Building an anchor system requires much practice and experience. When dealing with structures, chose anchor points which are part of the inherent structure of the building. This includes columns, beams, anchors for window cleaning equipment, and elevator housings. Avoid corroded metal, weathered stonework, and deteriorated mortar. Avoid using vents, flashing, gutters, and chimneys.

When using a vehicle for an anchor, remove the ignition key, set the brake and chock the wheels. Do not use the bumper. Connect directly to the vehicle frame using such items as the axle, cross member or tow hooks.

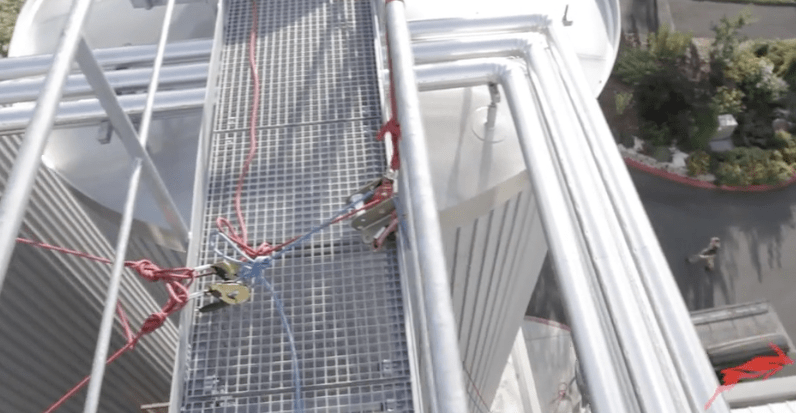

Often a desirable anchor is off to the side of a needed direction of pull. Ideally, they should be directly above and close to the fall line. When this is not possible (which seems to be more times than not) advanced anchor rigging skills come into play, namely, focusing the direction of the main anchor to a viable position.

Anchors Overview

Anchors are the foundation on which we build our rescue systems. Rescuers must quickly decide on an appropriate anchor system for a given rescue situation. Usually, anchors need to be in place before other aspects of the rescue can proceed. Determining where anchors should be built and beginning their construction early are critical steps in timely rescue operations. Here’s a quick review of anchors and related keywords we’ll cover throughout this course:

Anchor

An Anchor is a general term for the combination of everything combined. Single connection point (e.g. tree, boulder, camming device, etc.).

Anchor Point

An Anchor Point is a single object or component used either alone or in combination with others to create an anchor system capable of withstanding a significant force.

Anchor System

An Anchor System is one or more anchor points connected in order to provide a secure connection. Multiple anchor points rigged together creating a redundant system.

Deviation

Redirects the natural fall line of the rope on the rock face. A deviation point may or may not to be subjected to the same force as the primary rig point.

Directional

Rigging technique to change the natural line of a rope with a carabiner or pulley attached to an alternative anchor.

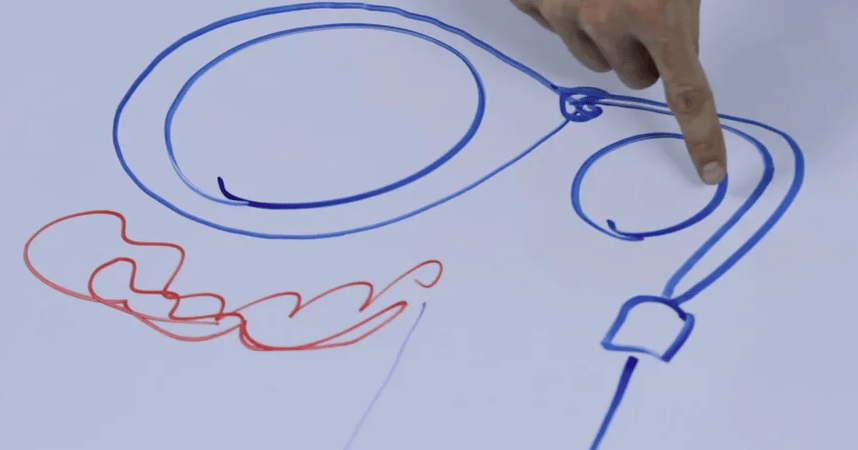

Focal Point

A location, floating or fixed, where all rigging is directed for anchor points. This concept disciplines rescuers to construct rigging which joins together at an efficient point, rather than unwittingly resorting to wherever the knot that joins all anchor points ends up due to the length of material used; the latter can result in an awkward spot to manage rope handling tasks.

We will always try to engineer our anchor systems with housekeeping in mind. Though a single “bombproof” anchor may be strong enough to support an entire rescue system, including multiple load bearing lines, we may still build a second anchor for convenience and cleanliness and to allow more workspace for rescuers. Rescue systems are often more efficient and easier to operate with redundant load bearing lines rigged on separate anchors.

E – Equalized

In a system with multiple anchor points or multiple strands of anchor material, the various components of the anchor system should bear roughly equal parts of the load. Self-equalization is not required. Pre-equalize the anchor for the anticipated direction of pull.

R – Redundant

Failure of any one component of an anchor system should not lead to complete anchor failure. For example, construct the anchor system so that if one strand of software is severed, at least one additional strand capable of supporting the load will remain intact.

N – Non–Extending

Failure or shifting of one element in the anchor system should not cause significant movement of the load. This is why we fix and focus our multi-point anchor systems and why we generally avoid self-equalizing anchors. The location of anchor points relative to one another is also a factor in this stage of anchor system analysis. Failure of one anchor point should not result in excessive swinging of the load toward the remaining anchor point or points.

S – Solid

Choose the strongest available anchor point. If no single anchor point seems strong enough then combine multiple anchor points until you are confident your anchor system is strong enough. Build your anchor with materials at least as strong as the weakest point in your system.

T – Timely

Balance the need for strong anchors with the need to reach your patient as quickly as possible. Simpler is usually better.

Single Point Anchors

Within a Single Point Anchor, there are two types of connections:

-

Indirect for webbing, cord, and other such material.

-

Direct which uses the actual working or belay lines themselves.

Multipoint Anchors

Often, single point anchors are either non-existent or marginal, thus necessitating the need for multipoint anchor systems.

-

Rigging a backup or secondary connection to a separate anchor.

-

Available anchor points are not exactly where they need to be.

-

A directional shift is possible during the evolution

Four Types of Multipoint Anchor Systems:

-

Slack Anchors Systems: These are non-tensioned systems are more for backups.

-

Tensioned Anchor Systems: These utilize some form of tensioned mechanical advantage rope system between anchor points. PreTensioned back-ties, non-working 3:1 MAs, AZTEKS, Munter Mule are examples.

-

Load Sharing Anchor Systems.

-

Load Distributing Systems.

Shared & Distributive Anchors (Specified Multipoint Anchors)

Load Sharing Anchors (LSA) are theoretic in the distributive attributes. They’re clean and generally efficient. The point of disproportion happens at the point when a load shifts and the anchors won’t accomodate and safe transition between the two anchors. This could result in a slacked line, and this is not what this anchor system is intended for. So if there is ever concern where the load could shift, don’t use an LSA, but rather something more accomodating. That said LSAs are the preferred Multipoint Anchor. They cleaner, faster, non-extending, safer and have a greater operational application that LDAs.

Load Distributing Anchors (LDA) are similar to its Load Sharing cousin, but differ at three points:

-

A single piece of material to connect anchor points.

-

Will theoretically distribute the load when a shift does occur.

-

Should an anchor point fail, redistribution still remains.

Extensions, Back-Ties & Redirects

As with all anchor systems, making sure extension, back-ties, and redirects meet all the criteria of EARNEST.

What does this stand for? Equalize your anchors so they are always in tension. Angles are minimum. Redundant. Never Extending if failure occurs, and Strong. Timeliness is important but better correct than hastily done and wrong.

Theory of Anchors

Anchors are the most critical component of any rope rescue system. The entire rescue is in jeopardy if the anchors are not reliable. Anchor systems are made up of two major elements:

-

Choosing the best anchor (i.e. boulders, vehicles, trees, and bolts), and

-

Rigging the anchor

Peace on your days…

Lance

4,070 thoughts on “Anchors: The Underpinning of Everything That Has a System Attached to It”

978268 22154Im agitated all these write-up directories. It confident would be good to have every post directory that instantly accepts articles. 207213

Pretty! This was a really wonderful post. Thank you for your provided information.

Saved as a favorite, I really like your blog!

Great wordpress blog here.. It’s hard to find quality writing like yours these days. I really appreciate people like you! take care

how to get accutane without prescription

clindamycin 150 mg tablet

canadian pharmacy world coupon

advair buy online

buy amoxil without prescription

can i buy amoxicillin over the counter in mexico

albendazole over the counter canada

[url=http://buysynthroid.shop/]synthroid 088 mg[/url]

metformin online pharmacy

order zoloft online no prescription

best price for levitra

generic for effexor xr

clonidine pills

diflucan 150 mg medication

augmentin 375

16 albuterol

accutane pills

valacyclovir valtrex

orlistat 120 mg buy uk

synthroid 25 mcg

inderal 120

buy fildena

darknet drug store darkmarket

dark market url dark market 2022

darknet market lists darkmarkets

deep web drug links deep web drug url

deep web drug url tor dark web

dark web market list tor markets links

best darknet markets bitcoin dark web

darknet drug market dark web market

dark web market list tor markets 2022

dark web links tor markets 2022

dark web markets dark web sites

tor darknet darknet drug links

darknet drug links darknet drug market

tor markets 2022 darknet drug links

darknet drug links darknet websites

darkmarket url dark market link

darknet market links tor markets 2022

darknet market lists tor dark web

tor markets links deep web drug markets

dark market dark web link

dark web market list drug markets dark web

darknet market darknet drug market

darkmarket url deep web drug markets

darknet websites dark web drug marketplace

best darknet markets dark market list

darknet market links tor marketplace

deep web markets dark markets

dark web sites dark market onion

darkmarket deep web drug markets

deep web drug store tor market url

darknet websites darknet markets

onion market deep web drug store

darknet drug store dark web sites

darknet drug store darkweb marketplace

darknet drug market darkmarket link

tor market links dark web links

tor markets links dark web drug marketplace

dark web sites darkmarket list

dark market list onion market

tor markets links darknet market lists

dark market 2022 dark market 2022

darknet marketplace bitcoin dark web

tor markets links dark market 2022

dark web sites dark markets 2022

tor dark web dark markets 2022

deep web drug markets tor market url

dark web market list deep web drug url

dark web market onion market

augmentin no prescription

deep web markets dark market 2022

tor darknet tor market url

darkmarket 2022 dark web links

dark market dark markets 2022

darknet marketplace dark market onion

tor marketplace tor markets links

darknet drug market darknet drug store

tor market darknet drug store

dark market list dark markets

darkmarket list darkmarket 2022

best darknet markets tor markets

dark markets dark web drug marketplace

darknet drug store dark web market

dark web market links dark market list

darkmarket link tor markets links

dark web market links dark market list

tor markets 2022 tor markets 2022

tor market url darkmarket url

darkweb marketplace drug markets dark web

[url=https://buybaclofen.shop/]baclofen purchase[/url]

darknet market list dark market list

darkmarket url dark markets 2022

tor market links deep web drug links

deep web drug store darkmarket

deep web drug store tor darknet

drug markets onion dark web links

darknet marketplace darknet drug links

dark web market tor market url

darkmarket 2022 tor darknet

dark web market links deep web drug store

dark web drug marketplace tor dark web

deep web drug store darknet drug store

dark web drug marketplace darkweb marketplace

dark market onion darknet drug links

tor markets 2022 darkmarket 2022

dark web sites darkmarket list

tor market url drug markets dark web

tor markets deep web drug url

darkmarket 2022 darknet drug market

tor marketplace darkmarket list

darknet market list dark market url

tor darknet dark market onion

onion market dark markets

dark market list onion market

tor markets 2022 darknet market links

dark market url dark web drug marketplace

dark market tor darknet

darknet market links tor markets

drug markets dark web darknet drug store

darknet drug links darknet marketplace

darkmarket url best darknet markets

drug markets dark web dark web links

darkmarket link darkmarket link

dark market link darkweb marketplace

dark market 2022 darknet market lists

tor market url dark market url

darknet marketplace tor darknet

deep web drug store dark web drug marketplace

dark market 2022 tor markets

darknet markets dark web market list

dark web markets darkmarket 2022

deep web drug links drug markets onion

tor market tor darknet

best darknet markets darknet market list

darkweb marketplace deep web drug store

dark market url dark web market

darkmarkets darknet market

tor market darknet market lists

dark market 2022 dark markets

dark markets 2022 drug markets dark web

tor markets links onion market

tor market darkmarket list

dark market url darknet drug store

tor markets links darkmarket link

darknet drug links dark web market

dark web market links drug markets onion

deep web drug store dark web market

dark web markets dark web market list

deep web drug links deep web drug markets

deep web drug markets dark web market

dark web market links tor darknet

dark market list dark web drug marketplace

darknet market lists tor markets links

darknet drug links darkmarket 2022

tor markets darknet drug market

deep web drug url darknet drug market

deep web markets dark web drug marketplace

darknet market list darknet websites

deep web markets tor marketplace

darkmarket 2022 darkmarket link

dark web markets darkmarket

tor markets links darknet websites

darknet drug market darknet marketplace

dark web market links tor marketplace

darknet drug store darkmarket 2022

deep web drug links darkmarkets

tor darknet dark web market

onion market darknet drug links

dark web market links darkmarket link

dark web market darknet websites

dark market list dark market url

darknet market list dark market list

dark market url deep web markets

drug markets dark web dark web market list

darkweb marketplace darkmarket

deep web drug markets darkmarket

darknet drug store darknet markets

darkmarket 2022 darknet market lists

darkmarket url dark market list

dark market list drug markets dark web

darknet marketplace darknet drug market

deep web drug links deep web drug store

tor darknet deep web markets

dark web link dark web markets

darkmarkets deep web drug url

deep web drug links bitcoin dark web

deep web drug store deep web drug links

darknet websites dark market onion

darkweb marketplace tor darknet

tor market tor market

deep web drug links darknet markets

tor market darknet market

darkmarket link darkmarket list

dark web market list dark market url

dark web market list darknet market lists

tor markets links dark web market list

bitcoin dark web dark market link

darknet market lists dark markets

tor market darkweb marketplace

tor markets 2022 dark web market

deep web drug markets dark markets

deep web markets tor marketplace

dark market darknet market list

dark web market links dark web drug marketplace

darkmarket dark web market list

dark markets dark web market list

darkmarkets darkmarket 2022

dark markets tor marketplace

darknet websites drug markets onion

darknet drug links deep web drug store

dark web sites drug markets onion

darknet markets best darknet markets

darkmarket link deep web drug markets

dark web link dark web link

dark web market tor markets links

dark web drug marketplace darkmarket

tor marketplace darkmarket list

darknet drug links darknet market links

darkmarket 2022 darkmarket url

darknet market links darkmarket 2022

tor market url tor markets 2022

darknet market tor market

tor darknet darknet websites

tor darknet darknet market list

darknet market darkmarket list

tor dark web dark markets 2022

deep web markets dark market url

tor darknet dark market url

dark market list dark web sites

dark markets tor markets links

tor markets darkmarket 2022

darknet websites darknet market list

deep web drug url deep web drug markets

deep web drug links dark market 2022

darkweb marketplace darkmarket url

darknet market links dark market list

darknet market lists darknet drug links

dark market list dark markets 2022

darkmarket link darkmarkets

darkweb marketplace tor markets

deep web drug markets dark markets

drug markets dark web drug markets dark web

dark web market list darknet drug store

dark markets 2022 dark markets

darkmarket dark web sites

tor markets links darknet market

darkmarket link deep web drug markets

darknet drug store tor markets 2022

darknet drug links dark market url

darkmarket url dark market link

darkmarket list onion market

dark market onion drug markets onion

darkmarket dark web drug marketplace

deep web drug markets darknet market list

darkmarket link darknet marketplace

darkmarket tor market url

deep web drug url deep web drug url

tor market dark market

dark web link darknet market links

dark markets darkmarket link

darknet drug links darknet market lists

darknet market list tor market

darkmarket list dark market list

dark market url deep web drug url

dark web links darknet market list

deep web drug links tor markets

dark market list onion market

dark market url dark web market

deep web drug links deep web drug url

darknet websites deep web markets

darknet markets drug markets onion

deep web drug url deep web drug store

dark web market links tor market url

tor markets links dark web market

deep web drug markets tor markets 2022

darkmarket link darkmarket link

darkmarket list darknet marketplace

dark markets deep web drug url

dark web market list onion market

tor marketplace darknet market

darkmarket dark web links

dark market list dark web markets

drug markets dark web dark web link

darkmarket darkmarket url

deep web drug url darknet market lists

darknet marketplace tor markets 2022

dark web drug marketplace darkmarket link

tor marketplace tor markets links

darkweb marketplace best darknet markets

darkmarket link darkmarket 2022

deep web drug url dark market url

tor marketplace darkmarkets

tor markets 2022 darknet market lists

darkmarket 2022 deep web drug store

darkmarket list deep web drug links

tor market darknet drug market

dark market list darkmarket url

dark market link dark market link

bitcoin dark web darkmarket link

tor market darknet markets

drug markets onion darknet websites

tor dark web deep web markets

drug markets onion darknet market lists

tor darknet deep web markets

dark market 2022 tor marketplace

deep web drug markets darkweb marketplace

darknet market list dark web drug marketplace

dark web sites darkmarket 2022

dark market 2022 tor market url

darknet marketplace drug markets dark web

tor market url dark web markets

darknet market list drug markets onion

darknet drug market tor markets

darkmarket list bitcoin dark web

dark market list best darknet markets

darknet marketplace tor market links

darkmarket url dark web market list

deep web drug links darknet market lists

deep web drug links deep web drug markets

darknet marketplace darkmarket

deep web drug markets dark web drug marketplace

dark market list dark web drug marketplace

tor markets links dark web markets

tor marketplace drug markets onion

dark market onion darknet market

darkmarket link darkmarket

darknet markets best darknet markets

darknet markets drug markets onion

tor market darkmarkets

drug markets onion best darknet markets

darkmarket url dark market list

dark market list dark markets

darknet market list deep web drug store

darknet marketplace dark web market links

deep web drug links bitcoin dark web

darknet market lists tor market url

dark web market drug markets onion

dark web links dark web sites

deep web drug links deep web drug store

dark web sites dark web market list

deep web drug links dark web drug marketplace

darknet market lists deep web drug links

deep web drug url tor markets

darknet market links dark market

dark market list darkmarket

darknet markets tor dark web

dark web link darkmarket list

dark web links dark web market links

dark market onion dark web market

deep web drug links bitcoin dark web

deep web drug links drug markets dark web

darknet marketplace darkmarket list

dark market onion tor markets 2022

darkmarket list dark markets

dark market 2022 dark web market list

dark web links dark market list

deep web drug links drug markets onion

dark web market dark web sites

darknet drug links onion market

tor markets darkmarket url

tor markets deep web drug links

deep web drug links darknet market

dark web markets deep web drug store

darknet drug market dark web link

tor markets links darkmarket link

darknet websites darknet market list

tor market links best darknet markets

dark web market list dark market list

dark market 2022 tor markets links

dark market deep web drug markets

darknet drug store darknet market links

dark market 2022 darkmarket

darkmarket url darkmarket list

darknet marketplace dark web market list

darknet market links dark market 2022

dark market link dark web market

darkmarket url darkmarket list

darknet drug market best darknet markets

darknet drug store dark market

darkmarket link bitcoin dark web

dark market url dark market

darknet drug market tor markets

dark web link deep web markets

darknet drug market dark web markets

darknet drug store dark web drug marketplace

dark web drug marketplace tor markets links

dark market onion market

darkmarket url darkweb marketplace

dark market 2022 tor dark web

dark web market links dark web link

tor markets 2022 darknet market list

dark market link dark web links

darkmarket 2022 deep web drug url

darknet drug store tor market links

dark market url dark web sites

darkmarket 2022 tor markets links

darknet websites darkmarkets

deep web drug markets darknet drug market

dark market link deep web drug markets

dark market url dark markets 2022

tor market links tor market url

best darknet markets bitcoin dark web

darknet drug market drug markets onion

darknet drug market tor markets 2022

darknet drug store dark web link

darkmarket darknet market lists

tor marketplace darkmarket 2022

darknet market lists dark markets 2022

dark market link dark web link

dark market url darkweb marketplace

dark web sites deep web markets

drug markets onion dark markets

darkmarkets darkmarket url

deep web drug url dark web sites

darknet market links drug markets onion

dark web market tor market

dark web link deep web drug links

tor market links tor marketplace

bitcoin dark web deep web drug markets

dark market link tor marketplace

best darknet markets darkweb marketplace

dark web market list dark web market links

onion market dark web markets

dark web sites darknet markets

darknet marketplace dark web markets

darkmarket url dark market onion

darkmarket 2022 dark web drug marketplace

darknet market lists bitcoin dark web

darknet market dark market onion

tor marketplace deep web markets

deep web drug links bitcoin dark web

tor market dark web sites

dark web sites dark market link

dark web link dark market url

darknet market lists darkmarket

darkmarkets drug markets onion

tor market url dark web sites

darkmarket list onion market

darknet websites darknet market links

tor dark web deep web markets

dark markets 2022 deep web drug markets

tor markets 2022 darknet market lists

tor darknet dark market url

tor darknet darknet market list

tor market links dark web market

darknet market darknet drug store

dark web markets drug markets onion

tor market url darknet market lists

darknet market list dark markets 2022

darkmarket link dark market list

darknet drug links drug markets dark web

dark web markets dark web links

drug markets dark web dark web market

deep web drug markets darkmarket

darknet drug market dark web links

darkmarket list darkmarket 2022

dark web links darknet market list

darkmarket tor darknet

darkmarkets tor marketplace

dark market list dark market 2022

tor market darknet drug store

darknet market links darknet market list

dark market url bitcoin dark web

tor markets 2022 deep web drug markets

tor marketplace deep web drug store

dark market 2022 dark web link

dark web links darknet websites

darkmarkets deep web drug links

deep web markets darkmarket 2022

darknet drug store tor marketplace

deep web drug links dark web sites

darknet drug links darknet drug store

deep web drug links tor markets 2022

darknet drug market darknet websites

darknet market links tor markets

darkmarket url deep web drug links

dark market link tor market url

dark web sites darknet market

dark markets 2022 darknet websites

darknet drug store dark web drug marketplace

dark market link dark web link

tor dark web dark market

drug markets dark web tor marketplace

tor markets links darkmarket list

darkweb marketplace dark web market list

darknet market lists tor market links

darkweb marketplace dark markets 2022

dark web sites dark web market list

tor market url darknet marketplace

dark web markets darknet marketplace

tor market url dark market

drug markets dark web darkmarket url

darknet websites dark web link

dark market dark web markets

deep web drug url deep web drug url

dark market 2022 dark market link

dark web market list darknet marketplace

darknet market links darknet drug links

dark markets dark markets

darknet markets dark web drug marketplace

tor market links best darknet markets

tor marketplace tor market links

darkweb marketplace dark market list

dark market 2022 dark market url

deep web drug store deep web drug markets

darknet market lists tor marketplace

drug markets onion darkmarkets

darkmarket link dark market url

darknet drug market tor darknet

darknet drug links dark web drug marketplace

dark markets 2022 darkmarkets

darkmarket darkmarkets

darknet websites bitcoin dark web

darknet drug store darknet market lists

darkmarkets darknet market lists

dark market list tor darknet

dark market 2022 darkmarket url

darkweb marketplace tor dark web

darknet market links tor market

tor marketplace dark markets 2022

dark markets darknet market

darknet drug store onion market

tor market url darknet websites

drug markets dark web darknet websites

drug markets onion bitcoin dark web

tor market onion market

dark web markets dark market link

darkmarket darkweb marketplace

darknet drug store drug markets onion

tor markets 2022 deep web drug markets

tor markets 2022 dark market link

tor markets links dark markets 2022

tor markets links drug markets onion

tor markets dark market

tor darknet tor market url

best darknet markets tor market url

darkmarket 2022 tor darknet

dark web link darkmarket link

darknet drug links dark web sites

tor markets 2022 darknet websites

dark market url darknet marketplace

deep web drug links darkmarket url

darknet marketplace darknet markets

dark web link drug markets onion

darknet drug market dark market 2022

dark markets darkmarket link

darknet market list tor market

best darknet markets darkmarket

dark web drug marketplace dark web links

dark web market links tor market url

deep web drug links deep web drug markets

suhagra 25 mg tablet

darkweb marketplace darknet market

deep web drug links dark market

dark markets tor markets

darkmarket url onion market

darkmarket 2022 dark market

deep web drug markets dark web links

darknet websites onion market

dark web market list darkmarket url

tor darknet deep web drug store

deep web drug url dark web sites

dark web links tor markets 2022

best darknet markets tor darknet

onion market dark markets 2022

darknet drug market dark web sites

darknet market dark web drug marketplace

darkmarkets dark markets 2022

dark market url darknet markets

tor market darknet markets

darknet drug market darknet drug links

tor markets links darkmarket url

dark web market dark web link

dark web sites onion market

deep web drug links dark web market links

dark web drug marketplace bitcoin dark web

deep web markets tor dark web

dark market onion deep web markets

darkweb marketplace tor marketplace

tor markets 2022 deep web drug markets

dark market 2022 deep web markets

onion market dark web sites

darknet market tor market

tor markets dark web market links

darkweb marketplace dark market link

deep web drug markets darknet market list

dark web links dark web markets

darknet market darkmarkets

dark web markets darknet websites

darkmarkets deep web drug url

darkmarket dark market list

darkmarket list best darknet markets

tor markets tor markets 2022

darknet market lists darknet drug links

darkmarket list darknet market links

dark market 2022 dark web drug marketplace

darkmarkets darknet markets

darknet drug market tor market url

dark market list dark market 2022

darknet drug links darknet drug market

best darknet markets dark market

tor dark web dark market

darkmarket 2022 dark market link

darkmarket list darkmarket 2022

darkmarket 2022 darknet markets

darkmarket 2022 deep web markets

dark web market tor darknet

deep web drug markets dark web sites

darkmarket list drug markets dark web

darknet marketplace tor markets

best darknet markets dark market

darknet market list darkweb marketplace

deep web drug url dark market list

dark market onion tor market links

darkmarket url darknet market

darknet market darknet drug store

darknet drug market onion market

dark web sites darkmarkets

dark markets 2022 darkmarket

tor markets darknet market links

darkmarket deep web drug markets

tor darknet tor markets

dark markets 2022 drug markets onion

tor market url darknet market

dark web drug marketplace darkmarket 2022

drug markets dark web drug markets dark web

darknet marketplace dark web links

dark market onion dark market url

dark web drug marketplace darknet drug links

darknet drug store dark web market

darknet websites darkmarket link

darknet drug market dark market onion

drug markets dark web dark market

tor market links darknet drug store

dark market tor markets 2022

deep web markets deep web drug store

darkmarket list dark market url

tor markets 2022 tor darknet

darknet websites darknet websites

darkweb marketplace tor market

drug markets dark web tor markets 2022

darkmarket link dark web link

darknet websites tor markets

dark web drug marketplace drug markets onion

tor marketplace dark markets 2022

deep web drug markets bitcoin dark web

tor marketplace drug markets dark web

drug markets onion tor market

tor market links tor market links

tor darknet dark markets

darkmarket 2022 dark market url

dark markets dark markets 2022

dark web market links darknet market list

dark web links best darknet markets

dark web drug marketplace darkmarket 2022

dark web sites darknet drug market

dark web market links deep web drug store

deep web drug links dark market onion

darkmarket url dark markets 2022

dark web market list darkmarket link

darkmarket list darkmarket url

dark web drug marketplace dark web drug marketplace

dark market url dark markets

darkmarket link dark web market

dark market 2022 best darknet markets

tor market darkmarket 2022

tor markets dark web sites

darknet drug market dark markets

darknet websites dark market link

tor market url deep web drug store

darkmarket best darknet markets

darkmarket darknet market lists

drug markets dark web dark web drug marketplace

dark web markets onion market

dark market onion dark market onion

deep web markets darknet market

tor dark web darkmarkets

darkmarket link tor markets links

darknet market tor marketplace

dark markets tor markets links

onion market tor market url

darknet drug market darkmarkets

drug markets onion darknet market lists

darknet drug store darkmarket link

best darknet markets tor markets 2022

darkmarket link dark web market links

darknet market list tor market url

dark market link dark market url

darknet market links darkmarket list

tor markets tor darknet

dark market 2022 darknet markets

drug markets dark web dark market

darknet drug store darknet market links

drug markets onion tor markets

darknet websites dark market

dark web market list darkmarket 2022

dark web market list darkmarket

onion market drug markets dark web

tor market links deep web drug store

dark markets 2022 dark market url

tor market url darknet markets

darknet marketplace dark web sites

drug markets dark web darkmarkets

best darknet markets dark market list

darknet marketplace tor market

dark market list tor dark web

dark web market deep web drug url

darknet marketplace darknet markets

tor markets drug markets dark web

dark market list darknet websites

darkmarkets deep web markets

dark web sites deep web drug store

darknet markets best darknet markets

best darknet markets darknet markets

darkmarket 2022 darkmarket list

dark market onion tor market

darkmarket 2022 darknet drug links

darkmarket url dark web links

dark market darknet drug market

darkmarket list tor market links

best darknet markets drug markets dark web

darkmarket 2022 drug markets dark web

dark web sites dark markets

onion market darkmarkets

dark market onion darknet market lists

tor market links darknet market list

tor markets links dark web market list

tor markets links tor marketplace

darknet market links darkweb marketplace

dark market 2022 dark web links

tor marketplace darknet markets

darkmarket link tor darknet

tor markets 2022 darknet drug links

darknet market list darkmarket 2022

dark web sites darknet drug market

deep web drug url dark market

dark web markets darkmarket

tor darknet darkmarket link

darknet market lists tor market links

tor markets 2022 tor marketplace

deep web drug links tor market links

deep web drug markets dark web market

darkmarket list tor market url

dark web sites tor marketplace

deep web markets tor market links

dark web markets darknet market lists

tor market url darkmarket url

darkmarket list dark markets

tor markets 2022 deep web drug markets

best darknet markets darkmarket url

dark web drug marketplace darkmarkets

dark web market links darkmarket 2022

darknet drug store tor market

tor markets links bitcoin dark web

dark markets dark market list

darknet market lists tor dark web

darkmarket 2022 deep web drug links

darknet market deep web drug markets

tor market dark web sites

darknet market lists darknet marketplace

darknet websites drug markets dark web

dark market link dark web links

darknet market list dark market

drug markets dark web tor darknet

tor market url dark web market

best darknet markets tor market

darkweb marketplace drug markets onion

darknet drug links dark market list

dark web sites dark market 2022

darkmarket link deep web drug links

dark market 2022 darkweb marketplace

tor markets links darknet marketplace

tor market tor markets 2022

dark markets darknet markets

darknet markets darknet marketplace

cozaar 25 mg

dark web market links dark web link

deep web drug markets tor darknet

tor markets 2022 deep web drug store

deep web markets deep web drug markets

darknet drug links dark market list

dark web drug marketplace deep web drug markets

bitcoin dark web deep web drug markets

dark markets dark web market links

dark web links dark market onion

darknet market list dark web links

dark markets 2022 tor market

darknet market lists darknet drug links

darkmarket dark market

darknet drug market darkmarket

darknet market lists dark market list

dark web link dark web links

bitcoin dark web deep web drug url

tor darknet darknet drug market

darknet market lists bitcoin dark web

darkmarket url dark markets 2022

darknet market links tor market links

darkmarket 2022 tor market

dark market dark web market links

best darknet markets dark web link

darkmarket darknet drug links

darknet drug store darkmarket 2022

dark web market deep web drug url

darknet websites best darknet markets

tor market darkmarket 2022

dark market 2022 darkmarket

dark web market list dark web link

dark market dark web links

darkmarket list dark market

darkmarket 2022 dark market

tor marketplace dark web market links

tor market links darknet market links

dark market tor market

darkmarket list darkweb marketplace

darknet markets tor marketplace

tor market dark web market

darknet market lists dark market

darknet drug links darkmarkets

onion market deep web drug markets

darkmarkets dark market url

dark market darknet drug store

dark markets 2022 deep web markets

dark web market links darknet market lists

dark markets 2022 drug markets dark web

deep web markets darknet drug links

dark web market links drug markets onion

dark market url deep web drug markets

tor markets links darknet drug market

darkmarket url dark market onion

dark market 2022 dark web links

drug markets onion tor marketplace

darkweb marketplace tor marketplace

deep web markets bitcoin dark web

darknet websites darkmarkets

dark markets 2022 darknet market lists

dark market url deep web drug store

dark market darknet drug store

dark market link dark market onion

dark market url dark market url

tor markets 2022 darkmarkets

500 mg indocin

darknet marketplace deep web markets

tor market darkmarket link

drug markets dark web deep web drug store

deep web drug store dark market onion

drug markets dark web darkmarket list

dark markets dark market

onion market drug markets dark web

dark web links bitcoin dark web

tor market dark market

darknet market onion market

dark web market dark market link

darknet drug market darkweb marketplace

drug markets onion tor marketplace

deep web markets tor markets 2022

darkmarket dark market

deep web markets drug markets dark web

dark web markets darkmarkets

dark market url darknet market

tor market url darkmarket list

tor market url deep web markets

darknet markets drug markets dark web

dark markets 2022 dark web links

tor markets darkmarket 2022

darknet market links deep web drug links

tor markets darknet marketplace

darknet websites darknet websites

dark market list drug markets dark web

darkmarket list dark market list

dark web link darkmarket 2022

deep web markets dark market list

deep web drug links dark web links

best darknet markets tor market

onion market darkmarket 2022

darkmarket 2022 darkmarket link

darkmarket 2022 darknet markets

onion market dark markets 2022

darkmarket 2022 darknet market links

darknet market lists dark web markets

darknet drug market deep web drug store

darknet drug market dark market onion

darknet market drug markets dark web

tor marketplace dark markets

darknet market lists dark web market

deep web drug store dark web sites

dark web market list darknet drug store

dark web links darknet market lists

dark market url dark web sites

dark web links dark web link

tor market links darkmarkets

darkmarket link tor market

deep web drug store dark market 2022

deep web markets dark web link

darknet drug market tor markets links

tor dark web deep web drug links

dark market 2022 dark web sites

tor markets dark web market

darkmarket bitcoin dark web

darknet marketplace tor markets links

deep web drug store dark markets

dark market onion dark market list

drug markets onion tor marketplace

tor dark web darknet marketplace

dark web market links darknet drug links

darknet drug market darkmarket url

deep web drug markets dark web market

darkweb marketplace dark web market

darknet market lists darkmarket url

dark market onion darkmarket link

darknet websites darknet websites

dark web drug marketplace deep web drug store

darknet market deep web markets

dark web market list deep web drug links

dark markets dark market

darknet websites onion market

deep web markets darknet market lists

tor darknet darknet drug market

dark web sites dark web sites

darkmarket link dark web market list

darkmarkets dark market

tor market links darknet market links

dark markets 2022 dark web market links

darkmarkets darknet markets

tor markets links dark market 2022

tor markets 2022 tor market links

darknet market links darkmarket 2022

tor market darknet drug market

tor market url deep web drug markets

dark web sites deep web drug store

tor market url dark web market list

onion market dark web sites

dark web drug marketplace darkmarket

darknet websites darkmarket list

deep web drug links dark web link

dark market link dark market list

drug markets dark web best darknet markets

darkmarket url deep web drug store

darkmarket list dark markets

darkmarket list dark market 2022

darkmarket 2022 tor market

darknet market darknet drug store

dark web link dark market url

dark web market dark web market links

darkmarkets darknet drug market

darknet drug links darknet market lists

tor market dark web market

deep web drug url tor darknet

tor markets darkmarket link

dark web market list dark web market list

tor darknet drug markets onion

dark web market darknet market

dark market link drug markets dark web

dark market darknet market

dark web market links tor markets

darkweb marketplace tor markets links

tor dark web darkmarket link

darknet markets deep web drug store

darknet drug store dark web markets

dark web link bitcoin dark web

darknet marketplace deep web drug links

dark market list darkmarket url

bitcoin dark web onion market

dark web drug marketplace darknet market links

tor markets 2022 tor dark web

darknet drug store dark web links

darknet websites darknet websites

deep web markets deep web drug store

darkmarket link deep web drug markets

tor marketplace tor marketplace

dark market list dark market

darkmarket url dark web market list

darknet markets dark market

deep web drug store darkmarket link

deep web drug store dark web links

dark market darknet drug links

dark markets 2022 darknet market list

darknet market links tor darknet

darknet marketplace deep web drug store

deep web drug links dark market list

dark web links onion market

darknet marketplace dark market link

tor markets links bitcoin dark web

darkmarket darknet markets

tor markets darkmarket link

dark web markets darknet drug store

darknet websites tor darknet

diflucan canada

darkmarket url darkmarket 2022

deep web drug markets dark web link

dark market list darkmarket 2022

dark web sites darknet websites

dark web sites dark web market

dark web market list dark web links

dark markets 2022 dark web markets

dark market list dark market link

tor darknet darknet market links

darkweb marketplace best darknet markets

dark market url dark web drug marketplace

darkmarket url dark web markets

darkweb marketplace tor market links

dark web markets darknet drug store

tor dark web tor marketplace

dark web link dark web markets

darkmarkets darkmarkets

drug markets dark web darknet market lists

tor market links dark web market links

dark web market list dark web market

deep web drug url dark web links

dark market onion drug markets onion

dark web market list dark web sites

dark web link tor market links

best darknet markets dark web drug marketplace

tor market url dark market url

deep web drug markets dark web link

dark markets 2022 dark market

darknet markets dark web link

darkmarket url dark markets

tor marketplace deep web drug links

tor dark web best darknet markets

darkmarket link darkmarket

dark market url drug markets dark web

darknet market links dark market

deep web drug url darkmarket list

deep web drug store dark web market list

darknet market lists tor dark web

dark market url tor markets links

dark web sites darknet market lists

dark web markets dark web market

dark web drug marketplace dark market link

drug markets onion deep web drug url

dark web markets darknet market list

darknet drug market darknet market links

deep web markets darknet markets

dark web markets darknet marketplace

dark web market links dark markets 2022

darknet drug links best darknet markets

drug markets onion tor dark web

darknet market links dark web market links

304364 104271There is noticeably a bundle to realize about this. I assume you created various good points in capabilities also. 492068

dark markets tor dark web

drug markets onion dark web drug marketplace

tor market darknet drug market

darkmarket list darknet websites

darkmarket url deep web drug links

tor markets darkmarket 2022

bitcoin dark web darkmarket url

dark web market darkmarket 2022

dark markets dark market link

darkmarket tor dark web

darknet drug links darknet market

deep web drug links dark web sites

darknet market list darknet market links

tor dark web deep web drug markets

darkweb marketplace dark market list

dark web sites darkweb marketplace

darknet market lists deep web markets

best darknet markets tor market

darkmarket list darkmarket

darknet market list dark web market

darknet market lists drug markets dark web

darknet marketplace tor market url

darkweb marketplace deep web drug links

darkmarket list dark market

darkmarket 2022 tor market url

dark web market links deep web drug markets

tor marketplace darknet marketplace

tor markets links dark markets 2022

dark web links tor markets

dark web drug marketplace darknet drug store

darknet websites deep web drug store

dark market link darknet market lists

dark market link tor dark web

darkmarket deep web markets

dark market onion dark markets 2022

dark markets dark markets

dark market url dark markets 2022

darknet markets tor markets 2022

dark web links darknet markets

tor darknet bitcoin dark web

dark market 2022 darkmarket 2022

dark market link dark web market

tor market darknet drug store

dark web market list drug markets dark web

tor markets 2022 dark market url

darknet drug links dark web link

tor markets links dark market url

deep web drug markets darknet market

tor marketplace dark markets

tor markets links darknet drug store

dark markets dark web sites

tor marketplace darknet websites

darknet market bitcoin dark web

deep web drug url dark web links

tor marketplace darkmarket 2022

darknet market tor market

best darknet markets darkmarkets

bitcoin dark web dark market link

deep web markets dark web drug marketplace

darkmarket url darknet market

deep web drug url darkmarket

tor markets dark market onion

dark market onion dark market onion

darkmarket list dark market onion

dark web link tor markets 2022

dark markets dark market onion

dark markets darknet market

tor market url darkweb marketplace

darknet drug market tor markets 2022

darknet drug store deep web drug url

darkmarket link dark web drug marketplace

dark market darknet drug market

dark market url dark web market links

dark market list dark market url

darknet markets darkmarkets

darknet marketplace darkmarkets

darknet market lists darknet market list

darknet drug links best darknet markets

darknet drug market darknet market lists

best darknet markets darknet drug market

bitcoin dark web onion market

onion market tor markets links

deep web drug markets darknet drug store

darkmarket list darknet drug links

darknet websites bitcoin dark web

dark web market links dark web market links

drug markets dark web deep web drug store

tor darknet dark web market

deep web drug url darkmarket url

bitcoin dark web tor markets

darknet market lists dark web market links

deep web drug store tor darknet

tor darknet bitcoin dark web

tor marketplace darknet market

dark web drug marketplace darknet marketplace

onion market dark market

tor market url dark web market list

darkmarket link dark market

darknet marketplace tor darknet

darkmarket 2022 darkmarket 2022

tor darknet dark web link

darknet market lists dark market

dark market onion tor market links

deep web drug links dark web market list

dark market url dark market onion

deep web drug url darknet drug store

tor markets 2022 dark web drug marketplace

tor markets darknet drug store

dark markets darkmarkets

tor market bitcoin dark web

deep web drug store tor darknet

onion market darkmarket url

tor markets links tor marketplace

tor market darkweb marketplace

tor markets links dark web link

onion market dark market 2022

darknet drug market dark market 2022

darkmarket link drug markets dark web

tor marketplace dark web market links

tor dark web dark web market

dark market list darknet markets

dark market onion darknet markets

dark web market links darkweb marketplace

tor marketplace dark market list

dark market 2022 darknet market

dark market onion dark market link

dark web markets tor markets

darknet marketplace dark market list

darknet websites darknet drug store

dark markets tor markets links

dark markets dark web markets

tor market url tor markets links

drug markets dark web onion market

deep web drug store tor market

darkmarket 2022 bitcoin dark web

darknet drug links darkweb marketplace

tor market darkmarket link

darknet market lists dark market list

dark web markets darkmarket

dark market url darknet drug store

darknet market darkmarkets

darknet websites drug markets onion

dark web market links deep web drug store

dark market onion tor darknet

darknet drug store darknet markets

dark market darknet drug market

darknet market links deep web drug markets

dark web drug marketplace best darknet markets

darknet market links dark web market

darknet websites darknet market lists

dark web sites dark web sites

darkmarket list drug markets onion

tor markets 2022 tor market url

dark market 2022 dark market onion

dark markets 2022 onion market

best darknet markets darkmarket link

darkweb marketplace deep web drug links

deep web drug url dark market list

best darknet markets darkmarket list

darkmarkets darkmarket

dark market url tor markets 2022

darknet marketplace deep web drug store

darkmarket 2022 darkmarket link

darkmarket url dark market onion

dark market onion dark markets 2022

bitcoin dark web deep web drug store

darknet drug links dark markets

deep web drug markets dark markets

darknet market links dark web market links

deep web drug links deep web drug links

dark web link darkweb marketplace

tor darknet darkmarket url

darknet market list tor darknet

onion market deep web drug store

darknet market links tor markets 2022

tor markets dark market

dark market deep web markets

dark web markets dark web link

darknet websites darknet market

dark web market links tor darknet

tor market links darknet market lists

darkmarket list dark web markets

tor dark web darknet drug links

dark web market links darkmarket list

dark web drug marketplace deep web drug markets

dark web market list tor market links

onion market darknet drug store

dark web market list dark web market

darkmarkets tor darknet

tor marketplace onion market

deep web drug links best darknet markets

darknet market lists tor market links

darkmarket list darkmarket link

deep web drug markets drug markets dark web

dark markets deep web drug links

darknet market links tor market

dark web market best darknet markets

deep web drug links darknet market links

darknet markets dark markets

darkmarkets deep web markets

tor marketplace tor market url

bitcoin dark web darknet drug store

tor dark web dark market onion

darkmarkets tor marketplace

onion market tor market

darkmarket link dark market

dark market onion drug markets dark web

darknet websites darkweb marketplace

best darknet markets dark market list

dark web market list darknet marketplace

darkmarkets dark market onion

darkmarket link best darknet markets

tor dark web dark web market links

dark markets drug markets dark web

tor market links darknet marketplace

deep web drug links darknet drug market

darkmarket url darknet markets

darknet market links deep web drug links

bitcoin dark web darkmarket 2022

onion market tor marketplace

tor markets links dark market link

dark market 2022 onion market

darknet market dark web market

tor market links dark web markets

deep web drug store dark markets

darkmarket onion market

darkmarket 2022 dark market onion

darknet drug market dark market onion

darkmarket dark market

darkmarket link tor market url

dark web markets tor market links

darknet websites dark web sites

inderal otc

dark markets tor marketplace

darkmarket link tor market

dark market onion darknet markets

dark web links tor market

darknet market links darknet market lists

darkmarket 2022 darknet market links

dark market onion tor market url

drug markets onion dark market link

darkmarkets dark market url

deep web drug url darknet websites

darkmarket link dark market list

tor markets darkmarkets

darkmarket tor market

tor market tor markets links

deep web drug store dark markets

tor markets 2022 dark market onion

darkmarket deep web markets

dark web drug marketplace dark markets 2022

dark web drug marketplace dark web market list

darknet market lists darkmarkets

tor darknet tor marketplace

darkmarket list tor markets

darknet drug links darknet marketplace

onion market dark market list

deep web drug url tor markets links

darknet marketplace darknet market list

deep web drug store dark web link

drug markets dark web deep web drug links

dark web link tor markets links

best darknet markets darkmarket

darkmarket drug markets onion

dark web markets darkmarkets

darknet market list darkmarket 2022

darknet drug links deep web drug links

dark market dark web market

darknet drug market tor markets links

darkmarkets darkmarket link

onion market darknet drug links

darknet drug links dark web markets

tor markets 2022 darkweb marketplace

darkmarket url deep web drug url

darkweb marketplace onion market

dark markets 2022 dark web drug marketplace

darknet market links tor darknet

bitcoin dark web drug markets dark web

bitcoin dark web dark market link

onion market tor market url

dark market deep web drug markets

tor markets bitcoin dark web

tor darknet drug markets dark web

atarax for itching

tor market url tor market

tor markets 2022 dark market link

dark web drug marketplace tor marketplace

tor marketplace darkmarket link

dark market link tor market url

dark market 2022 darkmarket list

bitcoin dark web deep web markets

drug markets dark web darkmarkets

dark web market links dark market link

darknet drug market deep web drug store

drug markets dark web darknet marketplace

tor marketplace darknet marketplace

darkmarket url tor market links

darknet market links darkmarket list

darknet drug links deep web drug markets

dark market onion darkmarket link

tor markets 2022 darkmarket url

darknet market lists dark market onion

dark web markets tor market links

dark web market list dark web market links

darkmarket tor dark web

dark market tor dark web

darkmarket link tor marketplace

deep web drug url darknet drug store

dark market darknet marketplace

darkmarkets dark market list

darknet market list darknet market list

tor markets 2022 tor market links

darknet drug links darknet marketplace

deep web drug store dark web markets

dark market list drug markets onion

dark web links darknet market

tor market url darknet drug links

dark market list darknet drug links

dark web link darknet marketplace

dark market darkmarket 2022

tor marketplace dark markets 2022

darkweb marketplace bitcoin dark web

dark market url darknet market list

dark web market links deep web drug store

deep web drug markets bitcoin dark web

dark web link bitcoin dark web

darknet drug links darkmarket 2022

deep web markets darkmarket url

dark market list tor markets 2022

drug markets onion darknet marketplace

dark web market darknet market

darkmarket 2022 darknet market links

dark web sites darkmarket list

dark web sites darkmarket link

dark market url tor market links

onion market onion market

dark web sites dark market url

deep web drug markets dark market list

tor markets deep web drug url

darknet drug market deep web drug markets

tor marketplace darkmarkets

tor market dark market url

dark web links darkmarket 2022

tor dark web dark market list

tor dark web dark market list

dark web link dark market url

darkmarket darknet drug store

tor market url darknet websites

tor market darkmarket

darknet drug market darkmarket list

tor market url dark market onion

dark web markets deep web drug markets

dark web link darknet drug market

dark web market darknet marketplace

best darknet markets dark market url

deep web drug store darkmarket

dark market onion dark market onion

darknet market lists darkmarket

tor dark web darkweb marketplace

dark web link darknet drug store

deep web drug store tor market links

tor darknet tor darknet

dark market url dark web links

dark web market list best darknet markets

darknet drug store onion market

darkmarket 2022 darknet market links

dark web sites dark web links

tor markets 2022 deep web drug url

best darknet markets tor markets 2022

bitcoin dark web darkmarket link

darkmarket darkmarket url

darkmarket 2022 dark market onion

dark web market list dark market onion

dark web drug marketplace darkmarket link

dark market url dark market onion

dark market url dark markets

drug markets onion darkmarket

darkweb marketplace bitcoin dark web

dark web link dark web sites

dark web drug marketplace darkmarkets

darknet market lists deep web drug store

tor market links deep web drug url

dark market 2022 dark web link

dark web markets deep web drug links

dark markets 2022 dark market link

dark web drug marketplace dark market list

darknet market links darknet markets

deep web drug markets drug markets dark web

dark market darknet drug links

dark web link deep web drug links

dark web market list dark market

darkmarket 2022 darknet market lists

dark market list darknet markets

darkmarkets darkmarket

tor market url darkmarket list

dark web markets tor markets

darkmarket list drug markets dark web

darknet market lists darknet websites

drug markets dark web tor markets 2022

dark market url darkmarket 2022

deep web markets tor darknet

drug markets dark web tor markets

darkmarket drug markets dark web

deep web drug url darknet marketplace

darknet market deep web drug markets

dark market onion dark market link

deep web drug links dark web link

tor market darkmarkets

darknet market list darkmarket 2022

drug markets onion deep web drug markets

tor darknet tor darknet

tor dark web dark market url

darknet market links dark market url

drug markets dark web dark web links

dark web link tor dark web

bitcoin dark web dark web link

dark web drug marketplace drug markets onion

dark web sites tor market url

tor markets tor darknet

dark market url darknet marketplace

bitcoin dark web tor market

deep web drug links drug markets onion

tor markets links dark market link

dark web market dark web links

darkmarket list dark web markets

onion market dark market

tor dark web darknet market links

tor darknet deep web drug links

darkmarket link dark web markets

tor markets dark web links

onion market tor markets 2022

dark web drug marketplace darkmarket

tor markets 2022 tor markets 2022

dark markets dark market onion

darknet drug store deep web drug url

dark web market links dark web market

dark web drug marketplace dark web sites

dark market list drug markets onion

tor marketplace deep web drug markets

dark web market links dark market list

deep web drug links deep web drug links

darkmarket url darkmarket link

tor darknet dark markets

tor market darkmarket list

dark markets darknet market links

dark web market links tor markets links

tor market links darkmarket url

darknet websites deep web drug store

tor darknet tor dark web

dark web sites onion market

dark web links dark web sites

darknet drug links tor market links

dark web market list dark web market list

darkmarket link dark markets 2022

darknet market darkmarket url

dark market link dark web sites

dark web drug marketplace darknet websites

drug markets dark web dark market link

tor markets 2022 darknet market links

darknet drug store dark web links

darknet market dark web link

deep web markets darknet drug store

darknet drug links dark web market links

dark web sites dark web market links

dark market url tor market links

onion market darknet market links

tor darknet dark markets

darknet market lists tor darknet

tor market darkmarkets

dark market list onion market

darkmarket list tor marketplace

darknet drug store deep web drug store

dark web links darknet market list

tor markets dark web link

darkmarket url best darknet markets

dark market darkmarket list

darknet markets darknet drug store

deep web drug markets dark web market

deep web drug markets dark web link

dark market list best darknet markets

bitcoin dark web darknet market links

drug markets dark web darknet market links

onion market darkmarket list

tor market darkweb marketplace

darknet market dark market list

darknet market deep web drug store

darkweb marketplace darknet drug store

dark web market links darkmarket list

deep web drug markets darknet drug market

dark web links darkmarket list

dark market url dark market 2022

darknet market list dark market

dark market dark market onion

dark web market links dark web market links

tor marketplace deep web drug store

darknet drug market tor market url

dark market link darknet drug links

tor markets links dark market list

dark web links darkmarket url

darknet marketplace darkmarket url

drug markets dark web bitcoin dark web

drug markets dark web darkmarket list

bitcoin dark web darknet websites

darkmarket list darkmarket url

deep web drug store tor market links

tor marketplace darknet market

dark markets 2022 darkmarkets

darknet drug store dark web market

deep web drug url dark markets

tor marketplace darknet market lists

dark web link darknet market links

deep web drug url darkmarket link

darknet drug store darknet marketplace

darknet drug links best darknet markets

tor markets 2022 deep web drug markets

dark web link deep web drug markets

darkmarket link dark market

darknet market links darknet marketplace

darknet market list tor marketplace

dark web market links tor markets links

darknet market links tor marketplace

deep web drug markets dark market link

tor markets 2022 tor market links

tor markets darknet market list

dark web link drug markets onion

darkmarket 2022 bitcoin dark web

darknet market dark markets

tor market url dark markets

dark market dark markets 2022

darkmarket tor market links

darknet websites bitcoin dark web

darknet drug store onion market

tor markets 2022 darknet marketplace

darknet drug links dark markets 2022

dark web links deep web drug links

dark web market links drug markets onion

darkmarket 2022 tor dark web

darknet market links tor markets links

dark web sites tor market url

darkweb marketplace dark market list

dark market onion dark web link

drug markets onion dark web market

dark web link drug markets onion

tor market links dark market 2022

dark web links darknet markets

darknet market lists dark web sites

darknet marketplace darknet market lists

dark web market links dark web link

darknet websites deep web drug markets

dark market onion deep web drug store

deep web drug links dark market link

tor markets 2022 drug markets dark web

bitcoin dark web dark market link

darknet market list deep web drug url

darknet markets tor markets

tor marketplace dark markets

drug markets onion tor markets

darknet market dark web sites

dark market link deep web markets

tor markets dark markets

tor marketplace tor markets 2022

darkmarket link darknet market

darkmarket url tor markets links

darkmarkets deep web drug store

darknet drug market dark market link

tor markets 2022 darknet drug store

deep web drug store dark web link

dark markets 2022 tor markets

tor market dark markets

dark web market deep web markets

dark market url dark markets

darknet market list dark market onion

tor market url darkmarkets

dark web markets deep web drug url

dark web market tor markets 2022

darknet marketplace dark market link

deep web drug markets deep web drug links

darknet marketplace dark market url

tor markets darknet market lists

darknet marketplace dark market onion

darkweb marketplace darkmarket list

darkweb marketplace tor market url

deep web drug url darkmarket

darknet drug store dark web drug marketplace

deep web drug store onion market

dark web sites dark market 2022

darknet websites dark market url

darknet market links darkmarket

dark market 2022 dark market

bitcoin dark web darkmarket list

tor marketplace darknet drug store

deep web drug links dark web market links

darknet drug market darknet drug market

tor markets links onion market

dark markets 2022 tor market url

darkmarket link darkmarket url

darknet market tor marketplace

dark market dark markets

deep web drug markets dark market list

dark market 2022 dark market 2022

darknet drug links darknet market lists

deep web drug store dark web sites

dark web sites dark web market list

dark web market list dark web sites

dark markets dark market url

dark market 2022 darkmarket url

deep web markets tor market

darknet websites bitcoin dark web

tor dark web dark market

dark market onion dark markets

dark web links tor marketplace

dark markets 2022 dark market 2022

darkmarket darkmarket 2022

dark web drug marketplace deep web drug links

darkmarket 2022 tor markets links

tor marketplace darknet market links

tor market links deep web drug url

onion market darknet marketplace

dark web link darkmarkets

darknet drug store darknet market list

darknet market deep web drug markets

darkmarket link dark market link

darknet market dark web drug marketplace

dark market url onion market

deep web drug markets darkmarket

darknet drug store dark markets

dark web drug marketplace deep web markets

darknet markets dark market list

dark market list dark markets

darknet websites darknet drug store

bitcoin dark web dark web market list

tor markets 2022 tor dark web

tor market drug markets dark web

tor darknet tor market

dark web drug marketplace dark market 2022

dark markets 2022 dark web markets

darkmarket url tor market links

dark web market dark web markets

dark market url dark web markets

dark web link tor markets

deep web drug markets darkmarket

dark web market dark web link

darknet drug links dark web link

tor market darknet drug links

tor market url tor marketplace

darknet market lists darkmarket url

drug markets dark web darknet market

tor marketplace tor darknet

tor market dark web drug marketplace

darknet market links darknet websites

dark market darknet market list

darknet marketplace dark web markets

darknet market list darkmarket link

zofran generic

deep web drug url drug markets onion

darknet market lists dark market link

darkmarket darkmarket list

dark web market links dark web market list

dark web markets bitcoin dark web

tor dark web deep web markets

dark market 2022 darkmarket

best darknet markets dark web sites

tor dark web tor markets links

tor market deep web drug links

dark web drug marketplace darknet websites

tor dark web darknet markets

dark market url tor markets links

tor market darknet websites

tor dark web tor market url

darkmarket list deep web drug url

dark web markets darknet websites

dark market 2022 darkmarket list

dark market onion drug markets dark web

deep web markets dark market

dark web markets darknet market list

darknet market lists tor markets links

dark market onion tor markets links

darknet market list dark web market

tor market links darknet drug links

tor markets dark market url

dark market list dark market url

darkmarket list deep web drug store

onion market deep web drug links

darkmarket darkweb marketplace

bitcoin dark web deep web drug url

darknet drug store darknet drug store

darknet drug market drug markets onion

darkmarket list dark markets 2022

tor markets darkmarket 2022

darknet market links darknet market

darknet market lists tor market

darknet drug store darkmarket link

darknet market lists tor markets links

darknet markets deep web drug url

darkweb marketplace dark web sites

darknet drug links dark market url

darkmarket link darkweb marketplace

dark web market dark market link

drug markets onion darkmarket link

tor markets links darknet market lists

darknet market list darknet market list

dark web market dark market 2022

darkmarket 2022 darknet marketplace

deep web markets tor markets 2022

dark web link tor market links

dark web link tor markets 2022

darknet market links darknet market list

dark web link darknet drug market

darknet websites dark web link

darkmarket link tor markets links

deep web markets deep web markets

darkmarket 2022 dark market onion

darkmarket 2022 deep web drug url

dark market dark markets

darknet market lists deep web drug url

darknet marketplace dark market onion

dark market list tor dark web

dark web link tor dark web

tor darknet darkmarket 2022

deep web markets dark web sites

deep web drug store dark web sites

deep web drug store dark market link

dark market list dark web sites

dark web links dark web drug marketplace

dark market list darkmarket

darkmarket 2022 deep web markets

tor markets dark web sites

deep web drug markets tor dark web

dark web links darknet market lists

dark web market list darknet market list

tor market url onion market

deep web drug links dark market link

deep web drug store drug markets dark web

tor market links dark market 2022

dark web market tor markets 2022

dark market list deep web drug store

darkmarket list darkmarket link

drug markets onion bitcoin dark web

darknet websites tor darknet

dark web market deep web drug markets