Building Maintenance Rope Descent Safety

Building Maintenance Rope Descent Safety – Rope descent systems are essential for building maintenance, ensuring safe access to high structures for tasks like window cleaning and façade inspections. Proper use of these systems requires adherence to NFPA 1006: Standard for Technical Rescue Personnel Professional Qualifications (2021) and industry best practices. This guide covers essential equipment, descent techniques, hazard mitigation, and partner rescue strategies, ensuring compliance and efficiency in rope-based work environments.

Equipment for a Rope Descent System

A well-equipped rope descent system includes personal protective equipment (PPE) and operational gear designed to enhance worker safety and maneuverability.

1. Personal Equipment for Descent and Positioning

- Harness – A full-body harness with ventral and dorsal attachment points ensures both secure positioning and fall protection. Must meet EN 361 and EN 813 standards.

- Work Seat – Designed for prolonged suspension comfort but not classified as PPE. Must always be used with a harness.

- Descender – Devices like ID’S, ID’L, or RIG enable controlled movement and prevent sudden falls.

- Mobile Fall Arrester – Independently installed on a separate rope to activate in case of primary system failure. Common devices include ASAP or ASAP LOCK.

- Positioning Lanyard – Used for temporary securing at a workstation to improve ergonomic positioning. Adjustable versions like GRILLON offer precision.

- Additional PPE – Helmets with chinstraps, gloves with grip enhancement, ANSI-certified eye/face protection, and weather-appropriate clothing reduce environmental risks.

2. Mutual Checking of Team Members (Partner Check)

Before exposure to height, mutual verification is critical to prevent equipment failures or human error.

- Before Exposure:

- Confirm anchors are properly installed and can bear load requirements.

- Inspect rope paths and rope length for clearance and safety.

- Review the rescue plan to ensure emergency preparedness.

- Pre-Work Equipment Check:

- Verify harness straps are correctly fastened and adjusted.

- Ensure descenders, fall arresters, and lanyards are securely attached.

- Check helmets for proper fit and chinstrap engagement.

- Final Inspection:

- Confirm all connectors are locked and attached to correct anchor points.

- Inspect tools and equipment for secure attachment to prevent drops.

3. Anchoring Ropes

Rope anchoring is essential for maintaining system stability and ensuring redundancy. Various anchor configurations exist:

- Temporary Adjustable Anchors – Wrapped around beams, pipes, or structures for a secure tie-in. PROTEC sleeves help prevent abrasion.

- Load-Sharing Anchors – Distribute force across multiple points to reduce strain on a single anchor. Bunny knots or equalized slings help balance forces.

- Rope Protection Measures – Edge rollers, rope sleeves, and anchor extensions prevent excessive friction.

- Damaged Rope Isolation – Use butterfly knots to bypass compromised sections safely.

Descent Techniques

1. Descending Techniques

- Always maintain a grip on the brake side of the rope to control speed.

- Use descender-specific braking systems to manage friction efficiently.

- Always pair with an independent fall-arrest system for redundancy.

2. Adding Friction During Descent

Extra friction provides better control, especially in:

- Long descents, where rope heat buildup can reduce braking effectiveness.

- Wet or icy conditions, increasing the risk of slippage.

- Carrying heavy loads, which can accelerate descent speed unexpectedly.

- Solutions include FREINO carabiners, additional rope wraps, or redirected friction through braking systems.

3. Precise Positioning with Two Sets of Ropes

Using two independent rope systems minimizes swing risks and improves precision:

- Each rope should include a separate progression and fall-arrest rope.

- Triangulation techniques allow precise lateral movement along a façade.

- Protect ropes from abrasion by using PROTEC sleeves or edge rollers.

4. Occasional Ascent

While ascending is energy-intensive, short climbs may be necessary.

- Handled ascenders and footloops provide controlled upward movement.

- A CROLL chest ascender aids efficiency for vertical ascents.

- Tethered ascenders prevent accidental tool drops.

5. Risk of Falling Tools

Dropped tools are a major hazard. Best practices include:

- TOOLBAG storage pouches securely attached to the harness.

- Retractable tool lanyards prevent falling objects from injuring those below.

- Regular tool inspections ensure all items are securely fastened.

Problems Related to Long Descents

1. Rope Stretch

- Low-stretch ropes (AXIS or VECTOR) elongate 3–8% under varying loads.

- Excessive stretch reduces precision and increases fall clearance requirements.

- Solution: Install descenders on both ropes and operate them simultaneously to minimize stretch.

2. The Effect of Wind on Ropes

- Wind can create slack, increasing the risk of uncontrolled movement.

- Unstable ropes may increase fall distances if the system lacks tension.

- Solution: Use ASAP LOCK to limit rope movement or secure rope ends with weighted attachments.

Partner Rescue: A Lifesaving Necessity

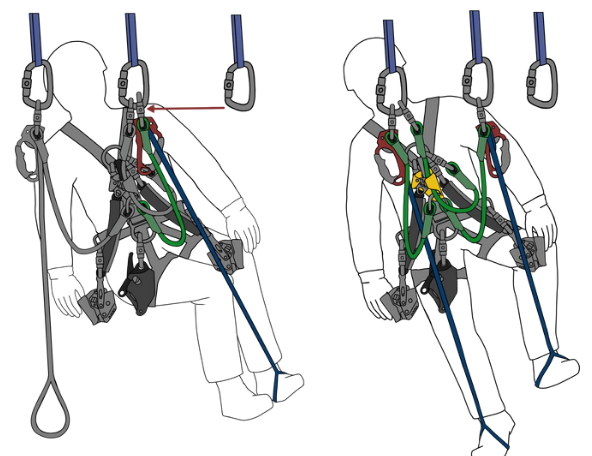

A well-executed pick-off and tandem descent rescue prevents suspension trauma and ensures quick evacuation.

Steps for Partner Rescue:

- Establish a secure connection with a long lanyard to stabilize the victim.

- Transfer the victim’s weight onto the rescuer’s descent system using a secure attachment.

- Ensure proper anchoring before disconnecting from the original rope system.

- Execute a tandem descent with controlled braking techniques to lower safely.

Using ASAP’SORBER AXESS enhances safety by accommodating two-person loads up to 250 kg, following NFPA 1006 protocols.

Conclusion

Rope descent systems are indispensable in building maintenance and industrial access. Workers must master proper equipment use, descent techniques, and rescue protocols to maintain high safety standards. By following NFPA 1006 guidelines, teams can significantly reduce risks and improve operational performance. Organizations should invest in ongoing training, safety audits, and advanced equipment to enhance high-altitude work efficiency and safety.

For expert guidance, explore Petzl’s Building Maintenance Rope Descent System and NFPA 1006 resources to stay updated on best practices in vertical access safety.

Peace on your Days

Lance