The T-method of analysis allows us to account for the friction in the pulleys and calculate a more accurate mechanical advantage. The efficiency of each pulley is calculated by measuring the difference between its theoretical output force, from our original system analysis, and its actual output force, determined experimentally. The efficiencies are then multiplied together to calculate the total efficiency of the system, and the actual mechanical advantage is found by dividing this total efficiency into the theoretical mechanical advantage. Knowing the actual mechanical advantage allows for more accurate calculations to be made when designing a hauling system. By accounting for friction in its analysis, the T-method provides a greater degree of precision when predicting how much output force will be produced by a given haul team. This can be an invaluable tool when dealing with complex hauling systems.

There are two main sources of friction in a pulley. The first is caused by the rotational force of the sheave on the axle, which can be greatly reduced by using sealed ball bearings or Oilite bushings. Sealed ball bearing pulleys use a special oil-impregnated alloy bushing to minimize rotational friction, but they are slightly less efficient than sealed ball bearing pulleys when new. As the bushing in a bushing pulley wears or accumulates dirt and grime, its efficiency will decline.

The degree of friction in a pulley system depends on the characteristics of the rope used and how it interacts with the sheave. Different ropes have different coefficients of friction, which will affect the efficiency of the pulley system. Tests have indicated that this difference can cause up to 15% reduction in efficiency, depending on the type of rope used.

The mechanical advantage of a pulley system is highly dependent on its overall efficiency. As the number of pulleys in the system increases, so does the cumulative effect of inefficiencies. In a single pulley system with one change of direction, losses can be as high as 5%. With four pulleys, such as that found in a 9:1 MA system, the losses can be as high as 20%. To maximize the efficiency of your pulley system, it is important to ensure that all components are of a high-quality and that they are properly maintained. Additionally, a well-designed pulley system should also have fewer changes in direction to minimize any potential losses. By taking these steps, you can ensure that your pulley system is as efficient as possible.

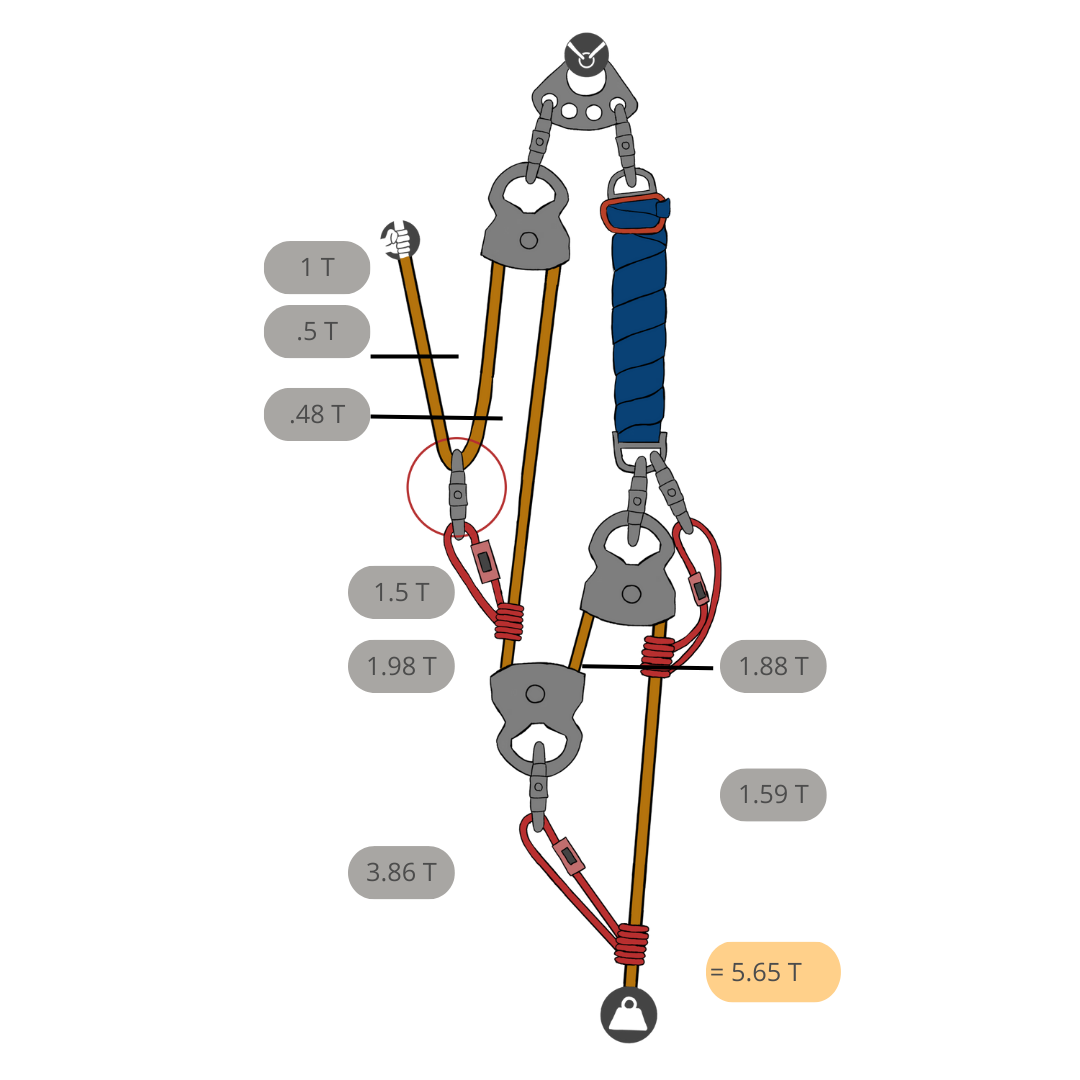

Determining Actual MA using T-Method

4 – .85 Efficient Pulleys 4 – .85 Efficient Pulleys |

4 – .95 Efficient Pulleys 4 – .95 Efficient Pulleys |

Best Place to Place Carabiners in a 9:1 MA as Determined Through T-Method

Carabiner-Pulley in the #2 Position |

Carabiner-Pulley in the #3 Position Carabiner-Pulley in the #3 Position |

Carabiner-Pulley in the #4 Position Carabiner-Pulley in the #4 Position |

Environmental Concerns

When performing a system analysis, it is important to consider the environmental factors that may cause force multiplying or strength reducing situations. These conditions occur when a rigging system is set up in an environment that has irregular features; for example, uneven surfaces, slopes, or obstructions can all affect the tension and load on components of the rig. Such environmental factors can be difficult to eliminate and must therefore be accounted for in the system analysis. Taking into account environmental conditions prior to setting up a rigging system will help ensure its safety and effective use. If such conditions are not taken into account, they can lead to increased strain on components of the system and put workers at risk of injury or death. As such, it is essential to factor in environmental conditions during system analysis for the safety of workers and the successful completion of a task.

Human Factors

Systems analysis must take into account the human element, which cannot be quantified in numerical terms or used as part of the system safety factor estimate. Despite this, human behaviour must still be considered when designing and evaluating systems. Human error is one of the leading causes of accidents and incidents within any given system, so identifying potential sources of errors and designing mitigation strategies is essential.

The human factor is a critical element of the rescue operation. The level of training and experience of the team plays a significant role in the ability to manage complex systems, while also adapting to changing conditions. It is important that all members are well-versed with system operations and maintain a high degree of competence when facing potentially unpredictable circumstances. Furthermore, the systems and personnel must be able to perform reliably in spite of distractions that may occur throughout the course of the mission. Proper planning and ample preparation are essential for a successful rescue operation.

Peace on your Days

Lance