A rope rescue system is a critical piece of equipment for those in the emergency services industry. It consists of multiple components that link together to allow personnel to safely move an injured person or other load from a hazardous location quickly and efficiently. Ensuring safe operations requires conducting a rigorous system analysis so you can identify the weakest areas in the chain and take corrective action if needed. This analysis is especially important when members of the public are depending on your system for their safety and well-being. It’s vital to know where the weakest point in a system is, so you can be sure it won’t fail in any situation.

Catastrophic failures can be devastating. When a component fails and the load is released, it can cause enormous damage to the system as a whole, much less ‘the human effect”.

When a component fails and the load is not released, the system may stop working, which can have terrible consequences for the patient if it takes a long time to fix the issue.

Analyzing a rope rescue system is essential to ensure safety. We must look at the entire system, not just the individual parts, and each component has a “minimum breaking strength” or MBS that has been determined by a specific test method. However, these methods may not always accurately reflect the way it is being used in the system.

Rope Rescue System Analysis

The analysis of a rope rescue system has three parts: critical point analysis, whiteboard analysis and the whistle test. Critical point analysis involves assessing the potential risks or points of failure within the system. Whiteboard analysis is a step-by-step review of the entire system, providing an opportunity to visualize any possible problems before actually operating in real-world conditions. The whistle test is a way to assess the performance of the system under simulated or actual operational conditions, allowing for troubleshooting and adjustments before implementation. By analyzing all aspects of the rope rescue system before implementing it, potential risks can be reduced and overall safety increased.

Critical Point Analysis

Critical point analysis is a method of assessing the safety of a system by looking into each individual component. It determines if any certain part failing would cause catastrophic failure to the whole system. If a critical point is identified, it needs to be addressed and resolved with either a redundant component or some other form of backup. Additionally, if there’s an additional system meant to act as a backup for the main one, like a belay system, it should be taken into account when assessing safety. It’s essential to consider each element of a system and its potential failures in order to ensure that catastrophic failure can be avoided. Critical point analysis is an effective way to do this.

Whistle Test

The whistle test is an important part of any system setup. It’s a theoretical test that determines the safety measures in place if all the operators let go at once. A “swarm of hornets or bolt of lightning” could distract both the haul team and belayer, causing them to release their lines unexpectedly. The tandem prusik is an example of a system that should pass the test, however a munter belay would not. Even though these tests are theoretical, they should still be taken seriously as they could potentially save lives. Ensure you are familiar with the systems being used and that your team is prepared for any eventuality.

Whiteboard Analysis

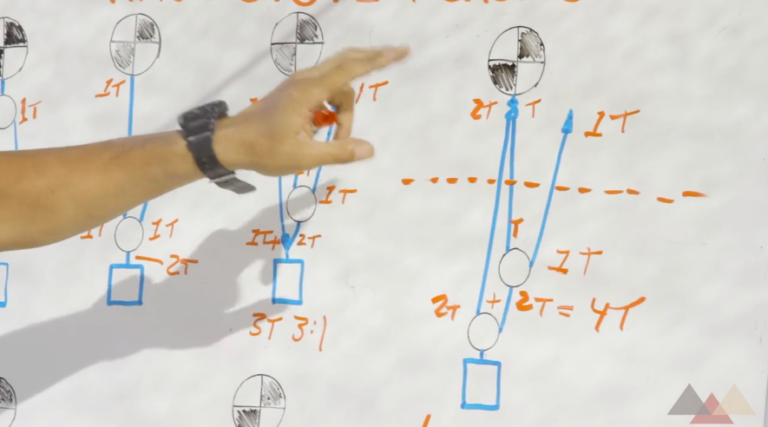

The whiteboard analysis is a crucial step in evaluating the safety and strength of a rescue system. It requires identifying all components of the system, assessing their relative strength, and determining how they are used. The way each link is rigged and its individual strength will determine the overall system strength, which is represented by the System Safety Factor (SSF). Both static and dynamic loads must be evaluated in a whiteboard analysis to ensure that the system can withstand anticipated forces. The information gathered will help determine if the system is suitable for its purpose or whether changes need to be made for improved safety. It’s critical to understanding how each piece of equipment works together as part of an overall rescue system.

Whiteboard analysis is an essential tool for understanding and solving mechanical systems. It involves drawing out the system on a whiteboard or other large surface, including angles, change of directions (pulleys or gears) and any factors that could affect the forces on the system. To get started, let’s look at a simple static system as an example. We can use this system to walk through the process of whiteboard analysis and understand how various elements affect each other, in order to determine an overall solution. By studying the position, direction, and magnitude of different forces and components within a system, it’s possible to get a better grasp on what is causing problems or inefficiencies.

Example 1 of a Simple System 1:1

|

Example 2 of a Simple System 1:1

|

When it comes to whiteboard analysis, the anchor point is one of those factors that can be hard to anticipate ahead of time. Depending on the rescue task at hand, the anchor point may vary from location to location. Knowing this information beforehand will help inform your decision-making and allow you to make more accurate predictions about possible outcomes for each situation you encounter. Tie-off points are an example of fixed points that can be incorporated into a whiteboard analysis. In this context, a tie-off point is an anchor that is part of the landscape or structure and remains in place for repeated use. For instance, on a rescue truck, the same point may be used over and over to secure the vehicle during operations.

The below begs the questions now… what is your SOP for SSF (SSSF)?

| Example 1 10.5:1 | Example 2 15:1 |

|

|

Having the information of what could be the weakest link in a system before going out on a rescue mission is invaluable. Knowing exactly what type of knot to use, and how tight it should be, can help ensure that nothing goes wrong during the mission. By using an SOP requiring a doubled loop when tying anchor with one inch webbing, and making sure that the interior angle of the loop is no more than 90 degrees, rescuers can be confident that their anchor point will be strong and secure. This analysis helps keep everyone safe in the field and is an important part of any mission.

Despite replacing the 30 kN T-use carabiners with g-use 40 kN carabiners to match the NFPA rope being used, the safety factor (SSF) revealed that the weakest link in the system was still the knotted rope. This meant that while adjusting SSF did increase safety levels, it didn’t address the weak link in the system. Therefore, more needs to be done to ensure safety for any rigging system.

In the diagrams below we have actual systems that would be deployed in any given operation.

First Example SSSF of 7.5:1

|

Second Example SSSF of 10:1

|

We’ve adjusted the system as compared to the first couple of examples.

|

|

Peace on your Days

Lance