Choosing a Carabiner: Insights for Rigging and Rescue

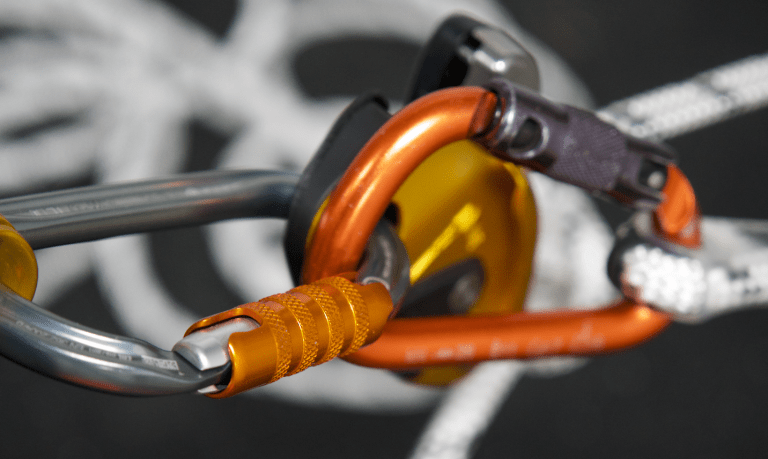

Carabiners are a cornerstone of rigging and rescue operations. Their role in ensuring safety, efficiency, and reliability cannot be overstated. However, the process of choosing the right carabiner can feel daunting due to the wide variety of options available. In this guide, we provide clear insights to help you select the most suitable carabiner for your needs.

Key Considerations for Carabiner Selection

When choosing a carabiner, you need to evaluate its shape, locking mechanism, and material based on your intended application. Below are the primary factors to consider:

1. Carabiner Shape

The shape of a carabiner directly impacts its strength, capacity, and functionality. Common shapes include:

- D-Shape: Ideal for maximum strength and secure load alignment. Excellent for hauling and anchor systems.

- Oval: Offers balanced loading but may lack the strength of other shapes. Suitable for use with pulleys or as general connectors.

- Pear Shape: Provides a large gate opening, making it ideal for multiple rope connections or for belaying.

2. Locking Mechanism

The locking system is crucial for maintaining safety and preventing accidental gate opening. Options include:

- Screw Lock: Simple and versatile but requires manual locking.

- Auto Lock: Offers quick and secure locking, ideal for high-frequency use.

- Triple Lock: Provides maximum security, especially for high-risk operations.

3. Material

- Aluminum: Lightweight and corrosion-resistant, best for general rescue and rigging.

- Steel: Heavy-duty and highly durable, suited for industrial applications or high-load systems.

Specialized Features to Consider

- Gate Opening Size: Ensure the gate opening is adequate for the ropes, pulleys, or hardware you intend to use.

- Strength Rating: Check the major axis, minor axis, and open gate strength ratings to ensure the carabiner meets your operational requirements.

- Certification Standards: Look for certifications such as ANSI, EN, or UIAA for quality assurance.

Avoiding Common Mistakes

- Overloading: Always distribute the load along the carabiner’s major axis. Avoid cantilever loading or side-loading.

- Improper Use: Regularly inspect for wear and ensure the locking sleeve is fully engaged before each use.

- Incompatible Connections: Use carabiners with compatible shapes and locking mechanisms to prevent system inefficiencies.

Recommended Applications

- Rescue Operations: Opt for pear-shaped or D-shaped carabiners with auto-locking mechanisms for secure and quick connections.

- Rope Access: Use steel carabiners for heavy-duty tasks, especially in industrial or high-load environments.

- Recreational Rigging: Lightweight aluminum carabiners are perfect for climbing or general rigging.

Explore Rigging Lab Academy Resources

At Rigging Lab Academy, we offer in-depth training and resources to enhance your knowledge of rigging systems. Explore our library of tools, techniques, and courses to refine your skills and improve safety in your operations.

Visit our comprehensive guide on carabiners to gain deeper insights and recommendations: Carabiner Guide

Conclusion

Choosing the right carabiner is not just about picking a piece of gear; it’s about ensuring safety and efficiency in your rigging and rescue operations. By understanding the nuances of carabiner shapes, locking systems, and material strengths, you can make informed decisions that enhance both performance and safety.

Peace on your Days,

Lance

31 thoughts on “Choosing A Carabiner”

439007 506949Wow! Thank you! I always wanted to write on my website something like that. Can I incorporate a portion of your post to my site? 30212

637957 238628You completed various great points there. I did a search on the theme and found the majority of folks will consent with your blog. 490479

Im obliged for the article. Really Great.

Thank you ever so for you article post. Awesome.

Hey, thanks for the article.Much thanks again. Great.

purchase ivermectin 3mg Cialis Viagra Barcelona

Very good article post.Really looking forward to read more. Will read on…

Thanks for sharing, this is a fantastic blog. Really Cool.

I really liked your blog article.Really looking forward to read more. Will read on…

I value the blog post. Great.

Thanks again for the post.Really thank you! Keep writing.

Thanks-a-mundo for the article.Really thank you! Really Cool.

Looking forward to reading more. Great blog article.Thanks Again. Really Great.

Generic Topiramate Online 200 who owns stromectol

Great blog article.Really looking forward to read more.

Very neat article post.Really thank you! Fantastic.

Thanks so much for the post. Fantastic.

I am so grateful for your blog article.Really looking forward to read more. Really Cool.

Im thankful for the article.Thanks Again. Really Great.

Thanks again for the article.Much thanks again. Keep writing.

Muchos Gracias for your blog article.Thanks Again. Want more.

448328 15369It can be tough to write about this subject. I feel you did an exceptional job though! Thanks for this! 153379

Thanks so much for the blog article. Fantastic.

wow, awesome blog post.Thanks Again. Really Cool.

A round of applause for your blog.Much thanks again.

Very neat blog post.Much thanks again. Much obliged.

This is one awesome article.Much thanks again. Really Great.

Say, you got a nice blog post. Much obliged.

Thank very much for helping me.

For severe headaches, contact your healthcare provider buy cialis online forum

How can I reach you? I am interested in more info.

Comments are closed.