The Mechanical Advantage Piggyback Method is a groundbreaking rigging technique in rope rescue operations, designed to navigate knots effectively while maintaining system stability and load control. This advanced method shines in scenarios involving mechanical devices such as the Clutch or MPD, utilizing a secondary mechanical advantage system like the AZTEK to ensure seamless and efficient knot management.

Understanding the Mechanical Advantage Piggyback Method

In the high-stakes environment of rope rescue, every knot, load, and motion must be precise. The Mechanical Advantage Piggyback Method allows rescuers to handle knots without interrupting the system’s operation. This approach creates a temporary load-bearing secondary system, enabling teams to reconfigure and adjust the primary system safely and efficiently.

How the Method Works: A Narrative Overview

Imagine you’re mid-operation, hauling a critical load when a knot approaches the Clutch, threatening to disrupt the smooth progress. With the Mechanical Advantage Piggyback Method, your team has a plan.

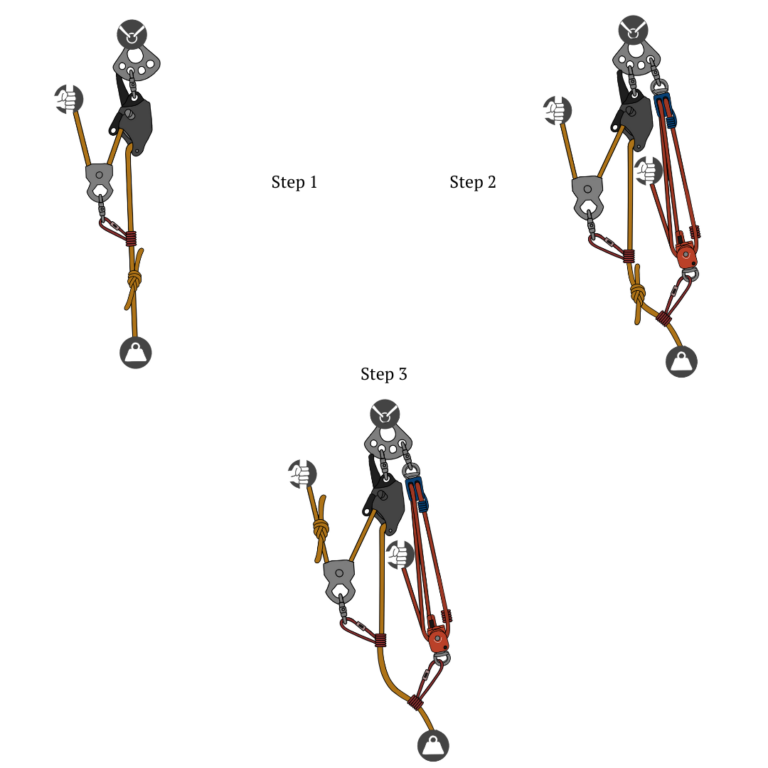

You begin by halting the load’s movement just before the knot reaches the Clutch. The Clutch handle is rotated to ‘Stop,’ temporarily securing the load. At this moment, a secondary system—the piggyback setup—is connected to a reliable anchor point. This system, typically involving a Prusik hitch, attaches to the main rope, forming a backup ready to shoulder the load.

As the team works, the piggyback system comes into play, bearing the load and allowing the primary system to be reconfigured. The knot is carefully repositioned past the Clutch while the secondary system maintains control. Once the knot is clear, the tension is gently transferred back to the Clutch, ensuring a smooth and uninterrupted operation.

Key Benefits

- Seamless Knot Handling

- The piggyback system facilitates uninterrupted operations, ensuring knots do not hinder the functionality of critical devices like the Clutch or MPD.

- Enhanced Safety

- Employing a secondary system reduces risks, offering an additional layer of control during delicate transitions.

- Flexibility Across Scenarios

- This method adapts to various devices and configurations, providing a versatile solution for different rescue operations.

Why This Method Matters

The Mechanical Advantage Piggyback Method goes beyond being a technical procedure; it embodies the principles of innovation and safety in rope rescue. It highlights the importance of planning, adaptability, and the use of advanced tools like the AZTEK. By mastering this method, rescue teams ensure efficiency and reliability, safeguarding both the operation and the individuals they are assisting.

Whether you’re navigating a precarious high-angle rescue or managing a complex urban scenario, the Mechanical Advantage Piggyback Method stands as a testament to the ingenuity and precision of modern rope rescue techniques.

(Relevant Rigging Lab Academy resources):

- Understanding the AZTEK System for Rescue Operations

- Discusses the role of AZTEK in technical rope systems, enhancing understanding of secondary mechanical advantage.

- The Role of the Clutch in Modern Rope Rescue

- Explores the features and applications of the Clutch, a critical device for piggyback methods.

- Essential Techniques in High-Angle Rope Rescue

- Covers advanced techniques like the piggyback method in high-angle rescue scenarios.

(Gear from Rescue Response Gear):

- Buy the Clutch Rope Device

- For reliable rope management during rescue operations.

- Purchase the AZTEK Pulley System

- Ideal for secondary mechanical advantage and piggyback systems.

Peace on your Days

Lance