Friction in Mechanical Advantage Systems

Friction is an unavoidable yet often underestimated factor in mechanical advantage (MA) systems. While MA systems are designed to amplify force, the presence of friction can significantly diminish their theoretical efficiency. Understanding how friction arises, its impacts, and methods to mitigate it is crucial for ensuring the success and safety of rope rescue operations.

This blog explores the nuances of friction in mechanical advantage systems, supported by practical examples, best practices, and real-world data.

What Is Friction in MA Systems?

Friction, in the context of MA systems, refers to the resistance encountered as ropes interact with surfaces, devices, and hardware. It affects the system by reducing the theoretical output of force amplification. For example, a 3:1 system may only function as a 2:1 system if friction is not properly managed.

- Theoretical Efficiency: The calculated advantage assumes no energy loss.

- Real-World Efficiency: Friction, wear, and rope interaction with devices and edges reduce efficiency.

Primary Sources of Friction in MA Systems

- Contact Points on Ropes and Edges:

- Rope rubbing against rock, concrete, or protective padding creates significant resistance.

- A 90-degree bend over an edge can introduce up to a 50% loss in efficiency, depending on surface material.

- Pulley Systems:

- Low-quality or non-sealed pulleys may operate at 50-70% efficiency, reducing overall mechanical advantage.

- Even high-efficiency pulleys (e.g., sealed ball-bearing types) have some inherent resistance, usually resulting in 90-95% efficiency.

- Progress Capture Devices (PCDs):

- Devices like the Petzl Rescucender or tandem Prusik hitches add friction while locking the load.

- These elements, while crucial for safety, further diminish the system’s output.

- Mechanical Rope Bends:

- Any time a rope bends through a device or anchor point (e.g., 180 degrees around a carabiner), resistance increases significantly.

- Environmental Factors:

- Wet, icy, or dirty ropes and components can introduce additional friction, reducing system efficiency and increasing wear.

How Friction Impacts Mechanical Advantage Systems

In theory, an MA system amplifies force to reduce the effort required to move a load. However, friction alters this equation:

- 3:1 System Example:

- Theoretically, 33 lbs. of input force should lift a 100-lb. load.

- In reality, friction at edges, pulleys, and PCDs may require 50 lbs. or more of input force.

- Cumulative Friction:

- Each friction point in the system compounds the total resistance.

- For instance, combining a rough edge (50% efficiency) with a low-quality pulley (70% efficiency) reduces overall system efficiency to 35%.

- Safety Considerations:

- Increased friction also creates greater load on anchor points and ropes, which can lead to equipment wear or failure if not properly accounted for.

Real-World Data on Friction

Recent tests from rigging organizations, including field data from rope rescue professionals, reveal:

- Pulley efficiency ranges from 70% (bushings) to 90%+ (sealed bearings).

- Rope bending over sharp edges reduces efficiency by up to 50% depending on angle and surface material.

- Tandem Prusiks and similar progress capture systems introduce 10-15% additional resistance.

These findings highlight the importance of evaluating each component in your MA system for its contribution to overall friction.

Mitigating Friction in Mechanical Advantage Systems

- High-Efficiency Pulleys:

- Use sealed ball-bearing pulleys like the CMC Clutch or Petzl Spin Pulley to reduce resistance at key points.

- Edge Protection:

- Install edge rollers, pads, or sliders to reduce friction where ropes encounter sharp or abrasive surfaces.

- Anchor Management:

- Minimize sharp bends in ropes by carefully selecting anchor points and routing.

- Use wide-radius carabiners or rigging plates to improve rope alignment.

- Proper Equipment Maintenance:

- Clean and lubricate pulleys and devices regularly to maintain peak performance.

- Inspect ropes for contaminants or damage that could increase friction.

- Efficient System Design:

- Evaluate your entire system for unnecessary friction points.

- Avoid overloading components like Prusik hitches, which can increase resistance when under excessive tension.

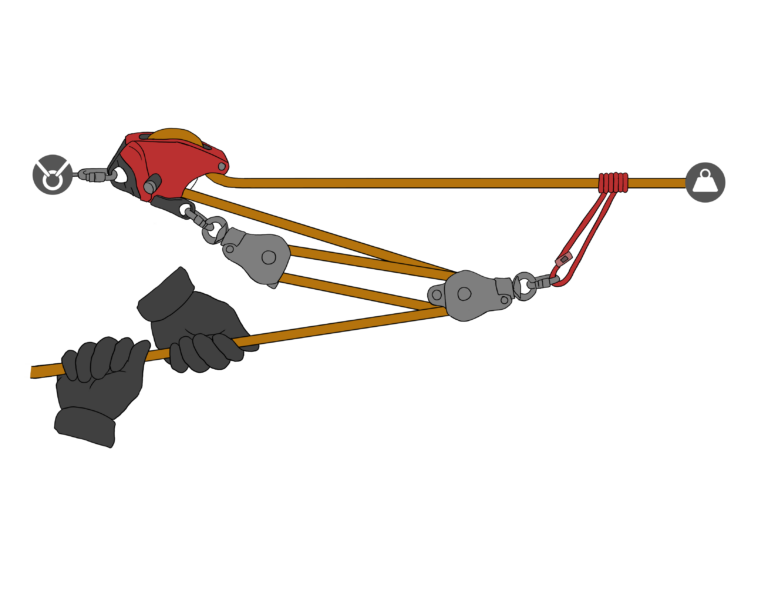

Practical Examples

- Vertical Hauling:

- A 3:1 Z-Drag with suboptimal pulleys and a tandem Prusik PCD might yield less than a 2:1 advantage, requiring far greater input force.

- Adding sealed-bearing pulleys and reducing rope-on-edge contact can improve efficiency to near 3:1.

- Raising a Litter:

- Hauling a litter across uneven terrain introduces significant friction at rope transitions. Using edge rollers can minimize effort and protect ropes.

- Rope Rescue in Extreme Conditions:

- Wet or icy conditions magnify friction losses. Field tests show up to a 25% reduction in efficiency compared to dry systems, emphasizing the need for high-quality gear.

Conclusion

Friction is an unavoidable factor in mechanical advantage systems, but with careful planning and the right equipment, its impact can be minimized. By understanding the sources of friction and incorporating high-efficiency components like sealed pulleys, edge protection, and well-maintained ropes, rescue teams can optimize their systems for safety and performance.

Practical knowledge of friction allows rescuers to bridge the gap between theoretical and real-world mechanical advantage, ensuring effective and efficient operations in any scenario.