In the realm of engineering and mechanical systems, the concept of Mechanical Advantage (MA) serves as a cornerstone in the design and operation of various systems, particularly in the context of raising and lifting heavy loads.

Welcome to ‘Raising Systems & Mechanical Advantage (MA), a journey into the world of mechanical advantage and its practical applications. In this project, we will delve into the intricate workings of pulleys, explore the distinctions between simple, compound, and complex mechanical advantage systems, and equip ourselves with the skills to construct progressive MA systems such as 3:1, 5:1, and 9:1 progressions, along with the innovative piggy-back systems. With a comprehensive understanding of these concepts, we will also master the operation of raising systems, ensuring safety and efficiency in real-world scenarios. So, fasten your seatbelts, as we embark on a learning adventure that will empower you with the knowledge and skills to conquer challenges that require lifting and raising with precision and mechanical advantage.

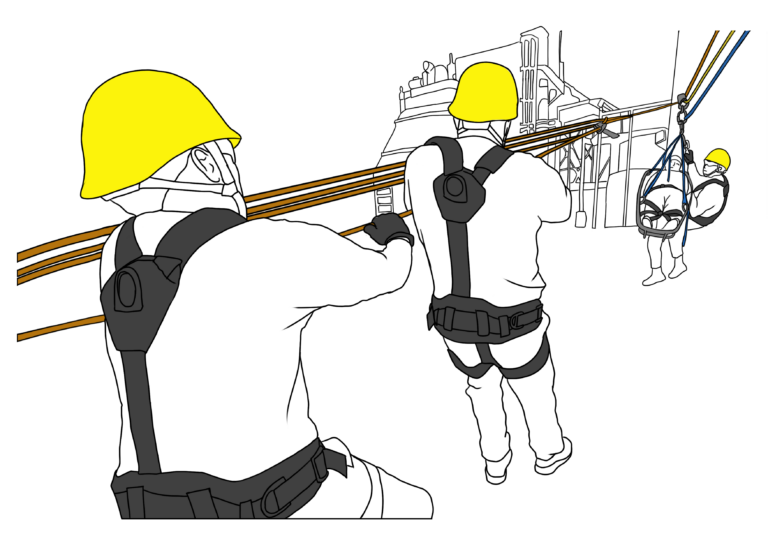

Rope rescue is a unique capability that enables the safe movement of patients in challenging vertical environments. Whether it’s a towering skyscraper, a remote wilderness area, or a confined space, rope rescue teams are equipped with the expertise and tools needed to navigate these complex terrains. This intricate process often involves the use of lever systems to create mechanical advantage, allowing rescuers to overcome gravity’s formidable force and transport patients safely from one location to another. In this exploration, we will unravel the fascinating world of rope rescue, shedding light on the techniques, equipment, and principles that make it all possible. Join us as we embark on a journey that combines innovation, skill, and precision to deliver critical care in the vertical realm.

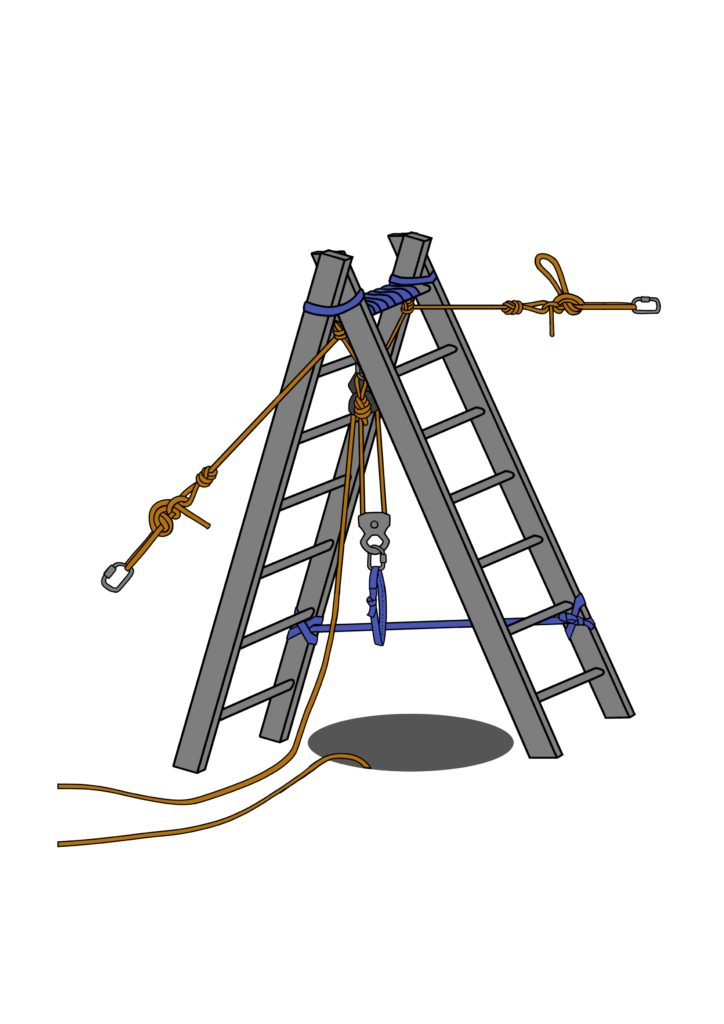

A raising system can be as simple as a few well-placed pulleys. Fixed pulleys form the core of such systems, offering a basic yet effective way to change the direction of the pull. This aspect becomes crucial when deciding whether the haul team should pull towards or away from the patient or package.

In addition to fixed pulleys, integrating change of direction pulleys is essential. These specialized pulleys ensure that the rope moves smoothly when the haul team operates in different directions, enhancing overall efficiency.

Furthermore, it’s important to consider the use of moving or mechanical advantage pulleys. These pulleys are designed to increase the mechanical advantage, making it easier for the haul team to lift or lower the load. Properly incorporating these elements into your raising system can significantly improve its performance and versatility in various situations.

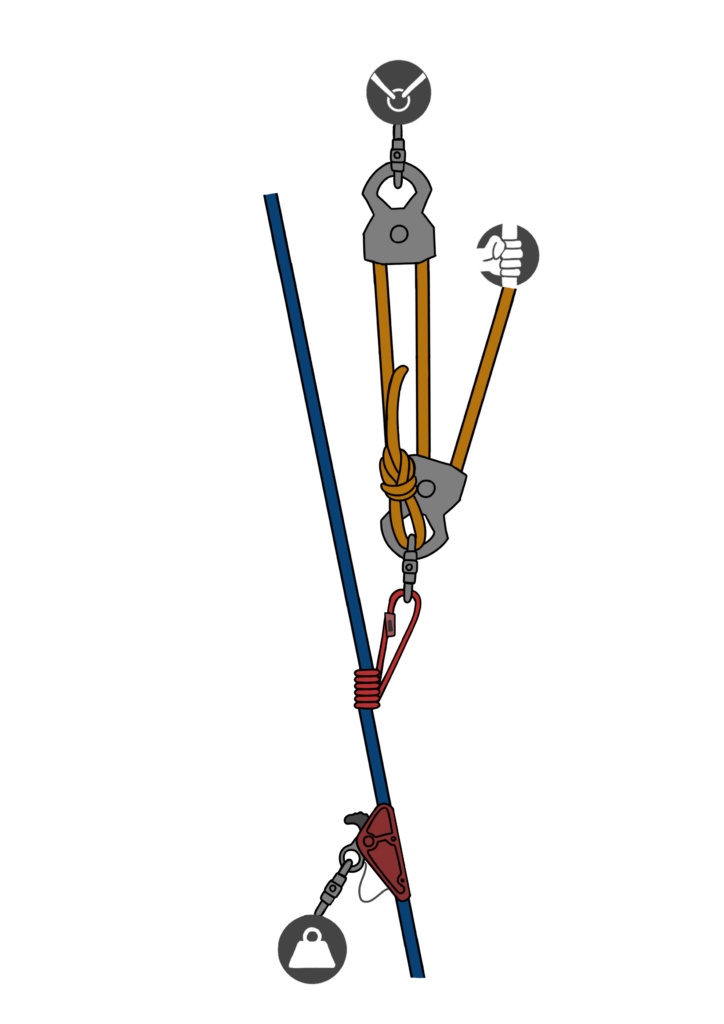

The ratchet, also known as a progress capture device or PCD, is a rope attachment that’s like a dependable handhold. It connects to the anchor point and firmly grips the rope. This grip is essential because it prevents the rope from slipping or sliding when you’re working with it. Think of it as a safety net that ensures you don’t lose progress and keeps things steady during rescue operations, making it a crucial tool for safety and control in rope rescue situations.

By combining various configurations of MA pulleys, fixed pulleys, ropes, anchors, and ratchets, we can tailor a system to match the specific task at hand. In most cases, striving for the lowest necessary mechanical advantage offers the optimal solution.

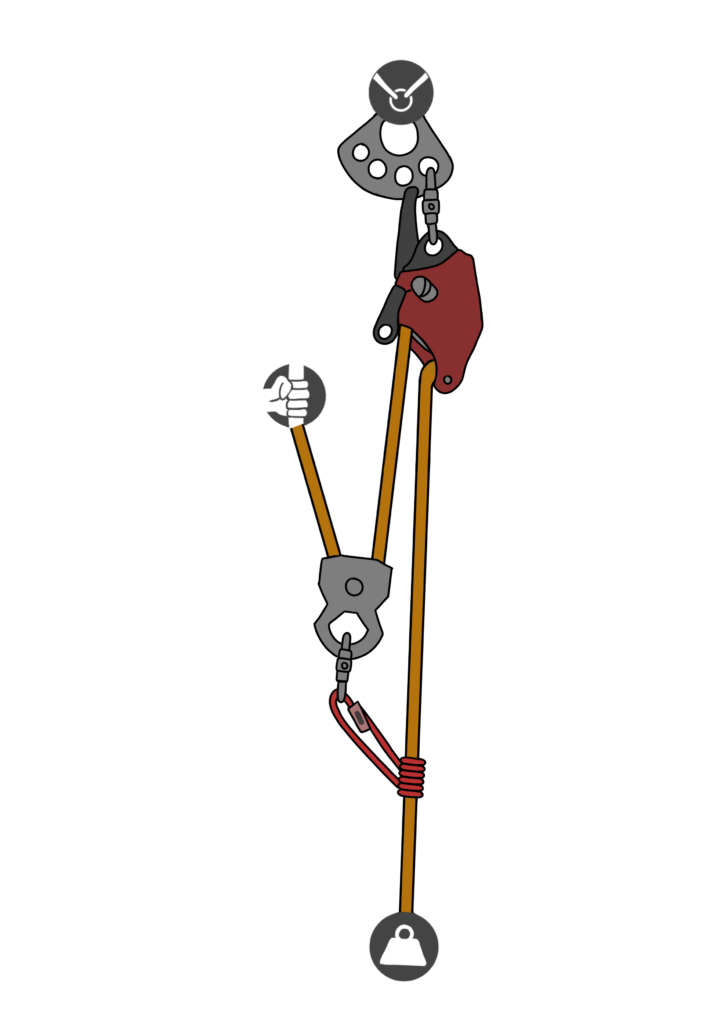

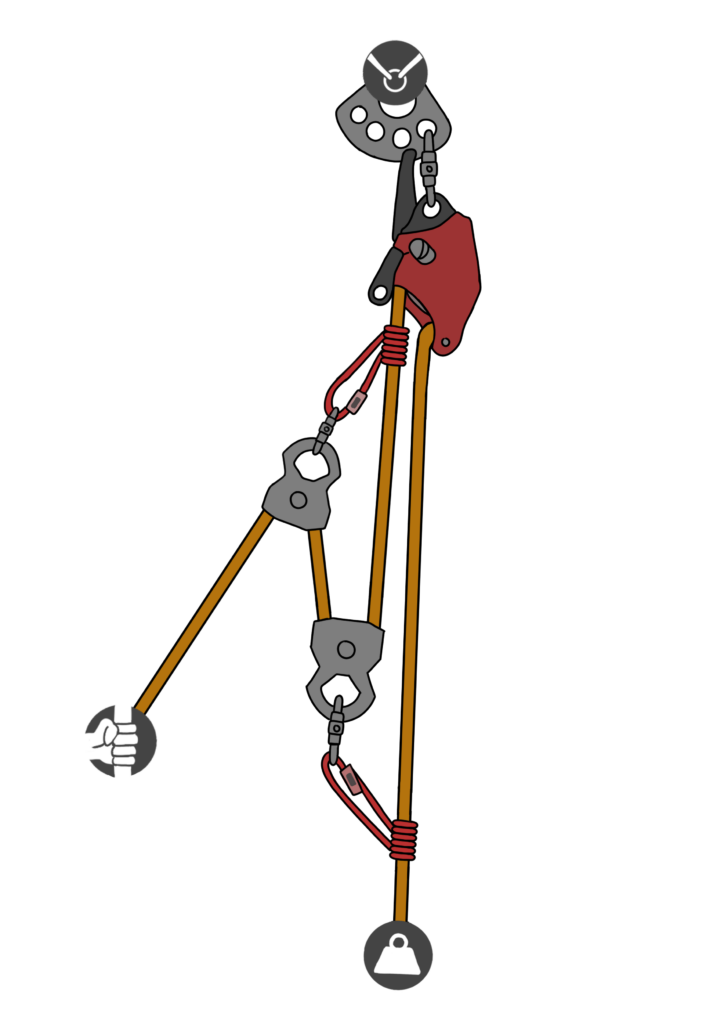

A simple mechanical advantage system, often referred to as a “Z system,” is a setup where all the components, including pulleys and ropes, move at the same speed or cover the same distance. This means that for every unit of effort applied, there’s an equal unit of movement in lifting a load. The Z system is a straightforward yet effective way to increase the mechanical advantage and reduce the physical effort required to hoist a load. It’s a commonly used configuration in various applications, particularly in situations where ease of use and simplicity are paramount.

In the world of mechanical advantage systems, two fundamental approaches emerge: the ‘simple mechanical advantage system’ and the ‘compound mechanical advantage system.’ These two configurations differ in their complexity and application. A ‘simple mechanical advantage system‘ is a straightforward setup where a single set of pulleys and ropes work together to provide a basic level of mechanical advantage. It’s often employed in scenarios where simplicity and ease of use are essential, such as in basic lifting tasks.

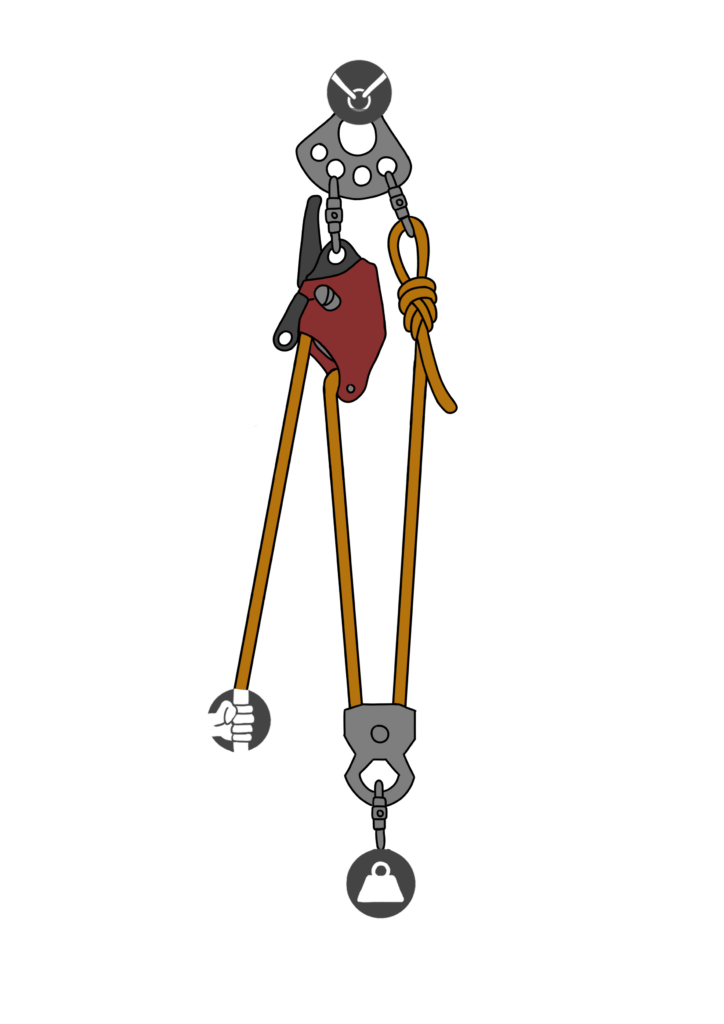

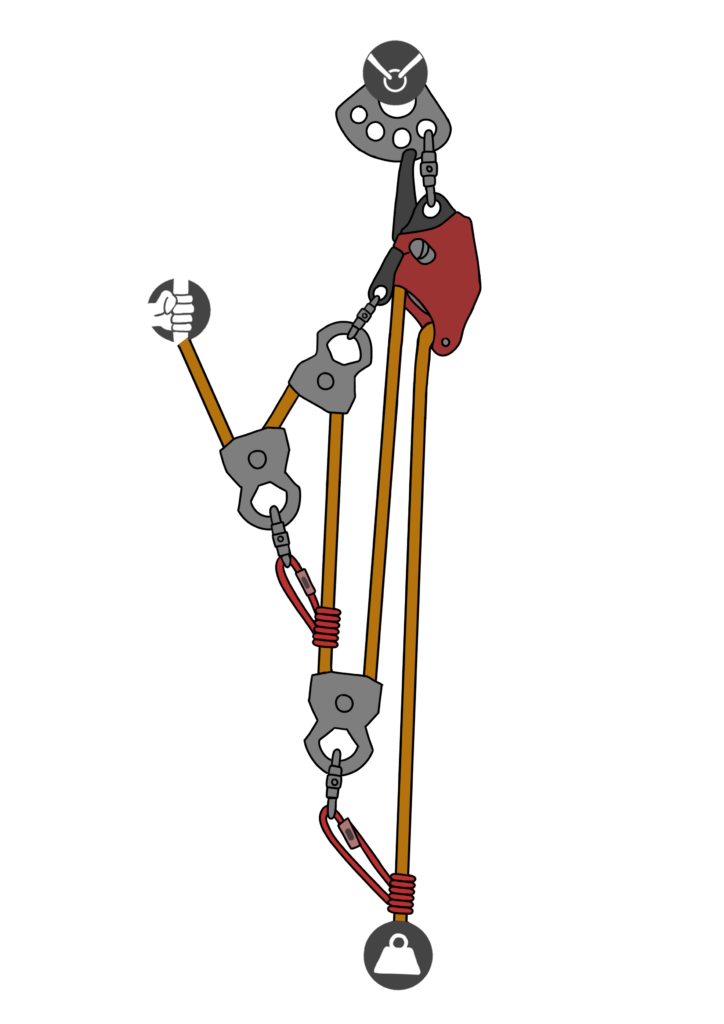

On the other hand, a ‘compound mechanical advantage system‘ is a more intricate arrangement that combines multiple sets of pulleys and ropes to achieve a higher level of mechanical advantage. This configuration is ideal for demanding tasks that involve lifting exceptionally heavy loads or situations where precision and control are critical.

In this exploration, we will delve into the distinctions between these two systems, understanding when and why each is chosen for specific applications, equipping you with the knowledge to harness the right mechanical advantage for your needs.

A “complex mechanical advantage system” is an advanced arrangement of pulleys, ropes, and other components that surpasses the complexity of both simple and compound mechanical advantage systems. In a complex mechanical advantage system, multiple sets of pulleys and ropes are intricately combined to provide an even higher level of mechanical advantage than a compound system. This configuration is typically reserved for exceptionally challenging lifting or hauling tasks where a substantial increase in mechanical advantage is required.

In some cases, a complex mechanical advantage system may be the most straightforward and efficient solution, especially when dealing with very heavy loads or when precision and control are vital. It’s important to select the appropriate level of mechanical advantage for the task at hand, and in some instances, using a complex system right away might be the simplest and most effective option.

Ultimately, the decision should be based on a careful assessment of the situation, taking into account factors like load weight, available equipment, safety considerations, and the expertise of the team. While complex systems may seem advanced, they can also simplify tasks by reducing the physical effort required and enhancing control, making them suitable for various scenarios beyond just special moments.

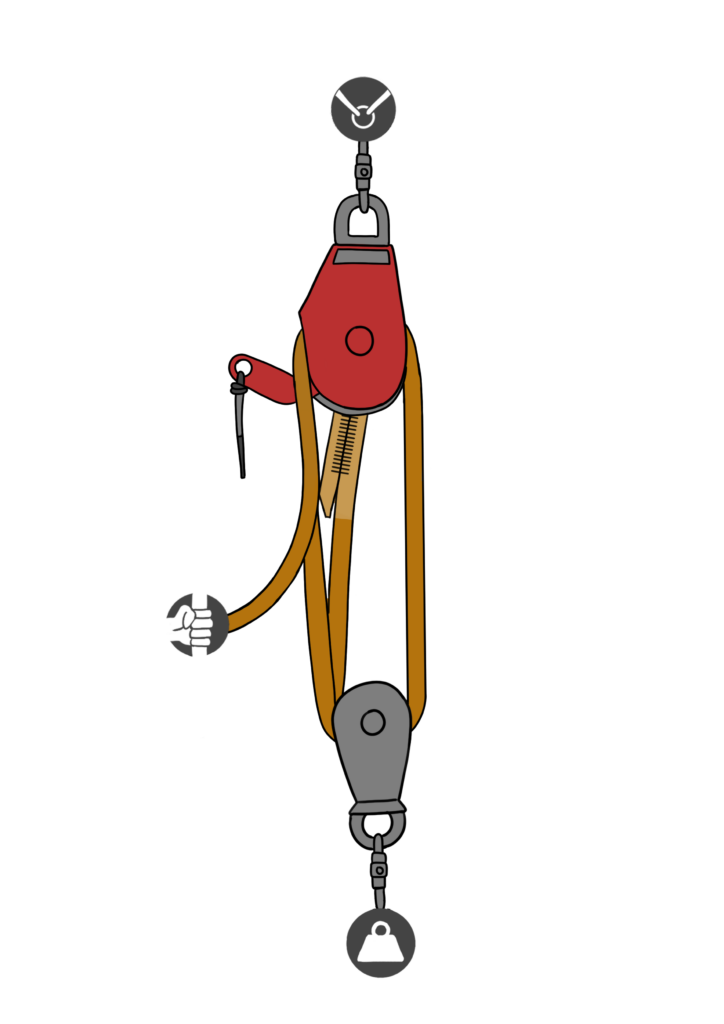

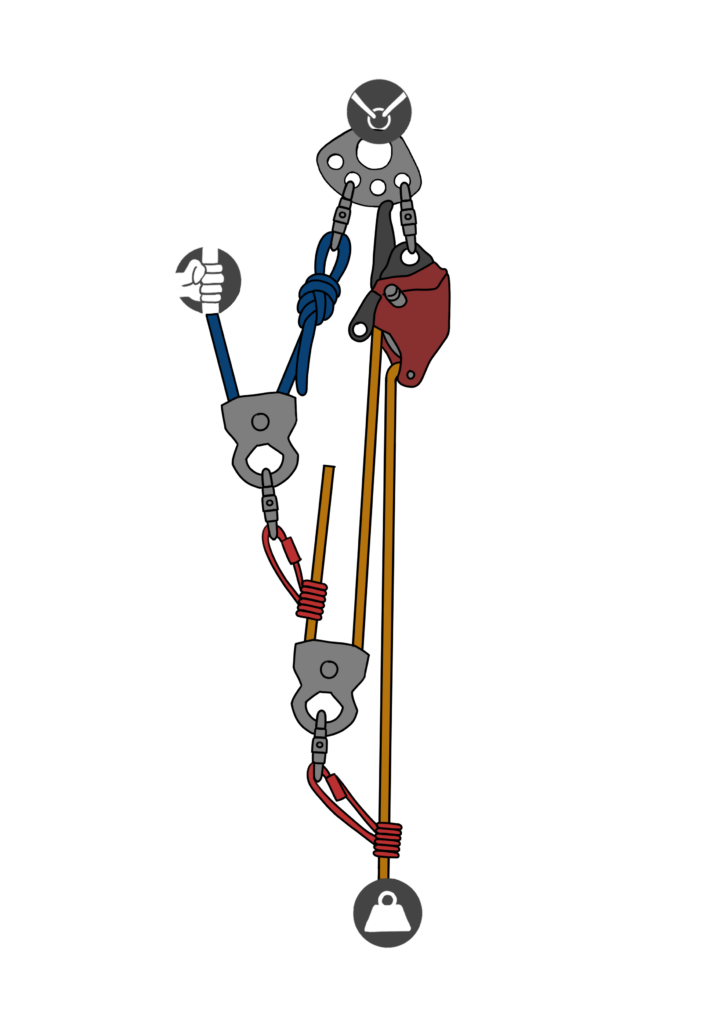

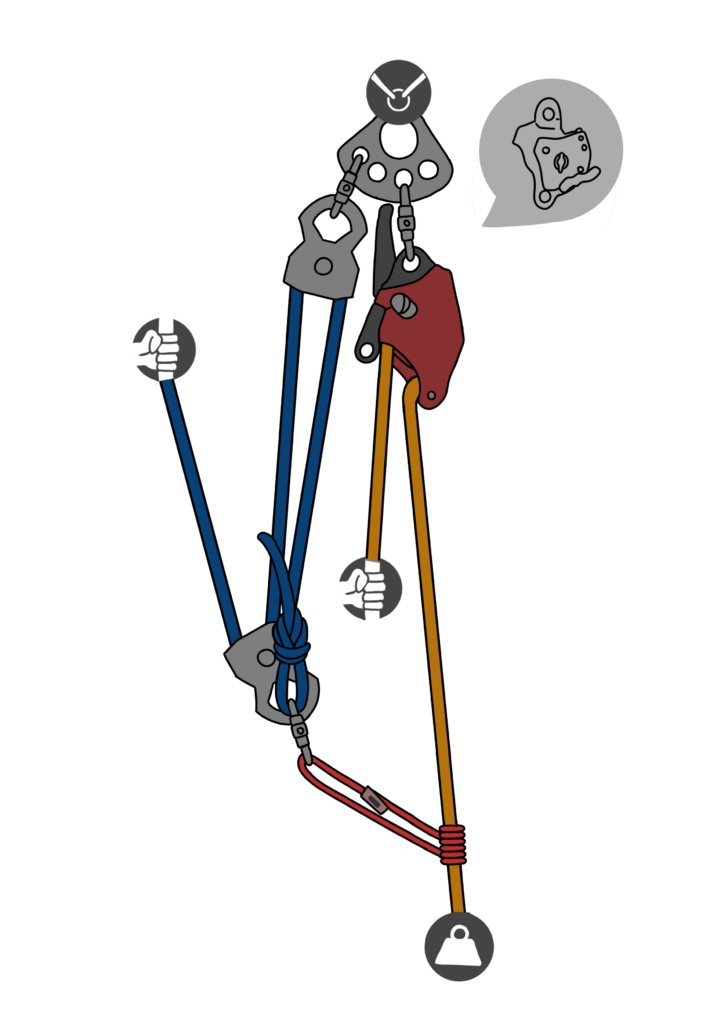

A “piggyback” pulley system is a mechanical advantage (MA) setup that involves the integration of two separate MA systems within a single rigging. In this configuration, one MA system is nested within another, essentially “piggybacking” on the primary system. Each system operates independently but contributes to the overall mechanical advantage.

Advantages of a Piggyback Pulley System:

- Increased Mechanical Advantage: By combining two MA systems, a piggyback setup can achieve a higher mechanical advantage, making it well-suited for lifting very heavy loads with less effort.

- Versatility: Piggyback systems offer versatility in handling a wide range of loads. Rescuers or riggers can adapt the configuration to suit the specific task by adjusting the number of pulleys and ropes in each system.

- Enhanced Control: The dual-system design allows for better control over the load, making it easier to maintain stability and prevent sudden movements during lifting or lowering operations.

Disadvantages of a Piggyback Pulley System:

- Complexity: Piggyback systems are more complex to set up and operate compared to single MA systems. This complexity can increase the risk of errors, particularly for inexperienced users.

- Increased Friction: With multiple pulleys and ropes, piggyback systems can introduce more friction into the system, potentially reducing efficiency and requiring more force to operate.

- Space and Weight: The additional hardware and rigging components in a piggyback system can take up more space and add weight to the overall setup, which may not be ideal in certain situations.

In summary, a piggyback pulley system offers the advantage of increased mechanical advantage and versatility for lifting heavy loads while providing better control. However, it comes with the drawback of added complexity, potential friction, and increased equipment weight and space requirements. The choice to use a piggyback system should be based on the specific needs of the task and the level of expertise of the team.

Peace on your Days

Lance