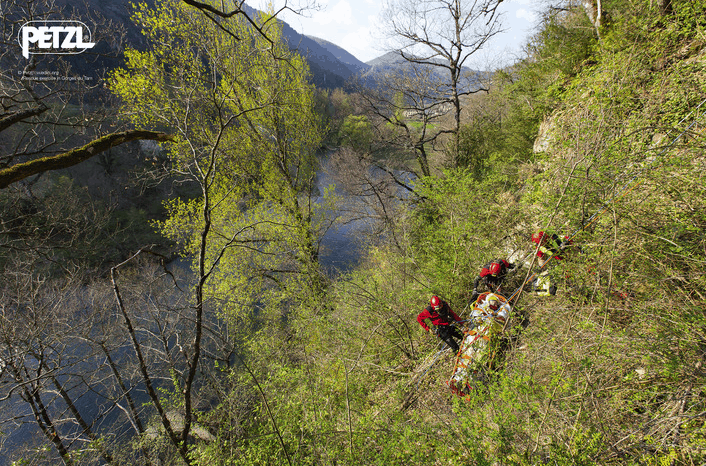

Choosing Carabiners for Hauling Systems

The choice of carabiners plays a critical role in the efficiency, safety, and alignment of hauling systems and pulley attachments. Carabiners are more than connectors—they ensure load stability, reduce friction, and maintain system integrity during operation.

This guide covers best practices for selecting carabiners, key considerations, and recommendations for optimizing performance in hauling systems.

Key Considerations When Selecting Carabiners

When choosing carabiners for hauling systems, three primary factors come into play:

- Efficiency

- Pulleys perform best when paired with carabiners that minimize friction and maintain proper alignment.

- Compatibility

- Carabiners must fit seamlessly with the equipment they connect, including pulleys with wide attachment points or devices like progress capture systems.

- Load Management

- Positioning the load-bearing element on the spine side of the carabiner maximizes strength and stability while reducing stress on the gate.

Recommended Carabiner Types for Hauling Systems

Different carabiner shapes serve specific purposes in rigging. Here’s an overview of the best types for hauling systems:

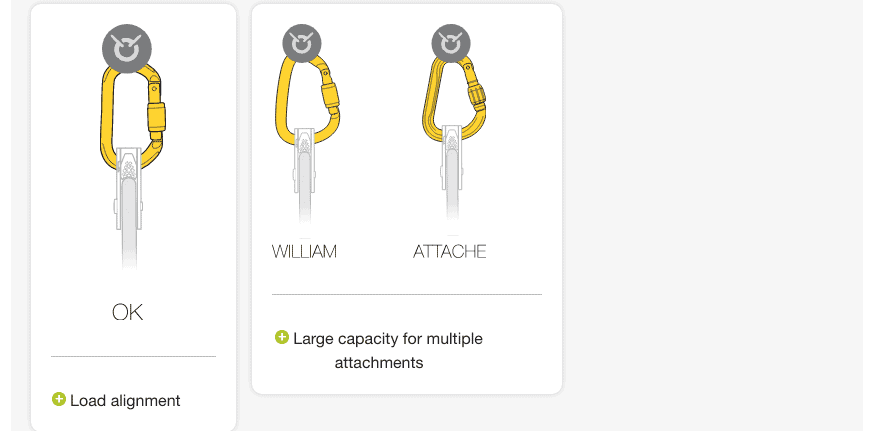

1. Symmetric Shape Carabiners

- Why Choose Symmetric Carabiners?

The symmetric shape of carabiners, such as the OK, provides excellent load alignment. This is particularly effective when used with pulleys that have widely spaced side plates or devices with large attachment holes like the PRO TRAXION.- Key Benefit: Maximizes efficiency by reducing friction and ensuring smooth load distribution.

2. Pear-Shaped Carabiners

- Why Choose Pear-Shaped Carabiners?

Carabiners like the WILLIAM and ATTACHE feature a pear shape, which allows for the attachment of multiple ropes or devices at a single point. This makes them ideal for complex hauling systems requiring versatile connections.- Key Benefit: Flexibility for multi-rope setups and anchor management.

Explore More at Rigging Lab Academy

- Comprehensive Guide to Carabiner Selection

- Hauling Systems and Pulley Configurations

- Petzl Carabiner Range

Best Practices for Carabiner Use

To ensure both safety and longevity of your rigging system, follow these precautions:

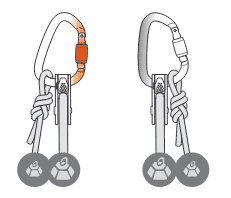

- Lock and Position Check

- After installation, confirm that all carabiners are locked and properly oriented before putting the system under load.

- Avoid Friction and Rubbing

- Monitor the carabiner’s position during hauling to prevent rubbing against sleeves, ropes, or hard edges, which can lead to wear or misalignment.

- Load Placement

- Place the primary load on the spine side of the carabiner. The gate side should be reserved for secondary attachments to maintain strength and reduce stress.

Recommendation on carabiner and accessories

Why this choice?

• The symmetric shape of the OK provides good load alignment, even with pulleys having widely spaced side plates or devices with rather wide attachment holes such as the PRO TRAXION

• The pear shape of the WILLIAM and ATTACHE allows several ropes or items to be connected in one place

Essential Risks to Consider in Hauling Systems

When selecting carabiners and building pulley systems, consider these critical risks:

- Misalignment: Improper carabiner orientation can create weak points in the system.

- Friction: Excessive rubbing can wear equipment and compromise efficiency.

- Gate Loading: Placing the primary load on the gate side reduces the carabiner’s strength.

Proper selection and consistent safety checks can mitigate these risks and improve the overall integrity of your hauling system.

Final Thoughts

Choosing the right carabiner for hauling systems and pulley attachments is essential for both safety and efficiency. By focusing on compatibility, alignment, and load management, you can optimize your rigging setup for high performance in demanding conditions.

Recommended Carabiners:

- OK Carabiner for symmetrical load alignment.

- WILLIAM and ATTACHE Carabiners for versatility and multi-rope connections.

Investing in quality carabiners and following best practices ensures smoother operations, reduced risks, and long-lasting performance in any hauling system.

Explore More at Rigging Lab Academy:

- Comprehensive Guide to Carabiners

- Hauling Systems and Pulley Configurations

- Petzl Carabiner Range

Peace on your days,

Lance

8 thoughts on “Choice of Carabiners for Hauling Systems”

295820 604378You wouldnt feel it but Ive wasted all day digging for some articles about this. You might be a lifesaver, it was an superb read and has helped me out to no finish. Cheers! 469403

902521 500432Couldn?t be developed any far better. Reading this post reminds me of my old room mate! He always kept talking about this. I will forward this report to him. Pretty certain he will possess a good read. Thanks for sharing! 756450

785615 796058I genuinely enjoy looking at on this site , it has fantastic content . 820173

438362 826326Some really fascinating information , well written and broadly speaking user pleasant. 36

Perfect piece of work you have done, this internet site is really cool with superb information.

Wow! At last I got a blog from where I know how to in fact get useful facts regarding my study and knowledge.

Enjoyed looking at this, very good stuff, thanks.

209247 206801Aw, this was an exceptionally nice post. In concept I would like to location in writing such as this moreover – spending time and actual effort to create a superb article but so what can I say I procrastinate alot via no indicates discover a method to go completed. 533234

Comments are closed.