Welcome to the cutting-edge of rope rigging technology! In this post, we’re diving into the groundbreaking SQUID system, a game-changer for anyone involved in twin tension rope systems (TTRS). Whether you’re a seasoned professional or new to the field, understanding the innovative features and benefits of SQUID will redefine your approach to rigging, offering unparalleled safety and efficiency.

SQUID revolutionizes the setup of twin tension rope systems (TTRS), offering a streamlined and efficient approach. Its unique design features a central anchoring point for redundancy and two lateral points at right angles, ensuring optimal alignment of devices and balanced load distribution. This layout simplifies the process of pairing two mechanical devices for simultaneous operation, and is particularly conducive to the dual-handle shark fin (DOUBLE CLUTCH) technique, allowing a single user to manage twin tension effectively. SQUID’s design enhances the stability of both raising and lowering operations, reducing the risk of system failure and potentially decreasing the need for additional personnel.

This device makes the assembly of load-sharing systems more straightforward, offering versatile attachment points compatible with various connectors. These points are strategically positioned to facilitate smooth transitions when adding or removing hardware. SQUID’s orientation towards the load and its capacity to let components move freely play a critical role in preventing binding and mitigating the effects of a single anchor or line failure. Its robust, yet lightweight structure makes it an ideal tool for quickly setting up TTRS, bridal harnesses, cross hauls, and other systems.

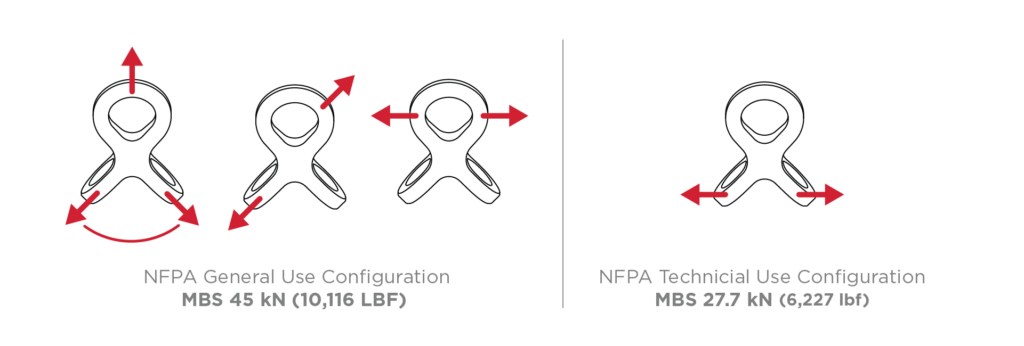

SQUID is CE marked and meets NFPA General Use standards in certain configurations, including TTRS. It also complies with NFPA Technical Use standards when its secondary points are utilized separately. SQUID optimizes device alignment in TTRS by enabling two devices to work in a mirrored, dual-handle manner. This configuration not only reduces the likelihood of single line failures but also limits the shock and extension in such events by distributing the load to an already tensioned rope. Utilizing SQUID in the DOUBLE CLUTCH Technique aligns with best practices for lowering and hauling systems, minimizing failure risks and potentially reducing the need for personnel.

As a rig plate, SQUID is essential for constructing anchors, managing rope systems, and organizing connections. It aids in creating a more efficient setup by spacing components appropriately and improving their visibility and accessibility. Its multi-planar secondary attachment points are specifically designed to align multiple devices and lines in an orderly manner, enhancing control and organization. SQUID’s ability to connect to various anchor points while reducing the potential for rotation and system extension during anchor movement or failure is a testament to its strength and compact design. Its inherent load-sharing capabilities, coupled with its natural orientation towards the load, significantly reduce the likelihood of binding and load shifting during dynamic or directional impacts.

In summary, the SQUID system is not just another rigging tool; it’s a leap forward in the world of rope systems. By combining ease of use, enhanced safety, and versatile functionality, SQUID stands out as a crucial asset for various operations. Whether it’s for rescue missions, industrial applications, or complex rigging tasks, SQUID brings a new level of confidence and capability to your toolkit. Embrace the future of rigging with SQUID, where safety meets innovation.

Features:

- Multi-planar rigging plate with perpendicular attachment points

- Optimizes device alignment for twin tension rope systems (TTRS)

- Enables single operator control for better shared tension

- Promotes smooth loading / unloading of connected hardware

- Allows components to move freely and orient toward the load

- Reduces shifting / extension in the event of line or anchor failure

- Aligns secondary points for high strength and easy load sharing

- Supports a variety of connection methods for versatile rigging

- Provides large collection points for building redundant systems

- Primary attachment point fits two (G) or three (T) carabiners

- Secondary attachment points fit one (G) or two (T) carabiners

- Simple and solid aircraft grade aluminum with no moving parts

- Strong, compact, and lightweight for multiple applications

Certifications:

- NFPA

- GENERAL USE (G) MBS 45 KN (10,116 LBF) – SPECIFIC CONFIGURATIONS*

- TECHNICAL USE (T) MBS 27.7 KN (6,227 LBF)

- CE

- PPE-R/RFU 11.114 VERSION 01

*Refer to the following diagrams for MBS. See User Manual for details.

Peace on your Days

Lance