Key Safety Factors in Rope Rescue: Understanding Limits and Dynamic Safety

In rope rescue, using precise terminology for safety factors and equipment strength can prevent misunderstandings and unsafe assumptions. Here’s a practical guide for accurately applying safety factors without relying on misleading comparisons to fields like aerospace or civil engineering.

Understanding Safety Factors (FoS) vs. Static System Safety Factor (SSSF) in Rope Rescue

Safety factors in engineering account for unknowns in load, stress, and wear over time. In rope rescue, the commonly used Static System Safety Factor (SSSF) estimates system strength under static loads. However, comparisons between SSSF and FoS in aircraft or structural engineering don’t apply here. Unlike controlled conditions in other industries, rope rescue requires a flexible approach that aligns with unpredictable field conditions.

Static vs. Dynamic Load in Rope Rescue Safety

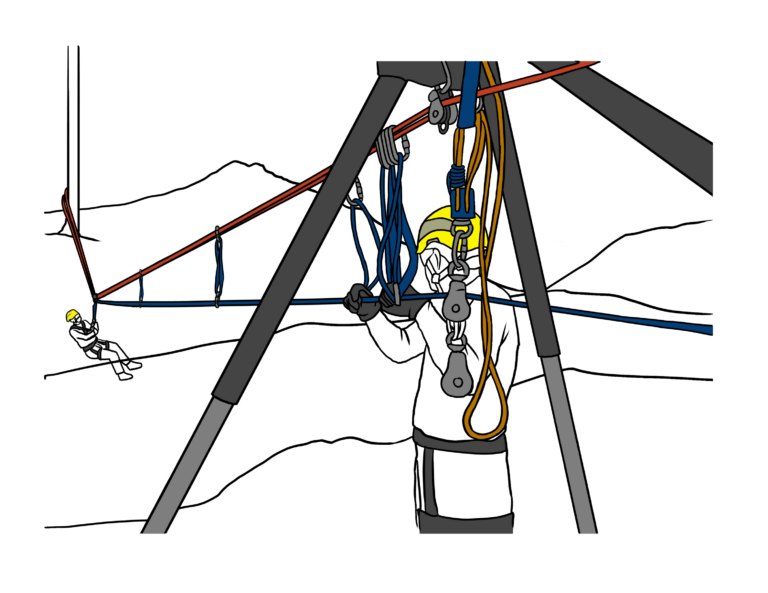

Rope rescue systems frequently face dynamic loads, where forces can change rapidly during events like falls or sudden jerks. Static loads are constant and predictable, making static safety factors inadequate for dynamic rescue environments. Dynamic Safety Factors better reflect real-world scenarios, where forces shift and vary. This approach ensures a more accurate safety assessment in any rescue setup.

Why Comparisons to Aerospace and Civil Engineering Can Mislead

Claims that rescue systems have a “safety factor of 10:1” or are as overbuilt as aircraft can mislead. Aerospace safety margins, for example, prevent specific failure modes in controlled, repeatable conditions, while rope rescue faces unpredictable environments. Rope rescue gear is typically tested under lab conditions, but these settings do not replicate the diversity of real rescue scenarios. Load assessments should always consider the unique factors of each environment, such as confined spaces or mountain rescues.

Testing and the Role of Field Experience

Lab testing of rope rescue equipment provides essential insights but can’t simulate every field condition. Ratings, such as “24kN,” reflect lab-tested strength but may not equate to real-world safety. Practical safety assessments rely on testing experience, observed performance in varied conditions, and understanding potential failure points. Field experience is essential to go beyond simple ratings, adapting safety evaluations to real rescue demands.

Recommendations for Accurate Safety Evaluations

For better safety evaluations, use Dynamic Safety Factors that capture the unpredictable forces in rescue work. Replacing SSSF with terms like Static Strength Ratio (SSR) offers a clearer perspective. Ultimately, rope rescue safety should depend on assessments that weigh the environment, potential dynamic events, and equipment specifics, not only static ratios.

Final Thoughts

Accurate safety in rope rescue means moving beyond simple ratios to reflect the dynamic forces and diverse environments that define rescue scenarios. By focusing on realistic, environment-based assessments and using terms that reflect real-world conditions, rescue teams can ensure safer, more effective setups that meet the specific demands of each mission.

Here are some relevant articles from Rigging Lab Academy’s blog that align with the topic of safety factors and dynamic loading in rope rescue:

- Pulleys and Progress Capture Devices

- This article discusses the role of pulleys and progress capture devices in creating safe mechanical advantage systems, which are essential for managing load and force in rescue operations.

- Complex Mechanical Advantage Systems

- Covers the complexities and setup of mechanical advantage systems, highlighting the importance of understanding load dynamics for safe operation in heavy-load rescues.

- Basic Mechanical Advantage Systems in Rescue Operations

- A guide to the fundamentals of mechanical advantage systems, including static and dynamic forces, offering a foundation for understanding load-bearing and system stability in rescue scenarios.

- Multi-Point Anchors in Rescue

- This article explores multi-point anchoring setups, emphasizing stability and load distribution in complex rescue operations.

- Knots and Force Multipliers in Anchor Systems

- Focuses on knots and force-multiplying systems in rescue rigging, crucial for managing load forces and ensuring secure anchor setups in dynamic environments.

These articles offer valuable information on key aspects of load management, mechanical advantage, and anchoring in rope rescue, aligning with the principles of accurate safety assessments in dynamic rescue settings.

Peace on your Days

Lance