Types of Pulleys in Technical Rope Rescue

In technical rope rescue, various pulleys serve specific functions to ensure safety, efficiency, and precision. Here’s an overview of the primary types commonly used:

Main Types of Pulleys:

- Standard Sheave Pulleys

- These are the most commonly used pulleys, featuring side plates that function as the axle.

- Known for their excellent strength-to-weight ratio and smooth sheave operation, they are versatile for many general rigging applications.

- Swivel Pulleys

- Designed to prevent rope twisting or tangling by allowing the pulley to rotate freely.

- They are widely used in rope rescue for systems where movement and orientation of the load are critical.

- Prusik Minding Pulleys

- Specialized for mechanical advantage systems, these pulleys are designed to manage prusik hitches effectively, ensuring smooth operation without jamming.

- They provide a reliable way to create controlled hauling systems.

- Knot Passing Pulleys

- These pulleys allow knots to pass through without catching or jamming, making them ideal for complex systems that require uninterrupted rope movement.

- Often used in long line systems or highline rescues.

In addition to these, many niche and multi-purpose pulleys exist for specialized applications, which will be explored in other lessons.

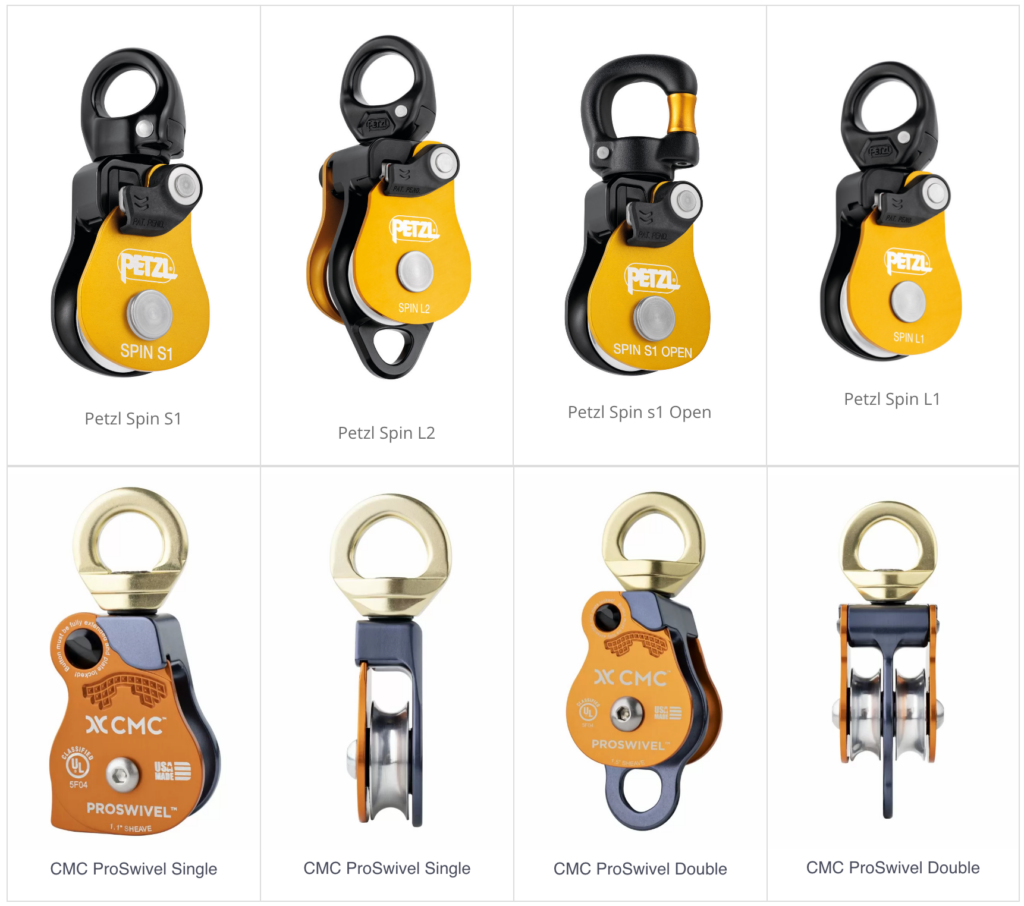

Single Sheave vs. Double Sheave Pulleys:

- Single Sheave Pulleys

- Lightweight and compact, they are ideal for smaller mechanical advantage systems or quick setups.

- Best suited for scenarios where portability is a priority.

- Double Sheave Pulleys

- Featuring two wheels, they provide greater pulley power and are excellent for larger mechanical advantage systems.

- Ideal for complex setups requiring additional range of motion and efficiency.

Both types are essential tools in a rescuer’s toolkit, with the choice depending on the system’s specific requirements.

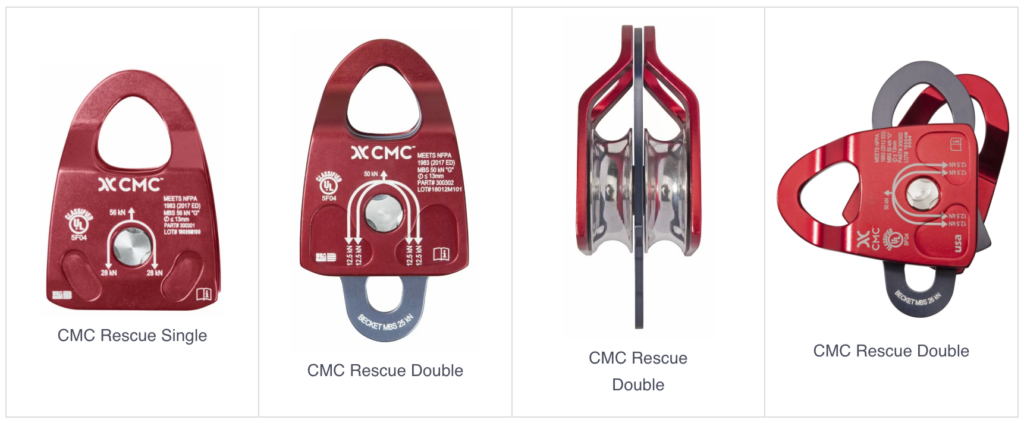

Standard Side Plate Style Pulleys:

Side plate pulleys are a staple in technical rope rescue due to their durability and strength. While their robust construction makes them reliable, they can be heavier and bulkier compared to other pulley types. It’s crucial to select a pulley with the appropriate strength-to-weight ratio for your needs to balance performance with portability.

Swivel Style Pulleys

Swivel-style pulleys are an essential tool in technical rope rescue, combining a prusik-minding function with a built-in swivel for enhanced control and efficiency. These pulleys are designed to manage the movement of a load, preventing it from moving too far or too fast, while also allowing for smooth rotation and alignment of the rope system.

The integrated swivel is particularly valuable when working with high directionals, as it helps keep the rope properly oriented, reducing twists and unnecessary friction. By combining the pulley and swivel into a single unit, swivel-style pulleys eliminate the need for a separate swivel and carabiner, preserving working height and streamlining the system setup.

Swivel-style pulleys offer a compact, efficient solution for situations requiring precise load control and are a go-to choice for technical rope rescue teams.

Prusik Minding Pulley

Prusik minding pulleys (PMPs) are specifically designed to work seamlessly with prusik cords, making them a versatile tool for anchor points, belaying, and rappelling. These pulleys are a critical component in technical rope rescue systems.

Constructed with machined aluminum side plates, PMPs offer a combination of high strength and lightweight design, ensuring durability without adding unnecessary weight to your gear. The sealed ball bearings deliver exceptional efficiency, while the stainless steel axle assembly minimizes snagging on rough or uneven terrain. PMPs are available in single or double sheave configurations, catering to various rescue needs.

With a breaking strength of 22kN (4950 lbf), these pulleys are built to withstand demanding rescues, making them suitable for mountain rescue, swiftwater operations, and other technical scenarios where weight and reliability are paramount.

For challenging rope rescue situations, the prusik-minding pulley is an indispensable choice, offering both strength and efficiency in one compact design.

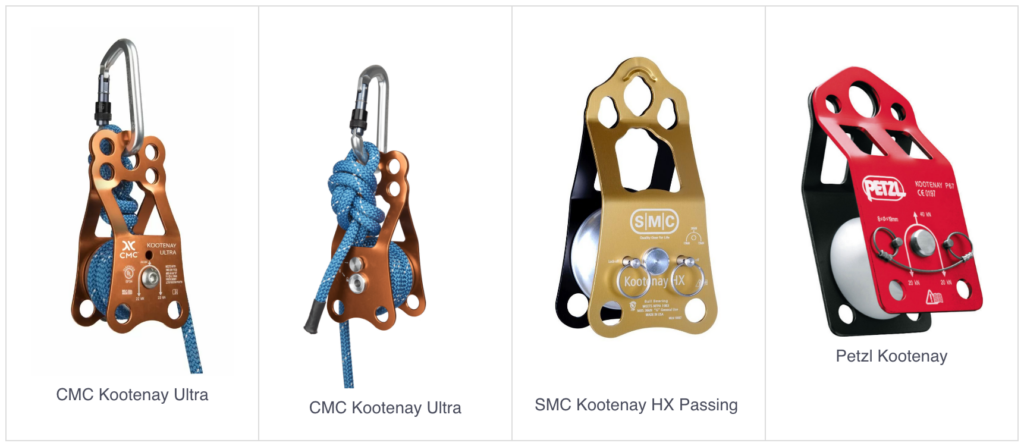

Knot Passing Pulleys

The Kootenay pulley is a vital tool for technical rope rescue and highlining, valued for its strength and adaptability. Its design enables efficient separation of tag lines and hoist ropes, while the rigging holes support English and Norwegian reeves. These configurations enhance stability and minimize the risk of load spinning during operations.

In particular, a wider spread between hoist pulleys in English and Norwegian reeves significantly reduces the potential for unintended load rotation, ensuring greater control and safety.

The Kootenay pulley features a large-diameter sheave mounted on sealed ball bearings, optimizing efficiency and providing an excellent strength-to-weight ratio. Its primary carabiner hole accommodates a wide range of rescue carabiners, while secondary carabiner holes allow for the integration of tag or belay lines. Additionally, two quick-release pins can be used to “lock off” the sheave, creating a high-strength tie-off point when needed.

Strength and Ratings in Technical Rope Rescue

Technical rope rescue equipment is designed to meet stringent strength standards to ensure safety and reliability under extreme conditions. The strength ratings of these components far exceed the minimum breaking strength (MBS) of the ropes they are paired with, allowing them to withstand sudden and extreme stress often encountered during rescue operations.

Standards for Pulley Strength Ratings

Technical rescue pulleys are rated according to two primary standards: NFPA 1983 and CE/EN 12492. Each standard outlines specific requirements to ensure the equipment performs safely under load.

- NFPA 1983 (United States Standard):

- Minimum Breaking Strength (MBS): This is the minimum force a pulley can withstand before failing.

- For technical rescue pulleys, the MBS must be at least 22 kN (4950 lbf).

- All components rated under NFPA 1983 are proof-loaded to 125% of their rated strength before leaving the factory.

- CE/EN 12492 (European Standard):

- Weighted Breaking Strength (WBS): This is the average force a pulley can withstand before failing.

- For technical rescue pulleys, the WBS must be at least 15 kN (3360 lbf).

Key Differences Between MBS and WBS Ratings

It is important to note that MBS and WBS ratings are not interchangeable. A pulley with an MBS rating of 22 kN may not have a WBS rating of 15 kN. When selecting a pulley, always ensure it meets the required standard for your operational region.

Features of Technical Use Pulleys

Pulleys designed for technical rescue not only meet higher strength standards but also include features that enhance their functionality and safety:

- Integrated Cam Locking Devices: Some pulleys include cam locks to secure the rope, preventing unintended movement during raising or lowering operations.

- User-Friendly Design: These pulleys are specifically designed for high-stress rescue scenarios, making them easier to handle and operate.

When choosing a pulley for technical rescue, prioritize models that meet NFPA 1983 standards for strength and durability. Opt for pulleys with added safety features to enhance operational efficiency and minimize risk.

Peace on your Days

Lance