Continued From A Rescue Rope and Cord Overview

There are a variety of rope constructions available on the market today, each designed for specific tasks and with different levels of safety incorporated. Common rope constructions include braided rope, twisted rope, and rope made from synthetic fibers. Braided rope is strong and durable, making it ideal for tasks that require a lot of wear and tear. Twisted rope is more flexible and can be used for tasks that require agility. Rope made from synthetic fibers is often used in applications where rope needs to be resistant to chemicals or extreme temperatures.

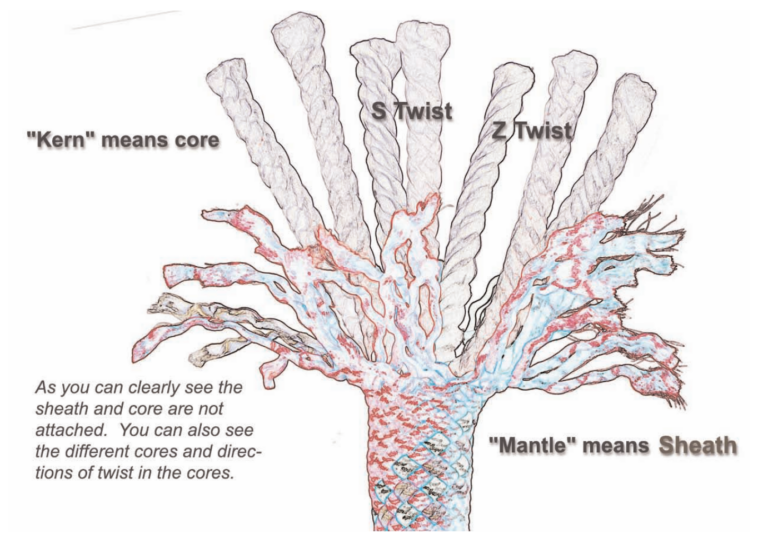

Kernmantle rope is the most common type of rope used in rescue operations. It is made of a core (kern) and a sheath (mantle), which provides a combination of high abrasion resistance and ease of handling. The core is made of parallel bundles of fibers, while the sheath protects the core from wear and tear. manufacturers often braided or twist the bundles in the core to give the desired elongation under load. Low stretch ropes for rescue or rappelling typically have little twist.

One of the most important parts of a kernmantle rope is the core. The core fibers are twisted or braided to provide the rope with energy absorption capability. The percentage of the load carried by the core of a kernmantle rope varies from 70% to 90% depending on the brand of the rope and its diameter.

Rope Fibers Comparison Chart

| Fiber Type | Strength | Stretch | UV Resistance | Gravity | Melting Pt. | Cost |

| Nylon | high | high | good | 1.14 | 210-254°C | moderate |

| Polyester | high | low | good | 1.38 | 256°C | moderate |

| Polypropylene | low | low | poor | .91 | 170°C | very low |

| Polyethylene | low | low | poor | .93 | 135°C | very low |

| Aramids | very high | very low | fair | 1.44 | 500°C (decompose) | very high |

| HMPE | very high | very low | fair | .96 | 135°C | very high |

| LCAP | very high | very low | fair | 1.41 | 330°X | very high |

Rope construction is a complex process that takes into account many factors, including elongation, impact absorption, handling, strength, and durability. There is no one definitive metric by which rope performance can be measured; instead, ropes must be tested in the field to prove their worth. There are several key phases of rope construction:

- First, the rope core is created. This is the central part of the rope that provides most of its strength.

- Next, the rope sheath is added. The sheath protects the core from abrasion and other damage.

- Finally, the rope ends are finished off and secured. This prevents the rope from unraveling and ensures that it can be properly attached to anchor points.

The process of rope construction involves twisting the fibers together to create the strands that make up the core and sheath. Twisting the fiber in the core adds mechanical elongation and determines the strength of the rope. The twist in the sheath yarns aids abrasion resistance, uniformity, and enhances the rope’s handling performance.

The rope is typically right-laid, meaning that the final twist is to the right. The handedness of the twist refers to the direction of the twists as they progress away from an observer. Z-twist rope is said to be right-handed, and S-twist rope is left-handed.

The rope is constructed by first spinning the individual fibres into yarns. These yarns are then twisted together to form strands, which are in turn twisted together to form the rope itself. The twist of the yarn is opposite to that of the strand, and that in turn is opposite to that of the rope. It is this counter-twist, introduced with each successive operation, which holds the rope together as a stable, unified object.

S and Z patterns S and Z patterns |

1928 braiding of rope 1928 braiding of rope |

Modern braiders Modern braiders |

Kernmantle rope is made with a core of long twisted fibers, surrounded by a braided outer sheath or mantle. The core provides most of the rope’s strength (about 70%), while the mantle protects the core and determines the rope’s handling properties (how easy it is to hold, to tie knots in, etc.).

In dynamic climbing rope, the core fibers are usually twisted to make the rope more elastic. Static kernmantle rope is made with untwisted core fibers and a tighter braid, which makes it stiffer and limits its stretch.

The rope used in rock climbing is referred to as “dynamic” rope. This type of rope is elastic and stretches under load, which helps to absorb the energy generated when arresting a fall. This prevents the forces from being too high and injuring the climber.

Conversely, “static” ropes have minimal stretch and are not meant for free falls. They are used in caving, rappelling, rescue applications, and industries such as window washing.

Dynamic kernmantle rope with twisted core Dynamic kernmantle rope with twisted core |

Section through kernmantle rope Section through kernmantle rope |

Braid on braid rope construction, also called double braid, involves braiding one rope inside of another. This is a common type of rope used on yachts. Double braid ropes can have as low as 50% of the load carried by the core, with the rest being carried by the sheath. This type of rope is seldom used in rescue systems, but is often used for specialty rope, such as rescue throw lines and ladder halyards.

There are many other types of braids and construction, however most it not all fall outside of the scope of this course.