Timber High Directionals in Rescue Operations

Why Build Timber High Directionals?

When rescue teams respond to emergencies in remote or austere environments, they often face unexpected challenges that require improvisation and adaptability. In these scenarios, modern equipment like the Arizona Vortex may not be available or practical to transport. This is where timber structures—such as A-frames or gin poles—become essential tools in a rescuer’s toolkit.

Imagine a wilderness rescue where a team must navigate steep ravines or rough terrain with no vehicle access. Or consider a disaster zone where infrastructure is damaged, and traditional gear caches are inaccessible. In both cases, the ability to construct a high directional using timber on-site can make the difference between a successful rescue and a stalled operation.

Even in industrial settings, rescue teams may encounter non-standard environments—such as aging structures, scaffolding, or temporary worksites—where it’s more practical to build a custom timber rigging system than rely solely on pre-fabricated gear.

Real-World Scenarios Where Timber High Directionals Are Needed

- Wilderness Search and Rescue (SAR):

- Remote locations with limited gear transport options.

- Disaster Response:

- Earthquake zones or collapsed structures where pre-fabricated systems aren’t accessible.

- Industrial Rescues:

- Temporary worksites, scaffolding, or aging infrastructure where on-the-spot solutions are required.

- Military or Expedition Rescues:

- Operations in extreme environments with minimal gear availability.

- Training Exercises:

- Teaching traditional methods for improvisational rigging as a backup plan when modern gear fails or is unavailable.

In these situations, knowing how to construct a high directional using local resources like timber is a critical skill that expands a rescue team’s capabilities and increases operational success rates. It’s not about replacing modern gear—it’s about having the knowledge and adaptability to respond when traditional solutions are the only option.

In technical rope rescue, high directionals play a critical role in edge transitions, confined space rescues, and lifting operations. While modern artificial high directionals like the Arizona Vortex (AZV) have become the gold standard, traditional timber structures can still provide reliable, low-tech solutions in resource-limited or remote environments. Understanding how to build and stabilize timber high directionals can greatly expand a rescue team’s adaptability.

Traditional Timber High Directionals

Wooden structures, such as A-frames and gin poles, have been used for centuries in rigging and rescue operations. These setups require no specialized equipment, making them a valuable option in environments where modern gear is unavailable.

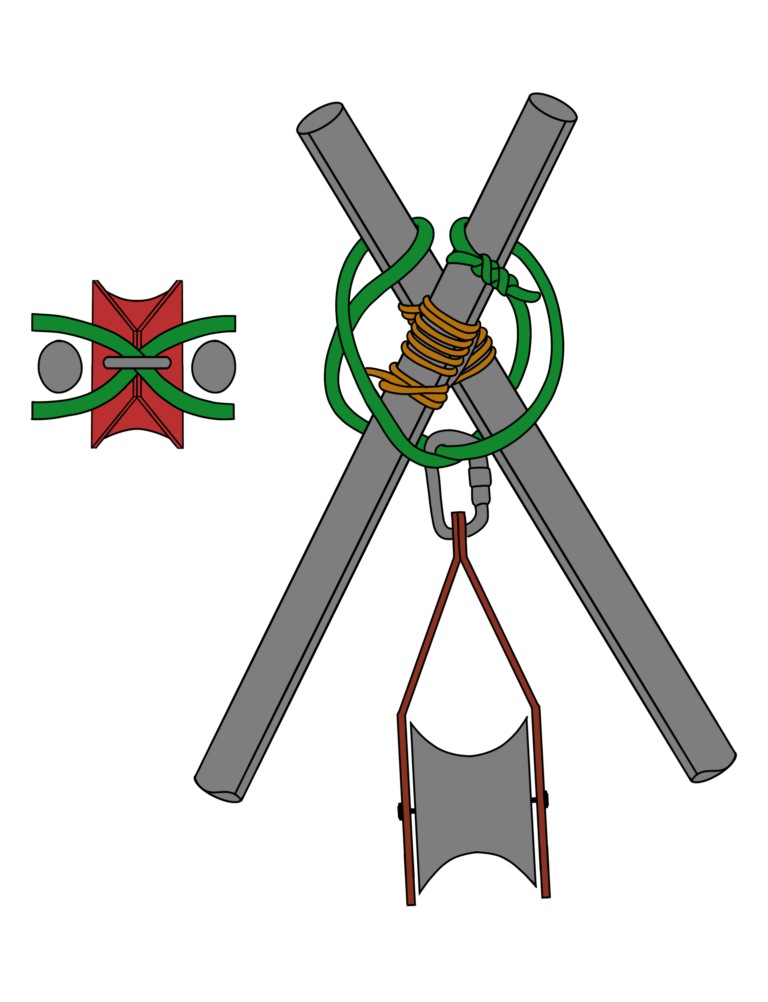

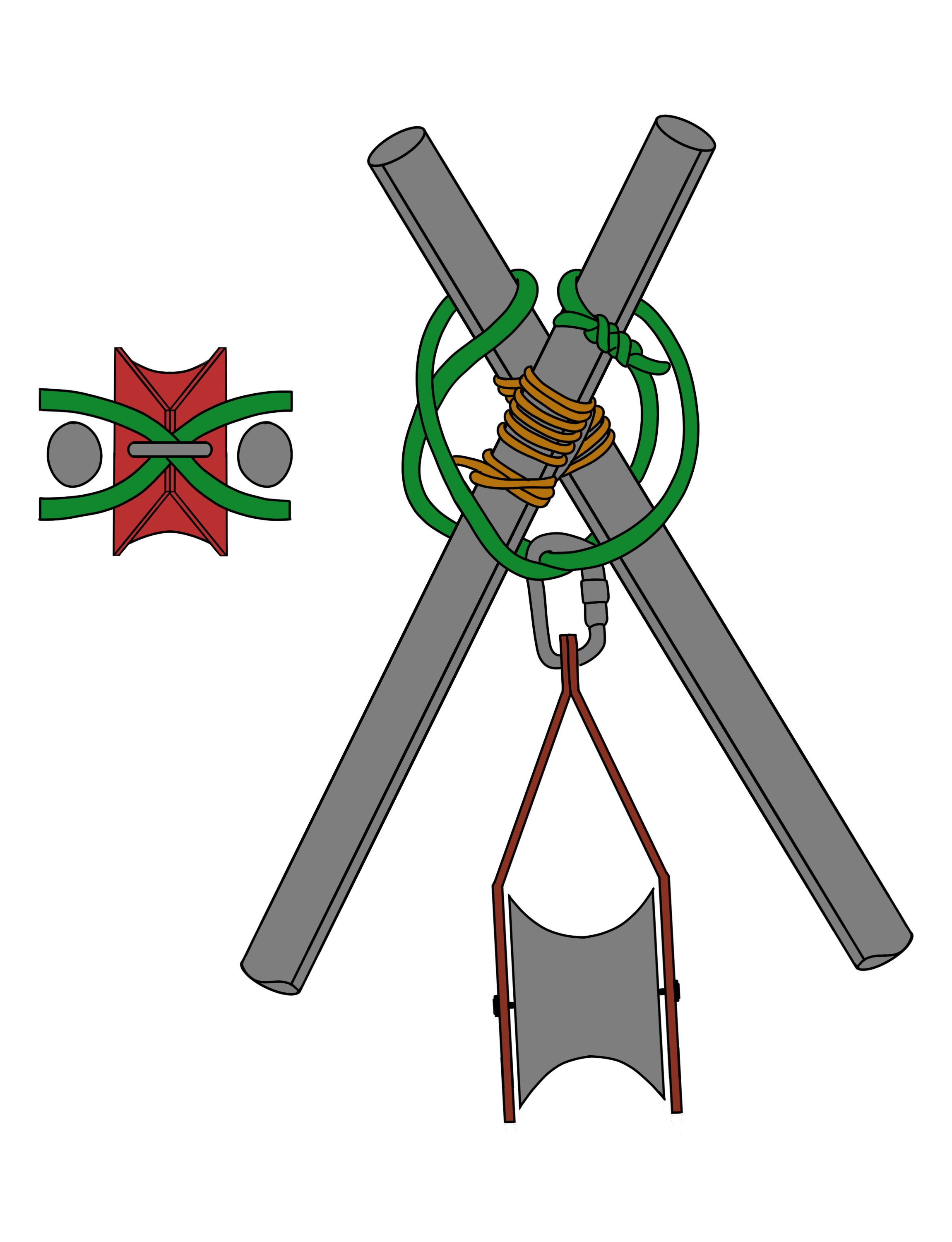

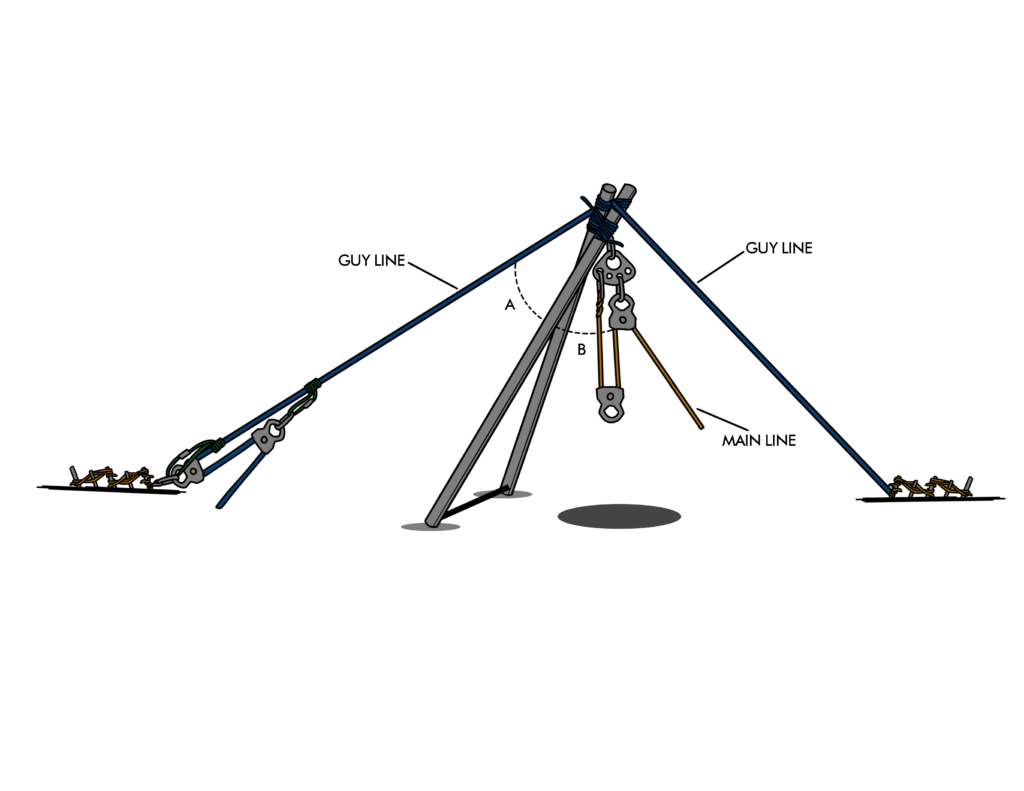

A-Frame Method

The A-frame is one of the simplest and most effective timber-based high directional configurations. Here’s how it’s constructed:

How to Build an A-Frame with Timber:

- Materials Needed:

- Two long, straight timber poles (logs or sturdy tree branches)

- Spacer block (to maintain separation between the legs)

- Ropes or lashings for securing joints

- Construction Steps:

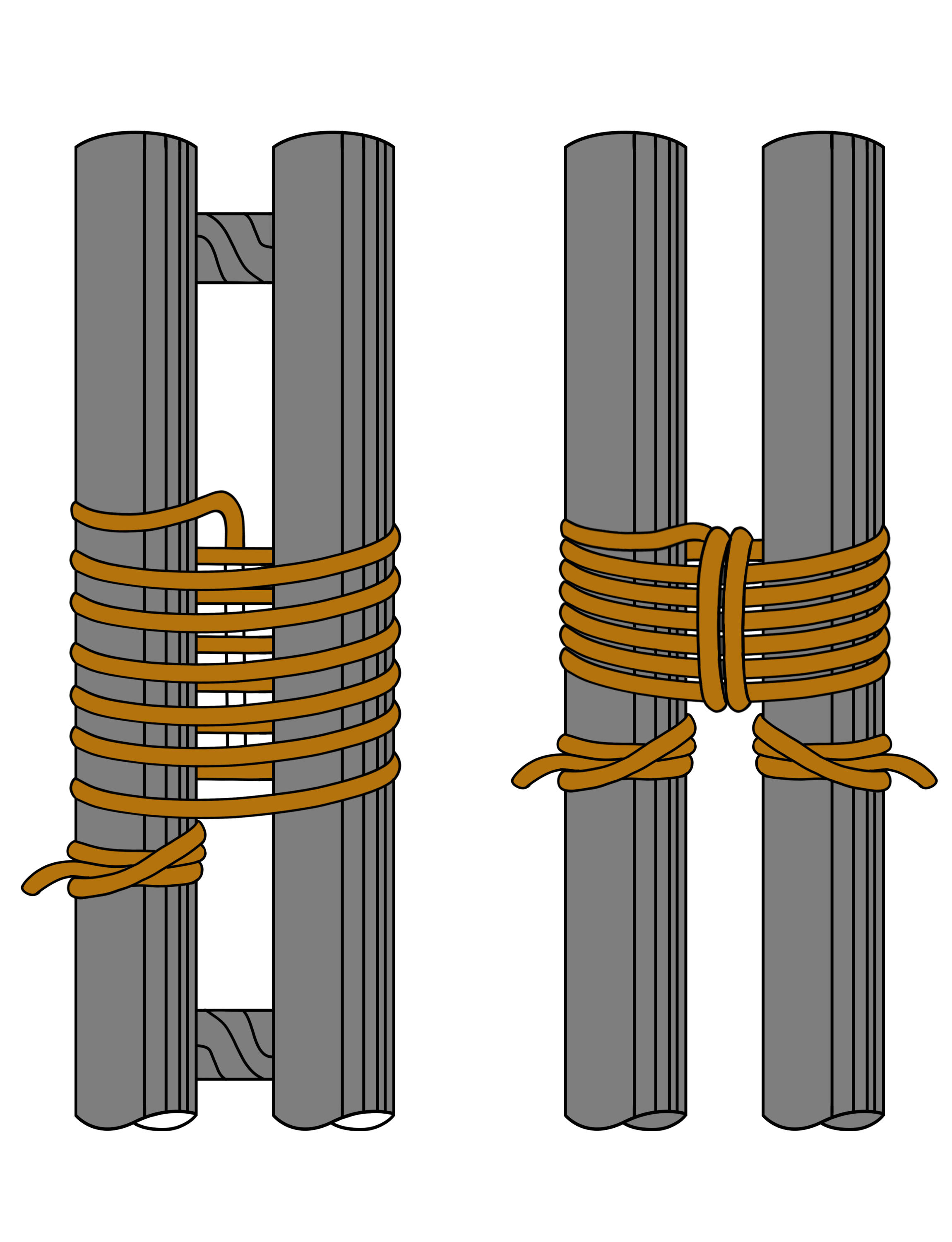

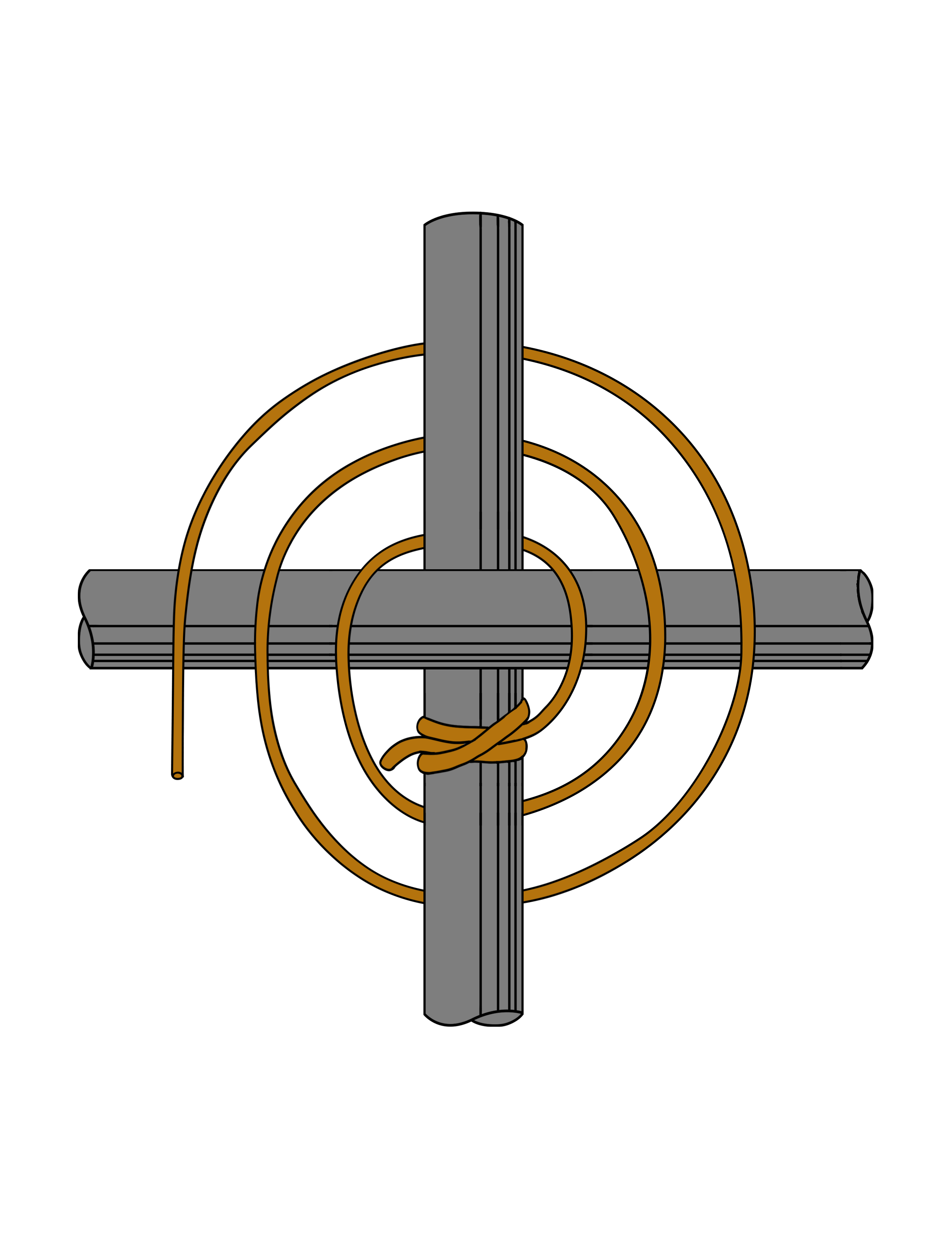

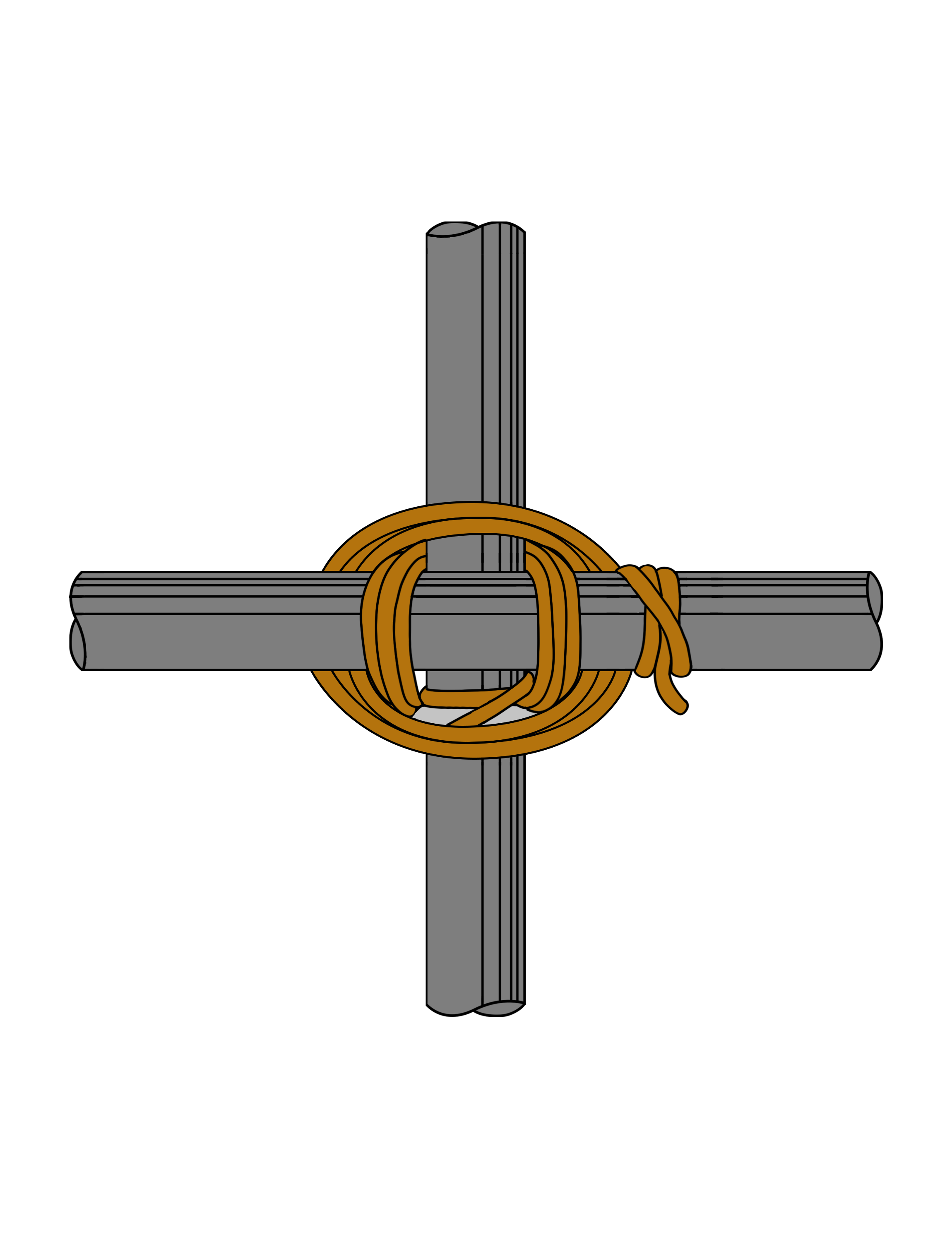

- Lash the Timber Legs Together:

Use round turn lashing to secure the legs at the top. Typically, this involves 10 turns of rope followed by 5 counter-wraps to prevent slipping. - Insert a Spacer Block:

Place a sturdy block between the legs at the apex to ensure stability and prevent the legs from collapsing inward. - Tighten the Lashing:

Drive wooden wedges under the lashings to tighten the structure and increase friction. - Erect the A-Frame:

Once secured, the A-frame can be raised and positioned near the edge of a rescue site, with ropes and rigging attached to the apex.

- Lash the Timber Legs Together:

Gin Pole Technique

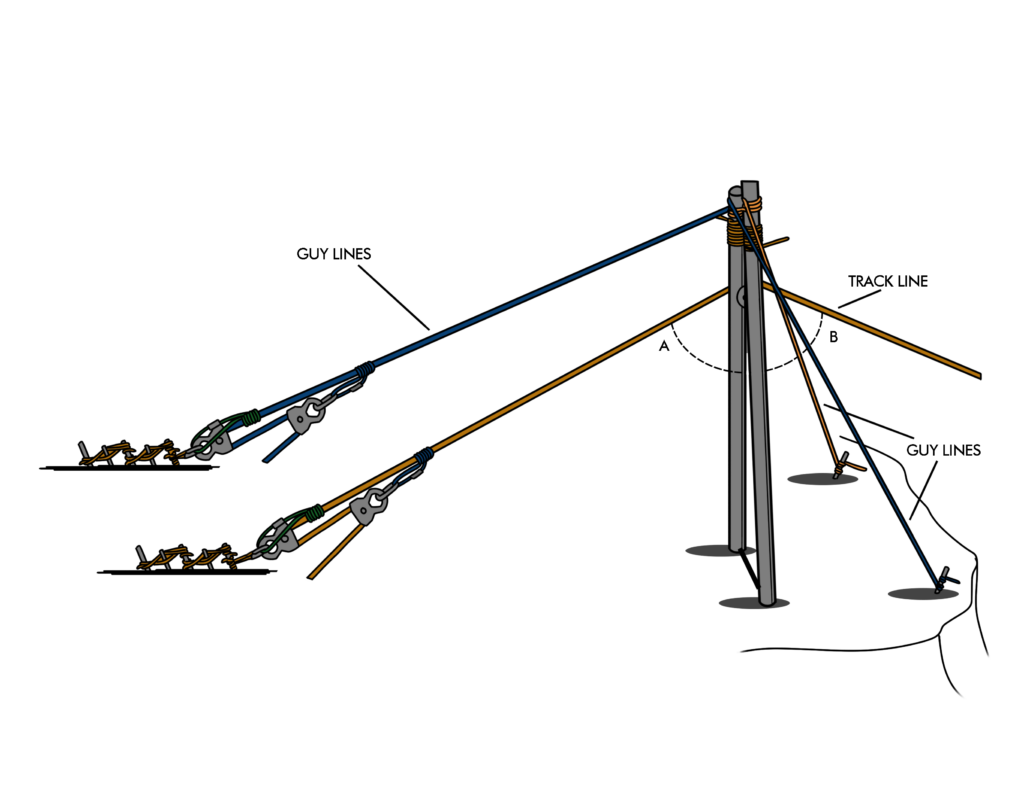

The gin pole is another traditional high directional method, using a single vertical timber for lifting loads.

How to Build a Timber Gin Pole:

- Select a Sturdy Timber:

- The pole should be straight, strong, and free from defects.

- Secure the Base:

- Anchor the base of the pole firmly near the edge of the rescue area.

- Attach a Pulley or Block at the Top:

- Use a rope pulley system to lift and lower loads through the top of the gin pole.

- Stabilize with Guy Lines:

- Run multiple guy lines from the top of the pole to anchor points to ensure stability.

Key Considerations for Timber High Directionals

When using wood structures for rescue operations, it’s essential to follow best practices to ensure safety and reliability:

1. Timber Quality:

- Ensure the wood is free from rot, cracks, and defects.

- Use hardwoods like oak or ash for better strength and durability.

2. Lashing Techniques:

- Proper lashing and knotting are essential for securing joints.

- Use round turn lashing for A-frames and secure guy lines with clove hitches or bowlines.

3. Stability:

- Implement guy lines to stabilize the structure.

- Regularly inspect the setup for signs of stress or movement during use.

Modern Alternative: Arizona Vortex (AZV)

While timber structures are effective, many modern rescue teams rely on the Arizona Vortex (AZV) for high directional setups. The AZV is a modular, adjustable system designed specifically for technical rescue operations.

Why the Arizona Vortex is Superior:

- Material:

- Made from T-6 aluminum, the AZV offers lightweight strength and durability.

- Configurations:

- Can be set up as a tripod, A-frame, or gin pole, making it highly versatile.

- Adjustability:

- Allows for precise height and angle adjustments, which are difficult to achieve with timber.

- Applications:

- Ideal for edge transitions, confined space rescues, and vertical lift systems.

For more details on the Arizona Vortex, visit Rescue Response Gear.

Combining Traditional and Modern Techniques

In many rescue scenarios, it’s beneficial to combine traditional timber methods with modern equipment to achieve the best results:

- Timber Structures in Remote Areas:

When specialized equipment isn’t available, timber A-frames or gin poles can be used as primary high directionals. - Modern Hardware Integration:

Incorporate modern pulleys, carabiners, and rigging plates with timber structures to enhance efficiency and safety. - Mechanical Advantage Systems:

Pair timber high directionals with 4:1 or 5:1 mechanical advantage systems to simplify lifting operations.

Challenges of Using Timber Structures

While timber structures can be effective, they present unique challenges:

| Challenge | Solution |

|---|---|

| Finding suitable timber | Select hardwoods and inspect thoroughly |

| Securing lashings | Use proper lashing techniques and wedges |

| Ensuring stability | Implement guy lines and regular inspections |

| Adapting to terrain | Combine timber structures with modern hardware |

Key Considerations for Timber High Directionals

When using wood structures for rescue operations, it’s essential to follow best practices to ensure safety and reliability:

- Timber Quality: Ensure the wood is free from rot, cracks, and defects.

- Lashing Techniques: Use proper lashing and knotting to secure joints.

- Stability: Implement guy lines to prevent movement and collapse.

Material Strength, Anchor Points, and Load Angles

Building a timber high directional isn’t just about construction techniques—you also need to account for material strength, anchor placement, and load angles to ensure your setup can safely handle the forces involved in rescue operations.

1. Material Strength

The timber you choose for your high directional must be capable of withstanding dynamic loads and shock forces encountered during rescue scenarios. Here are key guidelines to ensure the wood is structurally sound:

- Select Hardwood Species: Hardwoods like oak, ash, or hickory are preferable for their strength and durability. Avoid softwoods unless there is no alternative.

- Inspect for Defects: Carefully check the timber for cracks, knots, or rot that could weaken the structure.

- Assess Load Capacity: Make sure the timber is thick and straight enough to bear the anticipated loads, accounting for both static and dynamic forces.

2. Anchor Points

Anchor points are critical to the stability of any high directional system. Improperly configured anchors can lead to shifting, collapse, or system failure.

- Secure the Base: Ensure the base of the A-frame or gin pole is firmly anchored to prevent sliding or tipping.

- Use Natural Features: Whenever possible, tie off to trees, rocks, or other natural anchors to provide additional stability.

- Redundant Anchors: Implement multiple anchor points to reduce the risk of failure if one anchor point slips or breaks.

3. Angle of Load

The angle at which the load is applied to the high directional significantly impacts the stress on the timber. Improper angles can cause excessive lateral forces, increasing the risk of failure.

- Optimal Angle for A-Frames:

The angle between the legs of an A-frame should be between 60° and 70° for maximum stability. - Avoid Over-Compression:

If the angle is too narrow, it can cause excessive compressive forces on the timber legs, increasing the risk of buckling. - Manage Dynamic Loads:

Consider the potential swing or shock loads when lifting, and avoid placing unnecessary lateral strain on the structure.

Conclusion

Understanding both traditional timber-based high directionals and modern alternatives like the Arizona Vortex equips rescue teams to adapt to various scenarios. Timber structures offer a reliable, low-tech solution when modern equipment is unavailable, while tools like the AZV provide precision, adjustability, and ease of use.

By blending both traditional and modern approaches, rescue teams can enhance their adaptability, ensuring safe and efficient rescue operations in any environment.

Related Questions

- How can timber structures be adapted for high directional rescue operations?

- What are the challenges of using wood structures in rescue scenarios?

- Are there specific types of wood that are better suited for high directional rescue systems?

- How do you ensure the stability of wood structures during rescue operations?

- What are the safety considerations when using wood structures in high directional rescue?

Linking Strategy

Include links to the following Rigging Lab Academy articles and Rescue Response Gear product pages:

- Building Your Rescue Systems

- Twin Tension Rope Systems Explained

- Rescue Equipment Essentials

- Arizona Vortex (AZV)

Peace on your Days

Lance