There are four main types of pulleys that are commonly used in technical rope rescue:

- standard sheave pulleys

- swivel pulleys

- prusik minding pulleys

- knot passing pulleys

In addition to these pulleys, there exists a number of other more unique or niche type of multi purpose pulleys. We’ll discuss these in another lesson.

- Standard sheave pulleys are the most common, using side plates as they pulleys axle. This provides better strength to weight ratio and cleaner lines across the sheave itself.

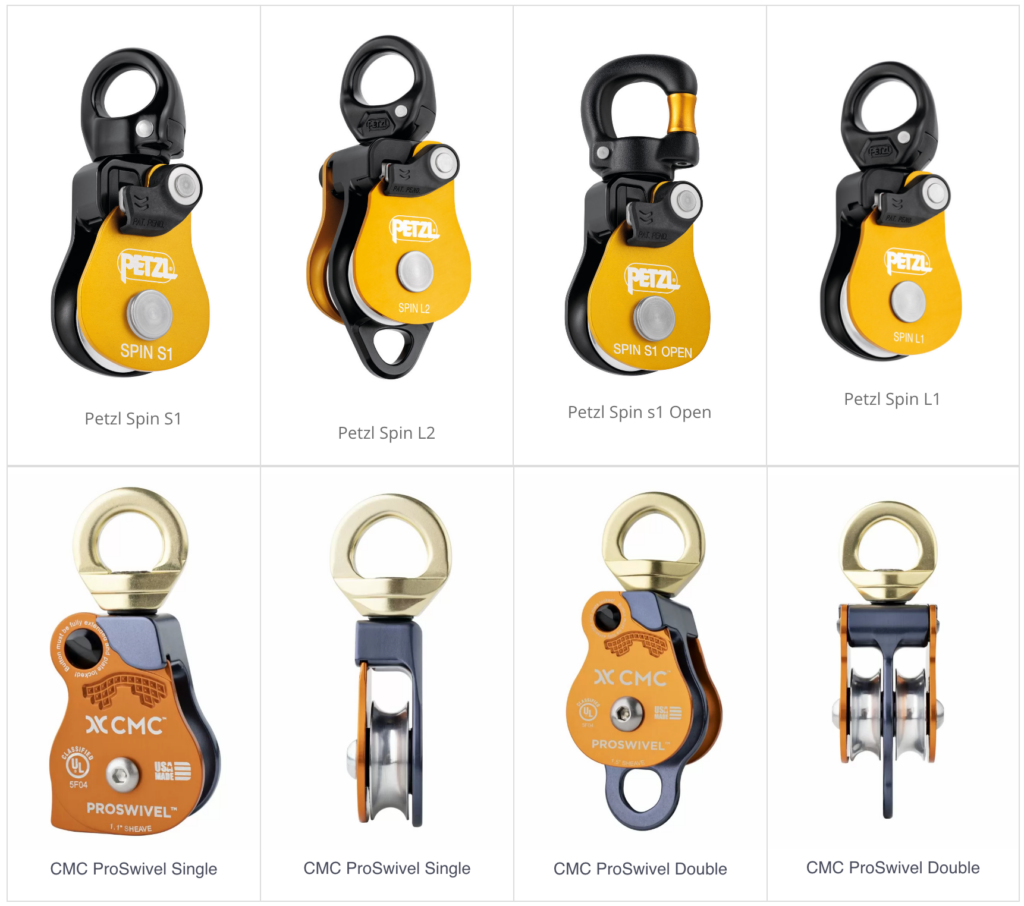

- Swivel pulleys are the most common type of pulley used in rope rescue. They are designed to allow the rope to rotate freely around the pulley, which prevents the rope from becoming twisted or tangled.

- Prusik minding pulleys are used to attach a pulley to a rope that is already in place. This type of pulley is used to create mechanical advantage systems, which can be used to increase the force that can be applied to a load.

- Knot passing pulleys are used to attach a pulley to a rope that is already in place. This type of pulley is used to create mechanical advantage systems, which can be used to increase the force that can be applied to a load. Knot passing pulleys are also used to allow knots to pass through the pulley without catching or jamming.

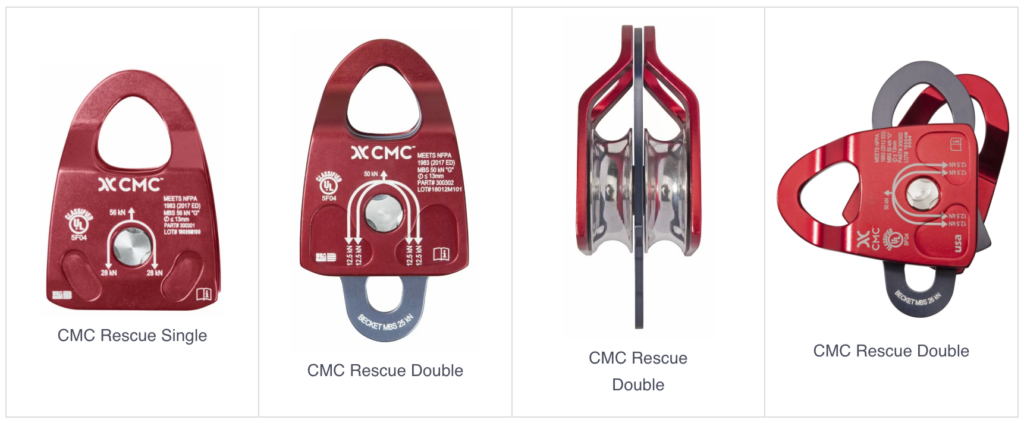

There are two main types of pulleys –

- double sheave pulleys

- single sheave pulleys

Double sheave pulleys have two wheels, while single sheave pulleys only have one.

Double sheave pulleys are typically used for larger mechanical advantage systems, as they provide more pulley power and allow for a greater range of motion. Single sheave pulleys are typically used for smaller mechanical advantage systems, as they are lighter and more compact.

Both double sheave pulleys and single sheave pulleys can be used for a variety of technical rope rescue applications, and the type of pulley you use will depend on the specific needs of your rescue system.

Standard Side Plate Style Pulleys

The most common type of pulley is the side plate pulley. Side plate pulleys are strong and durable, making them ideal for use in technical rope rescue operations. However, they can be also heavy and bulky, which can make them difficult to transport, so make sure you get the specific strength to weight needed.

Swivel Style Pulleys

A prusik minding pulley is a technical rope rescue pulley that helps to control the movement of a load. It is typically used in situations where there is a need to keep the load from moving too far or too fast.

The technical rope rescue community has long recognized the value of a good pulley. The prusik minding pulley is a particularly useful tool, as it helps keep the rope in line while also providing a swivel action. This is particularly useful when using a high directional. By having the pulley and swivel incorporated into the one unit, the working height that would be used by a separate swivel and carabiner is not lost.

Prusik Minding Pulley

Prusik minding pulleys (PMP) are specially designed pulleys that can be used to attach a prusik cord. This allows the pulley to be used as an anchor point, or for belaying and rappelling. Prusik minding pulleys are an essential piece of gear for technical rope rescue.

The PMP is a high-strength, lightweight pulley that is perfect for use in technical rope rescue applications. Made with machined aluminum side plates, the pulley is designed to be strong and durable, while also being lightweight. The sealed ball bearings provide high efficiency, and the stainless steel axle assembly reduces snagging on rocks, roots, and uneven surfaces. The pulley are either single or double sheave.

Prusik-minding pulley is ideal for mountain rescue, swiftwater, or other technical teams where equipment weight is a significant consideration. Breaking strengths of 22kN (4950 lbf) are strong enough to handle even the most challenging rescues.

So if you’re looking for a pulley that can handle the toughest rope rescue situations, the prusik-minding pulley is a great choice.

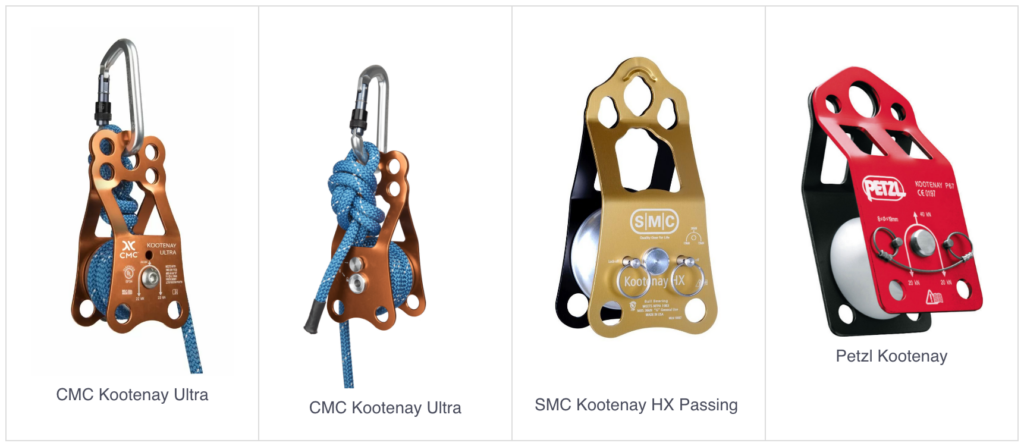

Knot Passing Pulleys

The kootenay pulley is an essential piece of gear for technical rope rescue and highlining. It is strong and versatile, allowing you to easily separate tag lines and hoist ropes. The rigging holes also allow for English and Norwegian reeves, which provide greater stability and reduce the risk of spinning the load.

For English and Norwegian reeves, a greater spread between the hoist pulleys significantly reduces the chance of inadvertent spinning of the load.

The large diameter sheave runs on sealed ball bearings, providing optimum efficiency and strength to weight ratio. The primary carabiner hole accepts numerous rescue carabiners. Secondary carabiner holes are provided for use with tax or belay lines. Two quick-release pins may be used to “lock off” the sheave when a high strength tie-off is required.

Strength and Ratings

Technical rope rescue equipment is designed to have a strength rating that greatly exceeds the minimum breaking strength of the ropes with which they will be used. This is due to the fact that technical rope rescue systems are often loaded in ways that put sudden and extreme stress on individual components. By having a high strength rating, technical rope rescue gear is able to withstand this stress and continue to function properly.

When looking at the strength rating of a technical rope rescue pulley, it is important to note that there are two different standards that pulleys can be rated against: NFPA 1983 and CE/EN 12492. NFPA 1983 is the standard used in the United States, while CE/EN 12492 is the standard used in Europe.

Pulleys that are rated according to NFPA 1983 will have a Minimum Breaking Strength (MBS) rating. This is the minimum amount of force that the pulley can withstand before breaking. For technical rope rescue pulleys, the MBS rating must be at least 22 kN (4950 lbf).

Pulleys that are rated according to CE/EN 12492 will have a Weighted Breaking Strength (WBS) rating. This is the average amount of force that the pulley can withstand before breaking. For technical rope rescue pulleys, the WBS rating must be at least 15 kN (3360 lbf).

It is important to note that the MBS and WBS ratings are not interchangeable. A pulley that has an MBS rating of 22 kN may not have a WBS rating of 15 kN. When choosing a technical rope rescue pulley, be sure to check that it is rated according to the standard that is required in your region.

NFPA 1983 states that all Technical Use pulleys must have an MBS of 22kN or higher. NFPA 1983 was written with the assumption that technical rescue teams are highly trained and skilled in the use of this specialized equipment. NFPA 1983 also requires that all components be proof-loaded to 125% of their rated strength before they leave the factory.

In addition to being built to higher strength standards, Technical Use pulleys are also designed with extra features that make them more user-friendly in technical rescue applications. For example, many Technical Use pulleys have an integrated cam locking device that can be used to lock off the rope and prevent the pulley from moving. This is a very important safety feature when you are using a pulley to raise or lower a technical rescue victim.

When choosing a pulley for your technical rescue operations, it is important to select one that meets the strength and durability requirements of NFPA 1983. You should also look for a pulley that has the extra features that will make your technical rescue operations safer and more efficient.

Peace on your Days

Lance