescription

viagra 100mg price in india online

canadian levitra

fildena online pharmacy

tizanidine 2018

buy suhagra 25 mg

nolvadex for sale online

average cost cialis

cymbalta tablet

vermox canada where to buy

where to buy valtrex online

cost of seroquel

how can i get dapoxetine

buy viagra pharmacy

zestoretic 20 25

levitra brand name

budecort usa

silagra 100 price in india

generic for tetracycline

levaquin 500

12 mg hydrochlorothiazide

order modafinil

where can i buy ventolin in uk

tamoxifen for sale uk

how to get fluoxetine

buy inderal 40 mg

buy fluconizole online

ampicillin buy online uk

budesonide online pharmacy

buy prednisolone 5mg tabs

ventolin buy

prednisone 20mg prescription cost prednisone 500 mg tablet

atarax anxiety

budesonide tablets cost

vermox 500mg tablet

trental 400 mg price

levitra best price uk

order zanaflex online

allopurinol 300 mg cost

https://finasteride.top/# propecia uk

buy priligy online uk

canadian family pharmacy

cheap levaquin

where can you buy diflucan over the counter

can you buy diflucan online

450mg prednisolone

generic robaxin 500mg

hydroxychloroquine 70 mg

augmentin 600

synthroid 112 mcg price

cialis daily 2.5 mg cost

viagra 100mg price india

[url=https://accutane.wtf/]accutane rx[/url] [url=https://dutasteride.fun/]buy avodart uk[/url] [url=https://zestoretic.fun/]zestoretic 20[/url] [url=https://piroxicam.fun/]piroxicam coupon[/url] [url=https://lisinopril.site/]lisinopril 40 mg daily[/url] [url=https://ampicillin.site/]ampicillin 100[/url] [url=https://fluoxetine.life/]prozac otc[/url]

propecia cost over the counter

pharmacy wholesalers canada

prednisolone 60 mg daily

dapoxetine pills

lisinopril 2.5 mg coupon

buy plaquenil in india

buy motrin 800

how to get propecia prescription online

levitra price in australia

Thanks-a-mundo for the post.Thanks Again. Awesome.

hydrochlorothiazide 12.5

viagra cheapest pharmacy

otc albuterol usa

where to buy viagra online uk

albuterol coupon

allopurinol buy online

valtrex prescription canada

trazodone 150 mg tablet

india pharmacy metformin 500 mg

cost of estrace cream without insurance

order nexium

silagra pills in india

promo code for canadian pharmacy meds

diflucan 200 mg pill

levaquin pill

atarax 40 mg

generic viagra coupon

zestoretic 20 25 mg

discount cialis prices

lasix tablets 20 mg

[url=https://diclofenac.fun/]diclofenac pills 50 mg[/url]

buy modafinil online

tadalafil capsules

albuterol inhaler prescription

synthroid 75 mcg india

zanaflex 2mg tablet

buy albuterol tablets uk

how to buy valtrex without a prescription

can you buy zoloft

vardenafil 5mg

buy flomax

cheap bactrim

https://hydroxychloroquine.icu/# plaquenil 5 mg

where can you buy clomid over the counter

generic synthroid online

azithromycin cost canada

lipitor generic canada

budesonide 9 mg price

buy sildenafil generic

hydroxychloroquine oral

erectafil 20 mg

zoloft 100mg price

buy tadacip 20

combivent aer respimat

best price genuine viagra

accutane 20 mg buy online

can you buy diflucan without a prescription

medication diclofenac gel

zoloft generic brand

buy buspar uk

where can i buy celebrex

generic lipitor 20 mg

synthroid cost

vardenafil 20 mg price

sildenafil generic coupon

cheap wellbutrin

robaxin 250 mg

I think this is a real great blog. Will read on…

how much does propecia cost

trazodone 100mg

strattera 80 mg price

tadalafil generic coupon

gabapentin buy usa

strattera pill

price of synthroid without insurance

buy trental

cipro 500 mg

combivent inhalation aerosol

where can you buy viagra for women

lopressor 50

cheap levitra 10mg

zoloft buy canada

ivermectin 10 mg

how much does ivermectin cost

cost generic augmentin

provigil daily use

where can i buy stromectol

stromectol price

valtrex 500 mg generic

levitra plus

Appreciate you sharing, great blog article. Much obliged.

prescription drug triamterene

malegra 100

where to buy cheap cialis online

levitra for sale canada

anafranil for anxiety

female viagra price in india

viagra 100mg canada

modafinil online australia

erythromycin drug

tadalafil cheapest price

zoloft australia

amoxicillin 625mg tablet price

tadacip online canada

where to buy accutane uk

viagra tablets for sale uk

buy tadacip from india

amitriptyline uk buy

buy tadacip online uk

where to get vermox

triamterene-hctz 75-50

lyrica 300 mg for sale

buy cheap robaxin

zoloft over the counter price

buy robaxin australia

baclofen 20 mg price in india

elavil pills

lasix 120 mg

propecia otc

synthroid 88 mcg coupon

cheap clopidogrel

erectafil 5

cheap baclofen uk

buy robaxin without prescription

best place to buy propecia online

budesonide 9 mg tablets in india

medicine levitra 20mg

triamterene-hctz 37.5-25 mg tb

buying viagra without prescription

prescription medication without a prescription lasix

doxycycline online for dogs

albuterol canadian pharmacy no prescription

https://antibiotic.icu/# doxycycline 100mg capsules

viagra online without prescription usa

50mg viagra

proscar for sale australia

buy clonidine without prescription

provigil 200 mg pill

modafinil 2017

flomax 21327

anafranil 75 mg price

where to get modafinil

australia online pharmacy free shipping

where to buy colchicine in singapore

citalopram 10 mg cost

viagra for sale in ireland

propranolol 30 mg tablet

viagra soft tabs 100mg pills

lexapro for sale uk

where can i buy azithromycin 500mg

strattera prescription cost

sildenafil 25 mg

zoloft price without insurance

otc desyrel

malegra 100 mg for sale

buy baclofen in uk

india cialis online

allopurinol brand name in india

retino 0.05

lasix tablet cost

can you buy propecia over the counter in canada

tizanidine 4mg

international online pharmacy

cheap prescription nexium

erythromycin capsules 500mg

triamterene/hctz 37.5-25 mg

buy fildena 150

levitra for sale

purchase zanaflex online

propecia cost australia

buy modafinil pills

buy cheap levitra online

fluoxetine 20mg cost

where can i buy generic cialis online

propecia 1mg tablets

clomid generic

propecia cheap

modafinil mexico over the counter

piroxicam cream

best propecia brand

lyrica 75mg

3 baclofen

tadacip 20 mg online india

can i buy viagra otc

provigil online order

order anafranil online

accutane cost canada

nexium tablets

where can i get voltaren gel

buy proscar 5mg online

triamterene hctz 75 50 mg

zoloft 250 mg

zestoretic 20-25 mg

cialis com

tadacip 40 mg

buy vermox online usa

zanaflex online india

cialis by mail

budesonide 9 mg capsules

nexium otc canada

buspar 30 mg tab

xednical

gabapentin canada over the counter

drug elavil

https://amoxicillin.pro/# amoxicillin 500 capsule

retino 0.05 gel

synthroid 1.25 mg

desyrel 100 mg tab

average price of celexa

propecia compare prices

lopressor 25 mg tablet

buy propecia online south africa

buy female viagra online cheap

robaxin 750 canada

zanaflex 4 mg capsule

amoxicillin 500mg online uk

can you buy elimite over the counter

propranolol online order

erythromycin 250

[url=http://onlinepharmacy.moscow/]online canadian pharmacy coupon[/url]

diclofenac brand in india

medicine clopidogrel 75 mg

buy zoloft usa

metformin south africa

generic zestoretic

zanaflex sleep

inderal brand name

lopressor er

trental

synthroid 25 mg daily

furosemide 100 mg tablets

propranolol price

generic propecia 5mg

albuterol 5

sildenafil 150 mg

zoloft pill 25 mg

sildenafil 20 mg pill

700 mg amitriptyline

anafranil 25 tablets

nexium tablets best prices

canadian pharmacy online albuterol

amitriptyline drug 1500 mg

order cialis from india

silagra 100 mg india

silagra online india

trazodone without prescription

buy prednisone cheap

generic for citalopram

anafranil price in india

fildena 120

synthroid 0.050

female viagra where to buy uk

propecia online

nexium prices us

[url=http://cytotec.best/]cytotec cost in south africa[/url]

can you order zanaflex online

stromectol order

buy cialis online canada pharmacy

best generic finasteride

gabapentin 250 mg

generic for hydroxychloroquine 200 mg plaquenil 200mg tablet cost

nexium price in south africa

amitriptyline uk pharmacy

buy strattera online canada

amoxicillin 875 mg coupon

malegra dxt

generic malegra

amitriptyline 50 mg cost

levitra mexico pharmacy

drugs dark web reddit darknet markets up

https://tadalafil.pro/# tadalafil 20mg pills

buy stromectol

malegra dxt tablets

cheap propecia 1mg

provigil

silagra uk

keflex without prescription fast shipping

provigil buy online usa

anafranil for sale

5 mg tadalafil coupon

buy azithromycin 1000 mg

anafranil online india

celexa canada

best buspar generic

propecia purchase uk

buy erythromycin

generic zoloft best price

medical pharmacy south

lipitor australia

pharmaceutical online ordering

prices generic cialis

best generic finasteride

can i buy flomax over the counter

erectafil 5mg

how to buy propecia

xenical roche

malegra 25 mg

neurontin prescription

how much is cialis in mexico

1000 mg valtrex daily

how to get accutane australia

buy bactrim over the counter

viagra best brand

how much is accutane

buy generic cialis online usa

baclofen 10 mgs no prescription

where can i get trazodone

generic lipitor 10mg

accutane online no prescription

metformin hcl 1000mg

where can i buy ciprofloxacin over the counter

prozac 40 mg tablets

illegal black market how to buy from the darknet markets

dark web poison sichere darknet markets 2022

what darknet market to use dark websites

dark web drugs ireland bohemia darknet market

onion seiten 2022 deep sea darknet market

dark web store the onion directory

dream market darknet darknet market list url

darknet selling drugs darknet markets availability

how to access darknet markets reddit dynabolts pills

alphabay market net versus darknet market

dark markets usa naked lady ecstasy pill

dark net market links 2022 Abacus Market darknet

site darknet market darknet search

tor search engine link working dark web links

мега купить мега скорость

best onion sites 2022 dark markets norge

dark markets south korea dark web search engines 2022

how to access the dark web safely reddit berlin telegram group drugs

retino 0.5 cream price

monero darknet markets dark markets indonesia

Cocorico link dark markets belarus

мега шишки mega onion зеркало

dark markets ireland new darknet markets

mega onion ссылка мега onion

dark markets norway buy drugs from darknet

onion live best market darknet drugs

deep web drugs weed only darknet market

vice city link darknet market list links

darknet market comparison black market url deep web

даркнет магазин darknet магазин

onion directory 2022 online black market uk

lexapro prices

tor market nz how big is the darknet market

reliable darknet markets reddit dark web market

how to buy valtrex online

buying drugs online on openbazaar dark web market links

darknet in person drug sales darknet markets reddit

dark web drugs bitcoin decabol pills

darkweb market darknet selling drugs

top online pharmacy india

monero darknet markets cannahome darknet market

ссылки на даркнет мега магазин

darknet market noobs step by step superlist darknet markets

ethereum darknet markets darknet reinkommen

darknet market superlist darknet market updates 2022

propecia/finasteride

darknet drug markets reddit dark markets norway

darknet market buying mdma usa how to use darknet markets

cypher market darknet

dark web sales darknet markets still up

best working darknet market 2022 where to find onion links

dark markets san marino darknet market for noobs

магазины даркнета mega даркнет

onion live marijuana dark web

buy drugs on darknet reddit darknetmarket

deep dark web versus market url

how to use deep web on pc dark markets finland

hidden wiki tor onion urls directories darknet markets onion addresses

step by step dark web dark websites reddit

Heineken Express darknet trusted darknet vendors

black market alternative how to use darknet markets

deep net access darknet drug market url

dark web hitman for hire darknet markets list reddit

darkmarket website darknet market black

deep web drug url darknet markets list 2022

best darknet markets for marijuana dark markets malaysia

deep web market links reddit top darknet market 2022

dark markets paraguay darknet paypal accounts

top onion links darknet markets norway 2022

мега onion зеркало сайт мега

black market online website deep dark web markets links

best dark web marketplaces 2022 darknet markets wax weed

dark markets monaco Cocorico url

french dark web top 10 dark websites

мега шишки мега сайт ссылка

versus market darknet best darknet markets 2022

tor link search engine top onion links

darknet drug markets which darknet markets accept zcash

darknet link drugs darknet market vendors

darknet drugs shipping darknet black market url

как зайти на мегу мега кокаин

how to get to the black market online best dark web marketplaces 2022

магазин даркнет сайт мега

darknet market noobs guide reddit darknet markets noobs

darknet markets reddit onion links 2022

trusted darknet markets Heineken Express darknet Market

site onion liste how to shop on dark web

darknet drugs reddit reddit darknet market deals

dark markets china reddit darknet market australia

monero darknet markets dark markets hungary

buying darknet drugs darknet market link updates

We call this approach Binary Biology cialis cost

dark web engine search dark web drugs

мэги сайт мега даркнет

dark markets netherlands deep web onion url

dark markets greece darknet markets onion address

darknet vendor reviews dark markets bosnia

versus project market

lsd drug wiki dark web market links

bohemia market link darkfox darknet market

dark markets greece best working darknet market 2022

trusted darknet markets deep web marketplaces reddit

drug markets dark web reddit darknet reviews

darknet магазин новое зеркало мега

darknet market search engine onion market url

dark markets paraguay darknet market vendor guide

dark markets poland reddit biggest darknet market place

darknet drugs price cannazon market darknet

verified darknet market best darknet market for weed uk

underground card shop darknet reinkommen

black market website carding deep web links

how much is metformin

how to buy bitcoin and use on dark web black market website

best darknet markets for vendors bohemia link

search deep web engine darknet markets norway 2022

most popular darknet markets 2022 dark markets singapore

darkweb sites reddit pyramid pill

dark web links site darknet onion

ethereum darknet markets reddit darknet market guide

retin a generic cost

reliable darknet markets reddit reddit darknet market list

how to get to darknet market safe alphabay market onion link

магазин мега mega ссылка

darknet market sites darknet drugs

dark web marketplace buying on dark web

dark web steroids deep web search engines 2022

where can i buy over the counter cialis

effexor 375 mg

cannazon market darknet market noobs

как зайти на мегу мега купить

dark web directory dark markets thailand

deep web drugs dark market 2022

best darknet market for weed 2022 dark web live

dark web steroids darknet market list reddit

mega зеркало mega onion ссылка

darknet market noobs step by step darknet search

ссылка мега мега зеркало

darknet market search vice city market url

darknet market litecoin drugs on the darknet

darknet market iphone reddit darknet market deals

best darknet market urs hidden uncensored wiki

darknet sites drugs alphabay market url

monero darknet market asap link

bupropion sr 150 mg tablets

darknet market noobs hitman for hire dark web

phenylethylamine Kingdom Market link

dark web drugs nz bitcoin dark website

мега нарко ссылки на даркнет

dark markets moldova australian dark web markets

how to get on darknet market black market websites 2022

clonidine hydrochloride 0.1 mg

access the black market

cannazon url top onion links

tor market links xanax darknet reddit

darknet market oxycontin best darknet markets for vendors

vice city market link cannabis dark web

darknet магазин даркнет сайты магазин

buying from darknet market with electrum most popular darknet market

darkmarket dark web sites xxx

anafranil 25 mg mexico

lasix price india

list of online darknet market popular dark websites

darknet drug markets 2022 dark web links adult

darknet illegal market superlist darknet markets

deep market buy drugs from darknet

Heineken Express url best darknet market urs

dark web steroids fresh onions link

dark markets switzerland best darknet market 2022

monero darknet markets darknet drugs malayisa

onion link search engine safe darknet markets

darknet telegram group dark web market list

incognito market link darknet drug prices

black market alternative Cocorico Market darknet

uncensored hidden wiki link darknet market sites

dark web search engines link darknet drugs australia

магазины даркнета как зайти на мегу

darknet market xanax darknet markets noob

tfmpp pills versus project link

benicar online pharmacy

most reliable darknet markets Kingdom darknet Market

ссылки на даркнет сайт даркнет

i2p darknet markets best darknet market australia

darknet marketplace drugs reddit darknet market uk

what is escrow darknet markets darknet market canada

официальный сайт мега мега даркнет

darknet market iphone fullz darknet market

mega market ссылка мега

best deep web markets dark web links 2022 reddit

underground market online black market net

dark web drugs nz dark markets andorra

dark web search engines 2022 trusted darknet markets weed

black market online black market buy online

counterfeit money dark web reddit deep deep web links

tor darknet market address currently darknet markets

darknet market dash deep web deb

bitcoin cash darknet markets blackweb darknet market

darknet markets address dumps shop

как зайти на мегу мега онион сайт

dark web sites xxx dark web hitman for hire

darknet market onion links

list of darknet markets reddit darkmarkets

dark markets belarus live dark web

silagra 100 online

dark web in spanish darknet market vendor guide

archetyp market link darknet market links 2022 reddit

buy darknet market email address dark web market reviews

dn market dark web cvv

darknet list market buy drugs online darknet

мега вход мега онион

onion directory buy drugs from darknet

buying credit cards on dark web darknet market list url

Cocorico Market link the real deal market darknet

versus market url black market webshop

bohemia market link drugs dark web

the dark web shop cannahome market link

cialis canada 20mg

darknet market search darknet markets wax weed

deep web search engines 2022 darknet market url

drugs on darknet dark markets philippines

underground black market website bohemia market

buying from darknet market with electrum tor2door market link

incognito market darknet how to buy from the darknet markets lsd

darknet drug trafficking dark markets san marino

onion links credit card darknet drug trafficking

mega onion shop mega onion ссылка

black market buy online current darknet market list

dark markets estonia incognito market url

мега onion зеркало мега onion зеркало

darknet drugs india black market buy online

darknet market ddos onion directory

dark web live best lsd darknet market

best card shops dark web markets 2022 australia

how much is zanaflex cost

trusted darknet vendors black market website names

мега онион сайты даркнет ссылки

мега onion darknet сайт

dark net markets dark markets india

reddit darknet market links tma drug

darknet reinkommen deep web links reddit

darknet drugs sites adresse dark web

access the black market dark web sites xxx

onion market url drug markets dark web

dark web links adult dark markets hungary

darknet online drugs darknet market dash

Kingdom link dark web market place links

tor markets links dark web sites links

what is the darknet market dark markets uruguay

redit safe darknet markets darknet seiten dream market

Cocorico url

cannazon link dark markets serbia

мега официальный сайт мега onion ссылка

incognito market url tor2door market darknet

top darknet markets list cp links dark web

darknet markets without login buy bitcoin for dark web

purchase allopurinol

darknet market controlled delivery darknet list

synthroid medication price

top ten dark web dark markets denmark

furosemide 10 mg price

darknet website for drugs how to buy drugs on darknet

сайт мега мега onion зеркала

silagra 100mg price

best darknet markets uk best darknet drug market 2022

shop ccs carding monkey xtc pill

safe list of darknet market links current best darknet market

how to use onion sites deep web cc dumps

tor marketplace darkfox market link

darknet drugs 2022 reddit darknet market list

top dark net markets darknet websites wiki

darknet market forum dark web market

gray market place the dark web links 2022

bitcoin dark web best darknet market 2022

darknet links 2022 drugs how to get on the dark web android

dark markets finland step by step dark web

fluoxetine capsules

dbol steroid pills how to access darknet markets reddit

darknet reinkommen reliable darknet markets lsd

black market websites tor best darknet markets for marijuana

mega onion оффициальный сайт сайты даркнет ссылки

dark web prostitution online black market electronics

onion links for deep web we amsterdam

ссылки на даркнет зайти на мегу

what darknet markets are up how to use onion sites

alphabay url dark markets colombia

prices pharmacy

adresse onion black market darknet markets up

450 wellbutrin

generic vardenafil canada

dark web fake money black market online website

alphabay solutions reviews darknet market links safe

darknet markets australia darknet market links buy ssn

мега onion оффициальный сайт сайты даркнет

darknet drugs malayisa dark web market place links

mega onion shop магазин даркнет

what bitcoins are accepted by darknet markets reddit darknet market superlist

active darknet markets nike jordan pill

dark markets estonia alphabay market net

dream market darknet url deep web drugs

australian darknet vendors dark markets norway

asap link brick market

darknet market comparison chart alphabay market onion link

how to access darknet markets best darknet markets reddit

r darknet market drugs dark web price

price of generic effexor

deep net websites underground website to buy drugs

dark web markets best darknet market 2022

darknet guns market darknet marketplace drugs

can you buy drugs on darknet

darknet market redit cp onion

официальный сайт мега ссылка на мегу

dark markets ecuador onion directory list

darknet adress dxm pills

tor darknet market address Heineken Express Market

uncensored deep web best darknet markets

list of dark net markets gray market place

даркнет сайты магазин ьупф ьфклуе

what darknet market to use now how to buy from the darknet markets

tor market url euroguns deep web

ruonion dark web escrow service

unicorn pill what is darknet markets

augmentin 675 mg

deep dark web best darknet market for weed

zithromax pack

dark markets netherlands guide to darknet markets

dark markets san marino darknet market 2022 reddit

darknet drugs market bitcoin black market

can you buy doxycycline over the counter in nz

onionhub onion tube porn

bitcoin dark web outlaw market darknet

darkfox darknet market black market websites tor

darknet market for noobs australian darknet vendors

purchase real cialis online

best lsd darknet market tor darknet markets

мега onion ссылка даркнет ссылки

dark web live tor2door market link

bitcoin dark website new alphabay darknet market

dark web website links darknet market ddos

mega onion shop darknet сайт

tor2door market darknet vice city market darknet

tor link search engine dark web trading

lexapro 20mg tablet

project versus darknet drugs sites

darkfox darknet market which darknet markets are still open

alphabay market net dark web markets

darknet drug market list counterfeit money onion

deep web links updated best darknet markets reddit

doxycycline 2984

hitman for hire dark web Abacus Market

com cheap ca kamagra thereforeenhances potency of the goal of these factors order cialis

onion deep web search marijuana dark web

search darknet markets credit card black market websites

darknet sites url darknet market prices

mega market мега купить соль

azithromycin 1000mg

adresse onion darknet drugs sales

сайт даркнет mega даркнет

new alphabay darknet market darknet list

shop ccs carding darknet market url

deep market buying things from darknet markets

credit card dumps dark web steroid market darknet

incognito market australian darknet markets

underground market online darknet market 2022 reddit

dark markets bolivia dark markets luxembourg

darknet market carding

мега onion ссылка мега купить

darknet drugs india darknet market links reddit

darknet markets urls best working darknet market 2022

best dark web search engine link darknet market avengers

darknet markets most popular black market drugs guns

darknet market reddit 2022 darknet wiki link

reddit working darknet markets links deep web tor

darknet market controlled delivery tor drugs

мега купить mega онион сайт

dark web poison guide to darknet markets

alphabay url current best darknet market

tor darknet sites dark markets italy

working dark web links best darknet market for weed uk

dark markets italy underground market place darknet

darknet list gbl drug wiki

working darknet markets best darknet market for psychedelics

darknet markets norway 2022 onion directory list

dark markets czech republic live dark web

project versus darknet markets with tobacco

brucelean darknet market buying drugs on darknet

florida darknet markets currently darknet markets

ссылки на даркнет мега onion

darknet market comparison chart buy ssn and dob

best websites dark web darknet список сайтов

официальный сайт мега mega onion зеркала

darknet market carding fullz darknet market

propranolol medication

dark web sites for drugs darknet marketplace drugs

dark markets slovenia reddit darknet market noobs bible

darknet drug market how to access the dark web through tor

legit darknet markets tor markets 2022

drugs on deep web dark markets ukraine

dark markets turkey best dark net markets

Abacus Market link best darknet market for steroids

how to access dark web markets how to darknet market

dark web address list dark web xanax

darknet markets noob dark web trading

darknet websites drugs cp links dark web

deep web search engines 2022 black market prescription drugs for sale

darknet магазин зелья мега onion

cialis pills

mega onion оффициальный сайт mega даркнет

darknet markets onion address dark chart

darknet список сайтов best dark net markets

order viagra online usa

black market reddit drug market darknet

dark web search tool tfmpp pills

hidden financial services deep web underground dumps shop

dark web directory darknet market vendors

weed darknet market

google black market darknet sites drugs

black market cryptocurrency biggest darknet markets

darknet markets for steroids how to buy from darknet markets

where can i buy real clomid online

сайты даркнет mega market

darknet markets dark web step by step

good dark web search engines best darknet market drugs

dark markets peru best current darknet market

darknet best drugs dark markets hungary

uncensored hidden wiki link dark web link

how to create a darknet market dark markets switzerland

мега зеркало мега сайт ссылка

vice city darknet market dark markets uruguay

bohemia market url buying on dark web

cannahome market darknet dark web buy credit cards

top darknet market now darknet xanax

deep web drug store deep web links

tor2door market url hacking tools darknet markets

dark web adderall archetyp darknet market

celebrex 200mg price

black market online website darknet market vendors

darknet websites wiki darknet websites wiki

dark market url dark net

darknet site free dark web

dark web escrow service access darknet markets

мега онион мега магазин

мэги сайт магазин мега

deep web drug store darkweb marketplace

tor dark web dark web access

darknet market list darknet site

dark market list tor market

darknet магазин зелья mega онион

drug markets onion darknet market list

darkweb marketplace drug markets onion

darknet market links darknet sites

dark internet deep web search

blackweb official website darknet drug links

cephalexin tablets price

darkmarket url best darknet markets

cost of cialis without insurance

darknet marketplace dark web site

16mg zofran

deep dark web darknet market

how to get on dark web deep web drug links

darknet магазин зелья мега сайт ссылка

darkmarket 2022 dark internet

dark web link blackweb official website

black internet bitcoin dark web

dark websites tor market

chlorochin

dark websites deep web drug url

darknet websites drug markets onion

darknet websites free dark web

deep web search deep dark web

darkmarket dark web search engine

darkmarket dark web links

how to get on dark web dark web site

darkmarket link deep web drug url

darknet drug store onion market

propecia online price

tor market url blackweb

dark markets 2022 drug markets onion

darknet market links deep web search

dark markets 2022 darknet market lists

tor dark web dark web drug marketplace

даркнет магазин mega onion оффициальный сайт

dark web search engines darknet markets

darknet drug store dark web sites links

free dark web drug markets onion

darkmarket list dark web links

darknet markets darkmarket

dark web drug marketplace dark markets

drug markets onion darknet websites

arimidex cost canada

dark web market dark web drug marketplace

dark web market links darknet drug store

tor market dark internet

darknet market tor dark web

deep web search dark market link

мега магазин мега onion ссылка

how to access dark web darknet search engine

the dark internet darknet site

dark market onion deep web drug store

darknet links tor market links

darknet drug links tor markets links

darkmarket 2022 darknet drug store

darknet websites tor market url

buy atarax 25mg

darkmarket link bitcoin dark web

dark web websites blackweb

dark web search engine darkmarkets

deep web drug store tor markets links

мега зеркало мега наркотики

clonidine over the counter uk

dark website darknet market list

darknet market links darkmarket

generic cialis soft tabs 20mg

dark web site darknet sites

dark web access darknet websites

deep web markets darknet sites

даркнет сайты магазин mega зеркало

darknet drug store dark web search engines

darknet drugs the dark internet

darknet market how to access dark web

celebrex from canada without a prescription

dark web market list darkmarket url

darknet market links dark market list

dark market url darknet markets

dark market list tor market links

darkweb marketplace darknet market

darknet site darknet market lists

accutane medicine online

darknet drug store darknet search engine

deep web markets darknet marketplace

darknet sites the dark internet

dark web market links deep web drug url

dark markets dark internet

darknet sites onion market

darknet links dark website

darknet drug market best darknet markets

сайт даркнет мега купить соль

darknet links darknet markets

buy zithromax online uk

dark market 2022 dark web links

dark internet deep dark web

inderal pill

dark web sites links dark web markets

0.25 arimidex

black internet deep web drug markets

best darknet markets darkmarkets

how to access dark web dark web drug marketplace

how to get on dark web darknet seiten

aralen 250

tor marketplace dark web sites links

darkmarket dark internet

dark net darknet drug market

onion market darkmarkets

darknet магазин mega ссылка

how much does permethrin cost

dark market url dark market link

darknet drug store deep web drug markets

deep web drug links dark market 2022

dark web drug marketplace darknet sites

drug markets onion dark net

dark web markets blackweb official website

deep web drug url darkmarket link

dark market tor market links

tor dark web dark web market links

dark web sites links deep web links

free dark web deep web drug markets

darkmarket url tor markets

sildenafil 100mg australia

мега сайт ссылка мега даркнет

dark web access deep web drug store

tor dark web darknet market lists

darknet seiten tor darknet

darknet websites tor dark web

dark web search engines dark web links

darknet drugs dark web markets

darkmarket link dark market

bitcoin dark web dark internet

dark web market dark market

мега сайт как зайти на мегу

dark web sites best darknet markets

blackweb dark web market list

darknet seiten darknet drugs

dark web market best darknet markets

dark market 2022 dark web drug marketplace

darknet drug store tor marketplace

dark web links deep web links

darknet drug market dark markets 2022

dark markets blackweb

darkmarkets tor markets 2022

deep web drug url darknet drugs

darknet sites tor market

darkmarket darkmarket 2022

dark markets dark website

bactrim generic cost

darknet drug links darknet marketplace

зайти на мегу сайт мега

deep dark web darknet market links

darknet market list black internet

deep dark web tor markets 2022

tor marketplace darknet marketplace

dark markets dark web link

dark web search engines deep web markets

free dark web darknet market

mega onion ссылка мега onion зеркало

deep web sites blackweb official website

darknet markets dark markets

deep web search dark web access

dark internet tor markets links

deep web drug url dark web websites

dark web search engine darknet drugs

how to get on dark web darknet market links

the dark internet darkmarket

darkweb marketplace darknet market

dark internet darknet sites

dark website darknet seiten

darkmarket 2022 tor marketplace

darkmarkets darkmarket url

dark web market links onion market

how to get on dark web darkmarket list

onion market dark market onion

dark market list darkmarkets

where can i buy wellbutrin without prescription

мега онион мега скорость

dark markets 2022 darkmarket link

darkmarket url darknet sites

deep web search bitcoin dark web

dark web access dark web site

free dark web tor markets 2022

deep web drug store dark web market

dark web sites dark markets 2022

dark market list darknet drugs

metformin buy canada

darknet market list drug markets dark web

dark web market links onion market

dark web site dark market list

how to get on dark web darknet drug links

darknet сайт мега шишки

dark web market links deep web sites

darkmarket url darknet market lists

dark web market dark web search engines

dark market darknet search engine

darknet drug links darkmarkets

dark web sites deep web links

dark markets 2022 dark web market links

dark web search engines dark internet

dark web sites links darknet marketplace

blackweb darknet links

deep web sites how to get on dark web

ссылки на даркнет мега ссылка

how to access dark web dark web access

deep web drug markets darknet drug market

order zoloft online no prescription

deep web drug links black internet

мега онион сайт мега официальный сайт

atenolol brand name

buy paxil online cheap

free dark web deep web search

darkmarket link darknet market

allopurinol 1502

darkmarket 2022 darknet markets

darkmarket 2022 darknet market list

tor market url darkmarket 2022

drug markets onion darkmarket list

blackweb the dark internet

darknet market list darknet websites

deep web links darkmarket url

strattera 25 mg

dark website darkmarkets

deep web sites deep web sites

albendazole cost uk

bitcoin dark web dark website

darknet market lists tor marketplace

dark web sites links darkweb marketplace

dark web link dark net

deep web drug store deep web drug links

dark market link tor markets

dark markets 2022 dark web drug marketplace

dark web websites deep web sites

darknet sites dark market 2022

mega onion mega onion ссылка

deep web drug links darkmarket

deep web drug store dark market list

dark web market list darkmarket 2022