Maintaining and Inspecting Rope Rescue Equipment: A Lifeline for Safety and Performance

In rope rescue operations, the reliability of your equipment is non-negotiable. Whether you’re responding to high-angle rescues, confined spaces, or swift water scenarios, the tools at your disposal must perform flawlessly. Maintaining and inspecting your gear is not just a task but a responsibility that directly impacts safety, efficiency, and success.

Regular inspections and proper maintenance ensure your equipment is always ready to handle the pressures of life-and-death scenarios. From ropes and harnesses to carabiners and pulleys, every piece must be in optimal condition. Neglecting this process risks more than gear failure—it compromises the safety of both rescuers and those being rescued.

The Foundations of Maintenance: Why It Matters

Rope rescue equipment is exposed to rigorous conditions, including friction, UV exposure, abrasion, and environmental contaminants like mud or chemicals. Without diligent care, even the most robust equipment can degrade over time.

Regular maintenance is crucial for:

- Prolonging the lifespan of equipment, reducing replacement costs.

- Ensuring compliance with NFPA and OSHA standards for operational readiness.

- Enhancing team confidence, knowing their tools won’t fail under pressure.

These benefits make an organized, systematic approach to equipment care indispensable for any rescue team.

Essential Practices for Equipment Maintenance and Inspection

1. Establish a Maintenance Program Every rescue team should develop a formalized equipment maintenance program. This program should include:

- Scheduled maintenance intervals, such as monthly and annual inspections.

- Emergency checks after high-stress operations or adverse conditions.

- A clear record-keeping system to document inspections, repairs, and retirements.

Pro Tip: Use a digital tracking system to log maintenance activities and stay ahead of upcoming inspections.

2. Inspection Techniques for Key Equipment

- Ropes: Look for abrasions, cuts, discoloration, or stiffness. Run your hands along the rope to detect unseen damage.

- Carabiners and Hardware: Check for rust, deformities, or compromised gates. Ensure smooth operation of locking mechanisms.

- Harnesses and Webbing: Inspect for frayed stitching, tears, or UV degradation. Pay special attention to high-stress points.

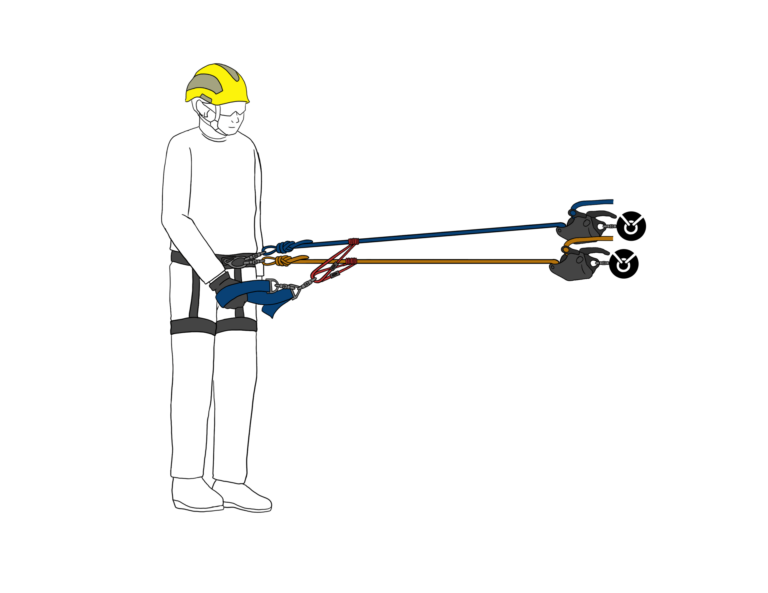

- Pulleys and Mechanical Devices: Verify smooth rotation of sheaves and check for debris inside moving parts.

Bullet List Example for Reference:

- Ropes: Abrasions, discoloration, stiffness.

- Carabiners: Rust, deformities, smooth gate operation.

3. Cleaning and Decontamination Rescue equipment often comes into contact with dirt, mud, oil, or chemicals. Proper cleaning can extend the life of your gear significantly:

- Ropes and Webbing: Wash with mild soap and water, avoiding harsh chemicals. Air dry away from direct sunlight.

- Hardware: Remove dirt and debris using a soft brush. Apply silicone-based lubricants sparingly to moving parts.

Knowing When to Retire Equipment

One of the most critical aspects of maintenance is recognizing when equipment has reached the end of its service life. Key considerations include:

- Manufacturer Guidelines: Always refer to the manufacturer’s specifications for retirement thresholds.

- Visible Damage: If any piece of equipment shows signs of wear or compromise that could affect performance, remove it immediately.

- Stress Events: Any equipment exposed to extreme forces or life-threatening conditions, such as falls or chemical exposure, should be retired even if it appears undamaged.

Important Reminder: NFPA 1983 provides guidance on the retirement of life safety equipment, emphasizing that no gear should be used beyond its recommended lifespan.

Organizing for Maintenance Success

Effective maintenance relies on organization. Create a streamlined system for storing, inspecting, and maintaining gear:

- Use clearly labeled storage bins to separate inspected gear from equipment awaiting review.

- Implement color-coded tags to indicate inspection status (e.g., green for ready, yellow for due, and red for retired).

- Establish a central hub where all equipment logs, manuals, and training materials are stored for easy access.

Collaborative Team Responsibility

Maintaining and inspecting rope rescue equipment is not a one-person job. Every team member should share responsibility for ensuring the integrity of the gear:

- Training: Educate your team on proper inspection techniques and common signs of wear.

- Accountability: Assign individuals to oversee specific gear categories, such as ropes or hardware.

- Collaboration: Encourage open communication about gear conditions and potential issues.

Closing the Loop: Continuous Improvement

Equipment maintenance is an evolving process. Regularly review your practices to incorporate lessons learned from past operations and stay updated on industry standards. Consider partnering with trusted vendors for expert advice on optimizing your gear cache.

By prioritizing equipment maintenance and inspections, rescue teams can maximize operational readiness and minimize the risk of failure. This dedication to excellence ensures the safety of both rescuers and the lives they aim to save.

Reference Links Included:

Peace on your Days

Lance