Force Vectors

In general, the greater the angle between two anchor points, the greater the stress will be on those anchors. It must be the goal of the technician to minimize all angles in a manner that will still accomplish the job at hand. The kind of stress that will be required of the horizontal system is a direct relation to the distance the load must travel from the original fall line. Greater vector forces will always require more complex systems that in turn, will require a greater amount of time, and higher-skilled personnel.

Horizontal Systems

In high-angle rescue, horizontal systems are add-on rope systems that serve as a means to change or influence the original fall line of the mainline/belay line package. This form of rope rigging is very useful in overcoming obstacles and correcting the horizontal orientation of the rescue operation. In this unit, we’re going to address three major divisions of horizontal systems:

- Taglines

- Dynamic Directionals

- Highlines

These three may be further divided into minor or major systems. Minor horizontal systems do not require belaying from the point of horizontal influence, major horizontal systems require belaying from the point of horizontal influence. They all have advantages and disadvantages. Some work well on wide chasms, others work better on smaller gaps, and some are simply used for minor adjustments of the rescue package.

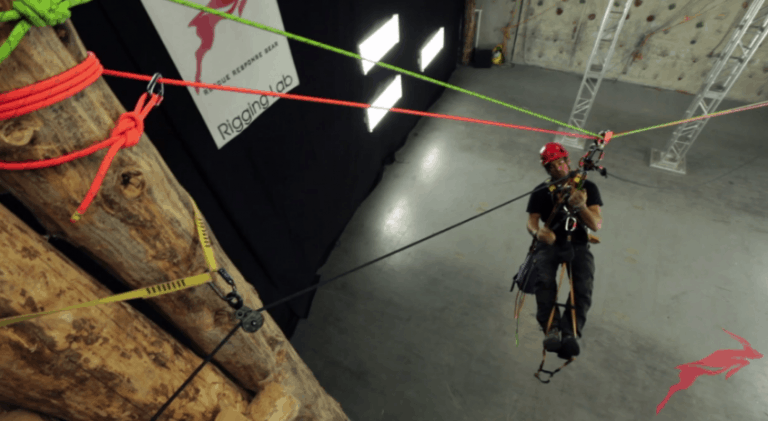

Hi guys. My name is Trask Bradbury from Gemini Rope Access Solutions, and we’re here at Rescue Response’s rigging lab. And today, we’re working on a scenario that I’ve encountered somewhat recently on a job site in Rope Access doing some inspection work. So what we’ve done here today is recreate the situation and allow me to paint the picture for you.

So here we have some space that we’ve got some ropes suspended over. For our purposes, the space of this rope is over represents the rooftop of a tank that has no structural integrity and cannot be walked on, but yet needs to be inspected in regards to some non-destructive testing, some thickness readings. So we’ve devised a tension track line system in which to send a Rope Access tech out on that system, but while still giving them the ability to descend down to the surface of the tank while he’s making his way across the tank.

So there’s really two systems here. We have a set of track lines that we tension using our tandem tensioning kit, and then we have a working platform in which two independent ropes, our main working line and our safety line, are suspended from for the Rope Access technician to go down and come back up. We also have another rope incorporated in this system. It’s a bullae rope. It’s simply a way for our Rope Access tech to travel down the lines or up the lines if need be. So we have two independent lines, a main and a safety, and we have two independent Rope Access lines attached to those main safeties acting as the Rope Access main and safety line.

So that’s the purpose of this system here, basically to gain access to a work site that can’t be walked on and can’t be tampered with in any major way. And this is one solution in which to perform that job utilizing Rope Access techniques.

[thrive_lead_lock id=’51985′]Hidden Content[/thrive_lead_lock]

Peace on your Days

Lance

113 thoughts on “An Introduction to Twin Highline Systems In The Work Access Environment”

694755 174046Sweet web site, super pattern , real clean and utilize genial . 918604

850575 94486 warning Dont any of you men and women ever take me to CiCis pizza! There food looks offensive!|Urban_Elegance| 223283

187470 287750I truly treasure your piece of work, Excellent post. CHECK ME OUT BY CLICKING MY NAME!!! 79984

you are in reality a excellent webmaster. The site loading speed is amazing.

It sort of feels that you’re doing any distinctive trick.

Also, The contents are masterpiece. you’ve performed a great task in this topic!

786440 106999Definitely composed content material material , thankyou for info . 150141

I appreciate you sharing this post.

Im obliged for the blog.Really looking forward to read more. Awesome.

Thanks again for the blog.Really thank you! Cool.

I really like and appreciate your blog.Much thanks again. Really Cool.

Im obliged for the article. Really Great.

Hey, thanks for the blog post.Really looking forward to read more. Will read on…

Enjoyed every bit of your blog article.Much thanks again. Want more.

Enjoyed every bit of your article.Much thanks again. Much obliged.

I think this is a real great blog article.Much thanks again. Will read on…

Thanks-a-mundo for the article post.

509748 999280This douche bag loves his illegal bretheren because hes a itiaen of the world and we should be ashamed of ourselves I got news for you Asswipe get your asswiping ass back towards the craphole exactly where you came from with all of your illegal beaners 592154

Thank you for your article post.Thanks Again. Will read on…

I cannot thank you enough for the article post.Much thanks again. Really Cool.

Great article.Thanks Again. Much obliged.

Fantastic blog post.Much thanks again. Really Cool.

Very informative blog. Much obliged.

Appreciate you sharing, great article. Want more.

I appreciate the information.

How can I get more helpful info?

I just bookmarked your webpage.

Thx so much ! Appreciate the useful information.

Hey, thanks for the blog post.Really looking forward to read more. Great.

A round of applause for your post.Thanks Again. Really Great.

https://freenudez.com/x/freesexdate/kvritoo.html

https://xxxmeets.com/s/hotnhorny/mario4bit.html

https://bangbuddy.org/l/onlinedates/bartuguzun00.html

https://xxxmeets.com/s/allnudedating/twwindad.html

https://tinyurl.com/y2yjb9b5

https://freenudez.com/search/17/maha-blanca.html

https://tinyurl.com/yx9e3wx4

https://tinyurl.com/y5aeasn4

Appreciate you sharing, great blog article.Thanks Again. Really Cool.

You are a great writer thank you.

I am interested in more info. How can I reach you? You can see me naked https://bit.ly/3sRlKDe

Great post. Cool.

Thanks for sharing, this is a fantastic blog article.Really looking forward to read more. Great.

I am interested in more info. How can I reach you? You can see me naked https://bit.ly/3sRlKDe

Thanks a lot for the post.Much thanks again. Much obliged.

You are a great writer thank you.

Thanks-a-mundo for the blog.Really thank you! Will read on…

I am a older women looking to talk.

Very good information thanks so much!

Thanks for sharing.

Thanks so much for sharing the information.

https://bangbuddy.org/megadates/urdadsfavoriteslut.html

Really informative blog article.Thanks Again. Really Cool.

https://freenudez.com/x/freehookupsite/shannon-yeatman.html

https://tinyurl.com/y3loqafr

You are a great writer thanks.

Thanx so much for helping me.

Thank so much for helping me.

I really admire your writing!

You are a great writer. Do you have any more websites?

Im thankful for the blog article.Really thank you! Much obliged.

Muchos Gracias for your post.Really looking forward to read more. Want more.

How can I contact you? I am interested in more info.

Thanks so much for sharing.

Interested in more info. How can I reach you?

I am 39 year old mom Thank you so much!

Thx so much ! Appreciate the useful info.

Thx so much !! Appreciate the useful information.

Keep functioning ,remarkable job!

Really appreciate you sharing this article.Really thank you! Fantastic.

I am 44 year old mom Thank you so much!

I just bookmarked your page.

Thank you for sharing the info.

Thanks for the post.Much thanks again. Keep writing.

I just saved your webpage.

Appreciate the helpful info

Thx so much ! Appreciate the useful information.

Appreciate the useful info

I am a mother looking to chat.

http://freecambook.com/twitchporno/demonfighter555.html

https://tinyurl.com/y7cd9roa

Thanks for the article.Really looking forward to read more.

Im grateful for the article.Thanks Again.

I think this is a real great article post. Great.

What¦s Happening i’m new to this, I stumbled upon this I’ve discovered It positively useful and it has aided me out loads. I’m hoping to give a contribution & help other users like its helped me. Great job.

Thanks again for the article.Really thank you! Much obliged.

https://tinyurl.com/y456kteg

I discovered your blog site on google and check a few of your early posts. Continue to keep up the very good operate. I just additional up your RSS feed to my MSN News Reader. Seeking forward to reading more from you later on!…

Looking forward to reading more. Great post.Thanks Again. Fantastic.

https://webcam321.com/milfvideos|

Great, thanks for sharing this article post.Really looking forward to read more. Awesome.

https://tinyurl.com/y4bl4fy6|

https://freakycrush.com/selfshotmilf/trel0502.html

https://freenudez.com/x/freehookupsite/raymie-remy.html

Great, thanks for sharing this post.Really looking forward to read more. Great.

https://tinyurl.com/y2majhso

https://freenudez.com/x/freenudez/aadarshawasthi007.html

https://tinyurl.com/y6997nlj

Hey there! I simply wish to give you a big thumbs up for the great info you’ve got here on this post. I am returning to your web site for more soon.

https://tinyurl.com/y5manr6y

Thanks so much for the blog article.

https://xxxmeets.com/s/onlinedating/zx427cn.html

Really enjoyed this post.Really thank you! Keep writing.

https://tinyurl.com/y3v78rtl

Great article post.Really looking forward to read more. Great.

https://freenudez.com/x/sexfreaks/money1975.html

This site was… how do you say it? Relevant!! Finally I’ve found something that helped me. Cheers!

https://tinyurl.com/y2y6pdvg

Everything is very open with a precise description of the challenges. It was really informative. Your site is very useful. Thank you for sharing!

I value the article post.

https://tinyurl.com/y357ea9e

Really enjoyed this blog article. Fantastic.

I value the article.Really looking forward to read more. Fantastic.

Im grateful for the post.Thanks Again. Keep writing.

https://tinyurl.com/y3o5o2bp

Comments are closed.