Modernizing Rescue Operations

For over 30 years, I’ve seen countless advancements in the field of technical rescue. Yet, for every great innovation, there are lingering relics of outdated gear, techniques, and mindsets that hinder progress. It’s time for a reset—a deliberate effort to remove what no longer serves us and embrace what does. Consider the Figure 8 plates and rappel racks, for instance; these items are past their prime and should find their place in a museum, not in modern rescue operations.

Modern technical rescue success hinges on alignment and coordination among technical riggers, administration/purchasing teams, training teams, and gear providers. Below is an expanded 3-step framework to optimize operations while considering current industry searches and best practices.

Step 1: Establish Open Communication Channels

Why it Matters: Communication is the foundation for synergy between all stakeholders. Misalignment can result in inappropriate gear purchases, ineffective training, or operational inefficiencies.

Implementation:

- Regular Coordination Meetings:

- Schedule monthly or quarterly meetings to bring together riggers, purchasing teams, trainers, and gear providers.

- Use these sessions to discuss ongoing challenges, emerging needs, and industry trends.

- Share Insights:

- Encourage each group to highlight pain points, whether it’s outdated gear, procurement delays, or gaps in training.

- Use these insights to inform decision-making and prioritize actions.

- Define Common Goals:

- Establish clear objectives such as improving rescue times, reducing gear malfunctions, or enhancing team competency.

- Align all stakeholders on these goals for a unified approach.

Step 2: Collaborative Decision-Making Process

Why it Matters: Involving all parties in decisions ensures that the gear, training, and operational strategies meet real-world needs.

Implementation:

- Inclusive Decision-Making:

- Involve riggers, trainers, and gear providers in selecting new equipment and designing training programs.

- This ensures decisions are grounded in practical use and technical expertise.

- Technical Requirements:

- Leverage riggers’ expertise to assess the technical demands of operations. Ensure purchasing teams are equipped with this knowledge when evaluating products.

- Training Needs Assessment:

- Trainers identify essential skills for upcoming rescue challenges and ensure training programs align with operational demands and the gear being deployed.

- Vendor Collaboration:

- Gear providers should present recommendations on equipment, detailing how it aligns with operational needs.

- Providers can also guide teams on maintenance protocols to maximize the gear’s lifespan.

Step 3: Continuous Improvement and Feedback Loop

Why it Matters: A proactive feedback loop enables adaptation and ensures ongoing alignment with evolving rescue demands.

Implementation:

- Feedback Mechanisms:

- Collect feedback on gear performance, training efficacy, and procedural efficiency after every significant operation.

- Use surveys, debrief sessions, and equipment inspection logs for comprehensive insights.

- Adaptation and Innovation:

- Continuously refine training programs, replace outdated gear, and optimize operational workflows based on feedback.

- Stay updated on industry standards and adopt relevant innovations.

- Collaborative Problem-Solving:

- When issues arise, hold cross-functional sessions to brainstorm solutions. Combining the expertise of diverse stakeholders often leads to innovative approaches.

Training and Gear Provider Involvement

Why it Matters: Gear service providers are invaluable partners in ensuring the effective use and maintenance of equipment.

Educational Support:

- Providers can offer guides and resources detailing technical specs, best practices, and troubleshooting tips.

- Trainers can use these materials to create more accurate and practical training sessions.

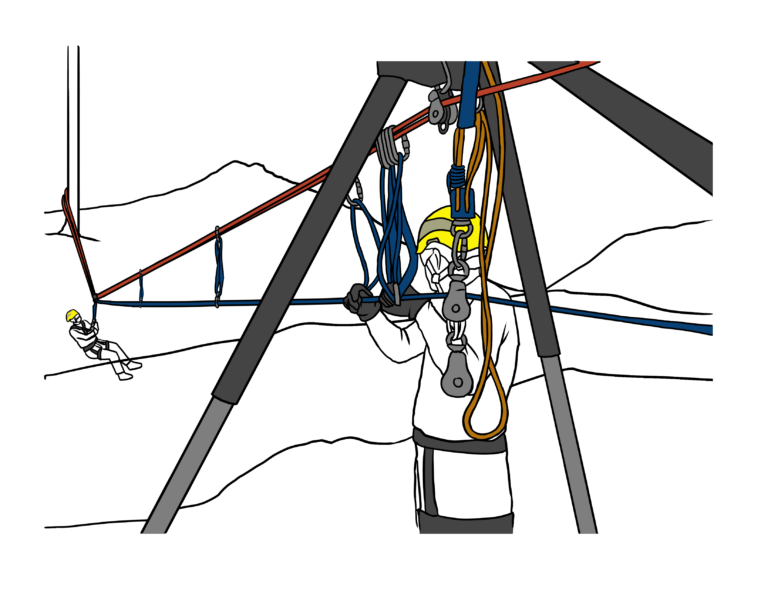

Hands-On Demonstrations:

- Jointly conduct workshops or demonstrations to show proper usage, rigging techniques, and maintenance procedures.

Maintenance and Inspection Workshops:

- Regularly organize sessions focused on inspection protocols and basic repairs. This ensures that both riggers and trainers can extend the life of equipment while maintaining safety.

Real-World Applications: The Benefits of Streamlined Coordination

- Enhanced Safety: Coordinated efforts reduce the risk of gear malfunctions and operator errors, ensuring smoother rescues.

- Cost Efficiency: By eliminating unnecessary purchases and prolonging gear life, departments save resources.

- Skill Development: Collaborative training ensures teams are proficient with the latest tools and techniques, improving response effectiveness.

- Modernized Operations: Phasing out outdated gear and techniques ensures teams are ready for contemporary challenges.

Conclusion

To build effective technical rescue operations, we must focus on removing obsolete tools and techniques while fostering collaboration among stakeholders. This ensures teams are equipped with the right tools, knowledge, and strategies for success. By prioritizing open communication, inclusive decision-making, and continuous improvement, technical rescue teams can elevate their operations to meet modern challenges.

Suggested Links

Peace on your Days

Lance