Advanced Rigging Techniques

Advanced Rigging Techniques are more than just ropes and anchors—it’s a blend of skill, precision, and adaptability. Advanced techniques allow teams to tackle complex scenarios with efficiency and confidence. Below, each heading dives deeper into the strategies and systems that elevate rigging from fundamental knowledge to professional expertise.

Two-Tension Rope Systems (TTRS): Redefining Redundancy

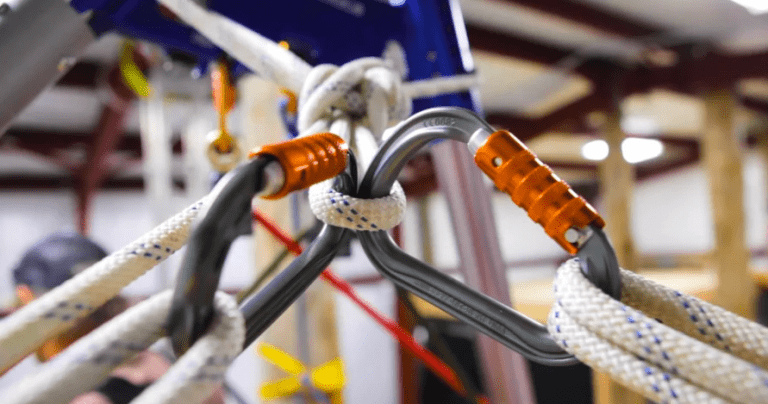

Traditional single-tension systems rely on a main line bearing the load, with a backup belay line that activates only if the main line fails. While effective in the past, this design comes with limitations, such as delayed redundancy and uneven load distribution. Two-Tension Rope Systems, or TTRS, address these challenges by having both ropes actively engaged in load management.

How TTRS Enhances Control

In TTRS, both ropes are tensioned equally, creating a balanced load system. This ensures smoother operations, minimizes rope stretch, and reduces wear on equipment. By actively engaging both ropes, TTRS delivers precision control that is invaluable in complex rescues.

Applications in Rescue and Rigging

- High-Angle Rescues: TTRS provides consistent tension during steep descents or ascents, ensuring the load remains stable even over challenging terrain.

- Confined Spaces: When space is limited, TTRS allows for controlled movement without the abrupt shifts common in single-tension systems.

- Urban Settings: Navigating sharp edges and architectural obstacles becomes more efficient with balanced rope tension.

The dynamic nature of TTRS makes it the gold standard for operations requiring smooth, predictable load transitions and active redundancy.

Mechanical Advantage Systems (MAS): Efficiency Meets Strength

Mechanical Advantage Systems amplify human effort, allowing riggers to lift or lower heavy loads efficiently. At their core, MAS use pulleys and rope systems to multiply input force, making even the heaviest loads manageable. Advanced MAS setups, such as compound systems, push the boundaries of what these configurations can achieve.

Advanced MAS Configurations

- Simple Systems: A basic 3:1 or 4:1 setup works well for moderate loads but can be stacked for greater efficiency.

- Compound Systems: Combining systems (e.g., a 3:1 into a 5:1) creates higher mechanical advantage while maintaining operational simplicity.

- High-Efficiency Pulleys: These components reduce friction, ensuring that input energy translates directly into lifting power.

Safety Enhancements

Integrating progress capture devices such as CMC MPDs or Prusiks adds a layer of safety by preventing the load from slipping or rolling back. These devices are essential in operations where pauses or adjustments are required.

Artificial High Directionals (AHDs): Elevating Rigging Operations

Artificial High Directionals are purpose-built structures that provide elevated anchor points for rigging systems. By raising ropes off the ground, AHDs reduce friction, protect edges, and allow for smoother transitions. Depending on the scenario, AHDs can be configured as monopods, bipods, or tripods.

Configurations and Their Strengths

- Monopods: Lightweight and compact, monopods are ideal for confined spaces. Their simplicity makes them quick to deploy, though stabilization with guy lines is crucial.

- Bipods: Providing a stable base, bipods are excellent for edge transitions where the load needs to remain steady.

- Tripods: The most versatile of AHDs, tripods can handle heavy loads and allow for multi-directional rigging, making them indispensable in demanding environments.

Applications

AHDs are especially valuable in:

- Edge Transitions: Keeping ropes elevated reduces drag and ensures load stability.

- Confined Spaces: When natural anchors are unavailable, AHDs provide a reliable solution.

- Industrial Operations: They offer a safe and efficient means of lifting or lowering equipment in construction or maintenance settings.

Edge Management Techniques: Control and Safety

Edge transitions are a critical aspect of rigging and rescue, often representing the most challenging point in a system. Proper edge management not only protects ropes and equipment but also ensures smooth load movement, preventing accidents and delays.

Tools for Effective Edge Management

- Edge Rollers: These tools guide ropes over sharp or uneven surfaces, reducing friction and prolonging rope life. Modular rollers can be adjusted to fit irregular terrain.

- Elevated Directionals: Using AHDs or other elevated anchors prevents the rope from dragging along the edge, minimizing wear and tear.

- Anchor Placement: Strategically placing anchors to create smoother rope angles reduces tension and ensures a more efficient system.

Considerations

Friction is a constant enemy in edge management. The combination of proper tools and strategic planning ensures that operations remain efficient while protecting both gear and personnel.

Real-World Problem Solving: Adapting to Challenges

Even the best-laid plans can encounter unforeseen obstacles in the field. Advanced rigging isn’t just about mastering systems—it’s about thinking critically, adapting to the environment, and making informed decisions under pressure.

Strategies for Problem Solving

- Scenario Analysis: Before acting, assess the entire situation, including environmental factors, potential hazards, and team resources.

- Flexible System Design: Be ready to modify or combine systems to address the unique demands of the operation.

- Team Coordination: Clear roles and communication are essential for avoiding confusion and ensuring smooth execution.

Examples

In a high-angle rescue with shifting weather, a team might need to switch from a bipod to a tripod AHD for added stability, while simultaneously adjusting the anchor layout to accommodate changing conditions. The ability to think on your feet and adapt systems is what separates competent riggers from experts.

Conclusion: Elevating Rigging Expertise

Advanced rigging techniques are the backbone of successful operations in challenging scenarios. From the balanced precision of Two-Tension Rope Systems to the adaptability of Artificial High Directionals and the efficiency of Mechanical Advantage Systems, each tool and technique plays a critical role in ensuring safety and effectiveness. By mastering these strategies and combining them with critical thinking, rigging professionals can confidently tackle any challenge.

- Edge Management Techniques in High-Angle Rescue

For a deeper dive into handling edge transitions and minimizing rope wear, visit Edge Management Techniques in High-Angle Rescue. - Go 0 to 60 in Your Understanding of Mechanical Advantage

Explore detailed insights into mechanical advantage systems and their applications at Go 0 to 60 in Your Understanding of Mechanical Advantage. - Collaborative Precision: Mastering High-Angle Rescues with Dual Rope Systems

Learn more about Two-Tension Rope Systems and their practical applications in Collaborative Precision: Mastering High-Angle Rescues with Dual Rope Systems.

Peace on your Days

Lance

6 thoughts on “Advanced Rigging Techniques”

445310 925841 There are some intriguing points in time in this post but I dont know if I see all of them center to heart. There is some validity but I will take hold opinion until I appear into it further. Excellent article , thanks and we want much more! Added to FeedBurner as effectively 330181

794399 520361Dead written articles , Actually enjoyed reading . 893949

578457 582058I like this web site because so significantly utile stuff on here : D. 321173

790662 744315I like this weblog really much, Its a rattling nice billet to read and discover info . 178554

Hi! This is my 1st comment here so I just wanted to give a quick shout out and tell you I truly enjoy reading through your articles. Can you recommend any other blogs/websites/forums that go over the same subjects? Thanks for your time!

of course like your website but you have to check the spelling on quite a few of your posts. A number of them are rife with spelling issues and I find it very troublesome to tell the truth nevertheless I’ll definitely come back again.

Comments are closed.