Rigging Horizontal Traverse Lines: Optimal Height, Safety, and Techniques

Optimal Height for Horizontal Traverse Lines

When rigging horizontal traverse lines, the height at which the line is positioned can significantly impact safety, efficiency, and functionality. Following some general guidelines can help ensure the line is placed correctly.

Recommended Height Placement

The preferred height for a horizontal traverse line is typically at or slightly above chest level. This height offers several advantages:

- Ease of Use: Positioning a horizontal traverse line at chest height allows for comfortable movement along the traverse. It reduces strain on the body, making it easier for workers to navigate the system without excessive bending or stretching. If the line is too low, users may have to hunch over, increasing fatigue and discomfort. Conversely, if the line is too high, it can cause users to overreach, leading to a potential loss of balance. Chest-height lines strike a balance, allowing for natural posture during use. This positioning also makes it easier to clip in and out of the system, reducing time and effort required to secure oneself to the traverse line.

- Safety: Safety is a primary concern in any rigging system. The height of a traverse line plays a crucial role in minimizing risks. Positioning the line at chest height reduces the risk of users falling below the line, which could result in a dangerous pendulum swing. Pendulum swings occur when a person falls while connected to a traverse line and swings back and forth, potentially hitting obstacles or the ground. Keeping the line at chest height ensures that users remain above the line, reducing the likelihood of such incidents. Additionally, this height provides better control during rescue operations, as rescuers can easily access and stabilize individuals on the line.

- Clearance: Maintaining adequate clearance above obstacles is essential for the safe operation of horizontal traverse lines. Chest-height lines provide a practical balance between ground clearance and accessibility. When lines are too low, they may come into contact with rocks, trees, or equipment, increasing the risk of damage or injury. Proper clearance ensures that the line remains free from interference, reducing wear and tear on the system and improving its longevity. In environments with uneven terrain, riggers should carefully assess the line’s height to ensure consistent clearance throughout the traverse path. This consideration is particularly important in rescue scenarios, where smooth movement along the line is critical.

Safety Considerations for Traverse Line Height

Safety should always be the primary consideration when determining the height of a horizontal traverse line. Here are some critical factors to keep in mind:

- Anchor Points: Anchor points must be positioned at a height that allows the traverse line to be rigged at the desired level, typically at chest height. The stability and strength of anchor points are essential to ensure they can withstand the forces exerted by the system. These forces include the weight of users and any dynamic loads generated during movement or falls. Anchor points should be inspected thoroughly before use to ensure they are secure and free from defects. Natural anchors, such as trees or rocks, must be assessed for strength and stability. Artificial anchors, such as bolts or plates, should be installed according to industry standards to handle required loads.

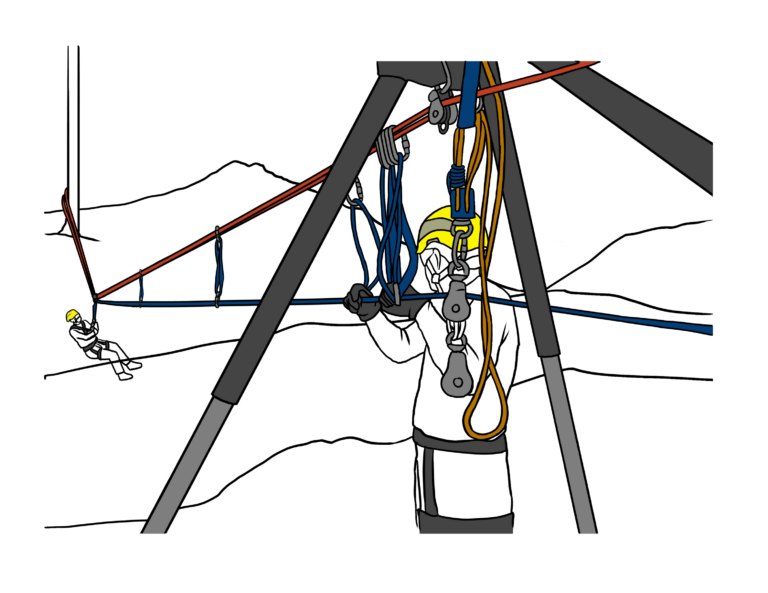

- Elevation Adjustment: When anchor points are too low, riggers can use A-frames or other structures to elevate them. A-frames provide additional height for anchor points, allowing the traverse line to be rigged at the optimal level. Properly constructed A-frames significantly improve the safety and functionality of a traverse line by maintaining clearance and minimizing sag.

- Line Tensioning: Proper tensioning of the traverse line is crucial for stability and safety. A poorly tensioned line can sag excessively, reducing clearance and increasing the risk of contact with obstacles. An overly tight line can put undue stress on anchor points and equipment, increasing the likelihood of failure. Riggers should use mechanical advantage systems, such as pulley systems or tensioning devices, to achieve the appropriate tension. Regular checks and adjustments are necessary to ensure the line remains taut and secure.

- Mechanical Advantage Systems: Mechanical advantage systems use pulleys and ropes to multiply the force applied by the rigger. For example, a 3:1 system allows the rigger to apply three times the force exerted on the rope. These systems make it possible to tension long traverse lines without excessive physical effort. They also provide greater control over tension adjustments, allowing riggers to fine-tune the line’s tension to meet safety requirements.

- Clearance from Obstacles: Ensuring adequate ground clearance is essential for safe operation. The line should be high enough to prevent users from coming into contact with the ground or obstacles during movement or a fall. Ground clearance requirements may vary depending on the environment and the type of traverse being performed. In rescue scenarios, the line may need to be higher to accommodate litter movement or other equipment. Riggers should assess the entire traverse path to identify potential hazards and adjust the height accordingly.

- Obstacle Avoidance: Riggers must identify potential hazards along the traverse path, such as rocks, trees, or structures, and ensure the line is positioned to avoid contact. In some cases, it may be necessary to adjust the line’s height or tension to navigate obstacles safely. Proper obstacle avoidance improves safety and reduces wear and tear on the traverse line.

- Backup Systems: Incorporating backup safety measures, such as secondary lifelines or personal fall arrest systems, enhances fall protection in traverse setups. Backup systems provide an additional layer of safety if the primary traverse line fails. These systems can include static or dynamic ropes, energy absorbers, and harnesses.

- Rescue Preparedness: The rigging setup should allow for quick rescue operations. This includes having a clear rescue plan, appropriate equipment, and trained personnel on-site. Riggers should consider rescue scenarios during planning and ensure the system is designed for easy access to users on the line. Rescue preparedness is vital in environments where access to emergency services is limited or delayed.

Here are some suggested RLA links:

- Anchor Points in Rigging Systems: For a deeper understanding of anchor point selection and setup, refer to our article on Anchor Points in Rigging Systems.

- Mechanical Advantage Systems Explained: Learn more about mechanical advantage systems and their applications in rigging by reading Mechanical Advantage Systems Explained.

- Ensuring Safety in Highline Operations: Explore best practices for maintaining safety during highline operations in our post Ensuring Safety in Highline Operations.

- Best Practices for Tensioning Ropes: Discover effective techniques for rope tensioning in our guide Best Practices for Tensioning Ropes.

Peace on your Day

Lance