Rope Rescue Highline Systems and Rigging Techniques

Rope rescue and rigging highline systems are critical components of technical rescue operations, particularly in situations where victims or rescuers need to be moved vertically or horizontally across challenging terrain or obstacles. These systems are commonly used in wilderness search and rescue, industrial settings, and by first responders in various emergency scenarios. Here’s an overview of key concepts related to rope rescue and rigging highline systems:

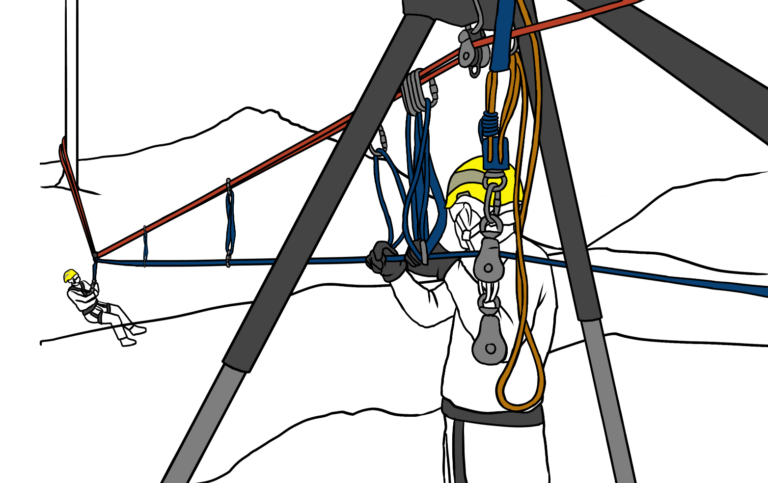

- Highline System: A highline system is a setup that allows for horizontal movement across a gap, such as a river, canyon, or other obstacles. It typically consists of two anchor points on either side of the gap, a tensioned rope or cable (highline), and a trolley or pulley system to traverse the rope. Highline systems are used to transport victims, equipment, or rescuers safely across otherwise impassable terrain.

- Anchor Points: The anchor points are secure and stable locations where ropes or cables are anchored. These points are crucial for the stability and safety of the highline system. Common anchor points include natural features like trees or rock formations, or artificial anchors like bolts and anchors designed for this purpose.

- Tensioned Rope/Cable: The rope or cable used for the highline system must be strong, dynamic, and capable of supporting the intended loads. It is typically tensioned to maintain the desired sag or height above the ground or water. Rigging devices like come-alongs or mechanical tensioning systems are often used to achieve the necessary tension.

- Trolley/Pulley System: A trolley or pulley system is used to attach to the rope or cable, allowing for smooth and controlled movement along the highline. These systems may include safety features like locking mechanisms to prevent unintended movement.

- Harnesses and Safety Gear: Individuals using highline systems should wear appropriate harnesses and safety gear, including helmets, gloves, and fall protection equipment. These are essential for their safety during rigging and traversing.

- Knots and Hitches: Rescuers often use various knots and hitches to secure ropes, create anchor points, and connect components of the highline system. Common knots and hitches include the figure-eight follow-through, clove hitch, bowline, and double fisherman’s knot.

- Rigging and Safety Checks: Before any highline operation, rigorous rigging and safety checks are performed. This includes inspecting all equipment, ensuring proper tension on the line, and confirming the integrity of anchor points. Continuous monitoring during the operation is essential to identify and address any issues promptly.

- Communication: Effective communication is vital during highline operations. Rescuers on both sides of the highline system need to coordinate their efforts, and hand signals or radios are often used for this purpose.

- Training and Certification: Personnel involved in rope rescue and rigging highline systems must undergo specialized training and certification. This training covers rigging techniques, equipment use, safety protocols, and rescue procedures.

- Situational Awareness: Maintaining situational awareness is crucial in rope rescue operations. Rescuers need to assess changing conditions, weather, and potential hazards continuously.

Overall, rope rescue and rigging highline systems require a high degree of skill, teamwork, and attention to safety. These systems are essential tools for rescuers to access and extricate individuals from challenging and remote locations safely. Training, practice, and adherence to safety standards are paramount for successful highline operations.

Highlines, alternatively known as telphers or Tyroleans, are specialized rope systems designed for transitioning personnel or gear between two designated points. These systems can be set up as a horizontal highline, where both endpoints are nearly on the same elevation plane, or as a sloping highline where the end points have significant height differential. This versatility makes highlines a valuable asset in rope rescue operations, as the ability to adjust to varying terrain and elevation can mean the difference between success and failure in critical rescue scenarios.

Rope rescue comes into its own when navigating challenging terrains like steep canyons or fast-flowing rivers. It’s also a real game-changer when you need to hover a load over tricky scrub or rocky landscapes where carrying a litter through would be a nightmare. Some rescue squads might shy away from rope rescue thinking it’s more time-consuming if you’re not au fait with the technique. But teams who’ve buckled down and mastered the ropes (pun intended!) have found it’s an absolute lifesaver, speeding up many a rescue mission.

When it comes to high lines, some rescue teams can be a bit wary due to fears of overloading the gear or anchor points and causing system failure. But hey, don’t sweat it – good training can easily mitigate this risk. And let’s face it, in certain situations, having a high line can be a game changer.

As you know, high lines come in two main flavors – Kootenay and Reeving. A Kootenay highline is a tensioned track line where your load hangs on pulleys and carabiners. The cool thing? You can lower the load midway just by easing off the track line tension. On the other hand, a reeving highline keeps the track line tensioned but lowers the load in mid-span using pulleys and extra ropes.

Track line – A “trackline” refers to a guiding rope or line that is strategically set up to assist rescuers in moving along a specific path or route. It serves as a safety measure and provides a controlled means for rescuers to traverse challenging terrain, such as cliffs, steep slopes, or other difficult-to-access areas. The trackline can be anchored securely at various points to ensure stability and safety while allowing rescuers to focus on their movements and tasks. It’s an essential component of rope rescue systems, enabling effective and controlled movement during rescue operations.

Static Anchor – a “static anchor” refers to a fixed and immovable point to which ropes are attached. This anchor point provides stability and support for various rope systems used in rescue operations. Unlike dynamic anchors that might move or shift, a static anchor remains stationary and secure, ensuring the safety of both rescuers and the individuals being rescued. Static anchors are critical for distributing forces evenly and preventing unexpected movement during the rigging and execution of rescue techniques. They are established using strong and reliable structures, such as trees, rock formations, or specially designed anchor points, to ensure the integrity of the rescue system.

Tensioning Anchor – A “tensioning anchor” refers to an anchor point that is used to apply tension to a rope system. This type of anchor is employed to tighten lines and create a controlled level of tension within the system. Tensioning anchors are essential for adjusting the setup, aligning ropes, and achieving the desired configuration for effective rescue operations.

Rescue scenarios often require specific rope tensions to ensure stability, balance, and controlled movement. Tensioning anchors might involve specialized equipment like pulleys, mechanical advantage systems, or friction devices to achieve the necessary tension in the rope lines. These anchors play a crucial role in fine-tuning the system’s geometry and maintaining the required forces for safe and efficient rescues.

Track Pulley – A “track pulley” is a specialized pulley designed to move along a rope while maintaining a low profile. This type of pulley is used to create efficient and controlled movement in various rope systems during rescue operations. The design of a track pulley allows it to glide smoothly along the rope without twisting or rotating, ensuring that the rope runs smoothly through the pulley.

Track pulleys are particularly useful in scenarios where rescuers need to navigate along a rope line or where mechanical advantage systems require precise movement. They are often used in conjunction with other components like carabiners, anchors, and ropes to create versatile and effective systems for hauling, lowering, or traversing in rope rescue situations. The ability to move smoothly along the rope makes track pulleys an essential tool for maintaining proper rope alignment and reducing friction, which in turn enhances the overall efficiency of the rescue operation.

Tensioning System – A “tensioning system” refers to a collection of components and techniques used to apply controlled tension or force to ropes within a rope rescue system. The purpose of a tensioning system is to create the desired level of tightness in ropes, lines, or webbing, which is crucial for maintaining stability, adjusting the configuration, and achieving the necessary mechanical advantage during rescue operations.

Tensioning systems can vary in complexity and design based on the specific needs of the rescue scenario. They might involve pulleys, mechanical advantage systems, specialized devices, and anchor points that collectively work to generate the desired tension in the ropes. These systems are used for tasks like adjusting line lengths, tightening ropes to achieve a secure setup, or creating the necessary forces for lifting or lowering rescuers or victims. The effective implementation of a tensioning system is vital for ensuring the safety and success of rope rescue operations.

Control Lines – A “control line” refers to a rope that is used to manage and control the movement of a load, rescuer, or other elements within a rescue system. Control lines play a crucial role in maintaining stability, adjusting the position of objects, and ensuring safe and controlled movement during various rescue operations.

Control lines are typically manipulated by rescuers to regulate the speed, direction, and position of the load being moved. They are often connected to mechanical advantage systems, pulleys, or other devices that allow rescuers to fine-tune the movement and prevent sudden or uncontrolled shifts. By applying tension or slack to the control line, rescuers can guide and direct loads along the desired path, facilitating precise and safe maneuvers during rope rescue scenarios.

Festoons – A “festoon” refers to a technique where a secondary rope or line is rigged in a loop or series of loops between the main rope and an anchor point. This technique is often used to create a smoother and more controlled movement of the main rope, especially when dealing with uneven terrain or obstacles.

The festooned rope acts as a buffer, absorbing any sudden shocks or changes in tension that might occur in the main line. It helps to prevent sudden jerks or jolts that could be dangerous to both rescuers and victims. Festooning is particularly useful when constructing highlines or long horizontal rope systems, as it enhances stability and reduces the risk of unexpected movements. This technique is an important element in creating safer and more efficient rope rescue and highline systems.

Messenger Line – A “messenger line” refers to a secondary line that is used to facilitate the pulling or guiding of another, usually larger, line. The messenger line serves as a means to thread or guide the main line through complex or hard-to-reach pathways, such as pulleys, anchors, or tight spaces.

The messenger line is often lighter and easier to maneuver than the main line, making it more suitable for navigating intricate rigging setups. Once the messenger line is in place, it can be used to pull or haul the main line along the desired route. This technique is particularly valuable in scenarios where the main line might be difficult to directly manipulate, allowing rescuers to precisely position and secure the main line for effective rope rescue or rigging operations.

Pilot Cord – A “pilot cord” refers to a lightweight rope or line that is used to guide and direct the movement of a heavier or more complex main line. It serves as a preliminary guide for threading the main line through tight spaces, pulleys, or complex rigging configurations. Normally 1-2 mm in diameter.

Pilot cord is typically easier to handle and maneuver compared to the main line, making it ideal for navigating intricate pathways. Once the pilot cord is threaded or guided through the desired route, it provides a clear path for the main line to follow. This technique is especially useful when setting up complex systems like highlines or when maneuvering ropes around obstacles, allowing rescuers to ensure proper alignment and reduce friction during rope rescue and rigging operations.

Set-Up and Considerations

Getting a high line up and running typically needs a rescue team on both ends, tying those anchors down. But hey, sometimes our brave rescuers can’t make it to the other side, right? When that happens, you might only have the person needing rescue or some other folks who aren’t trained for this stuff on the other side. If there are good anchors, like big ol’ trees, they could be told how to tie a high-strength knot or what we call a tensionless hitch for the static anchor… here’s hoping you won’t have to do that though!

The initial pass may not permit the establishment of a control line from the opposing side, thus constraining the belay to one side only. An evaluation of the potential risks and benefits can help ascertain if opting for a high line devoid of a full belay is the optimal choice for crossing, or if a different method could or should be applied. Upon reaching the other side, the first rescuer can string a control line and finalize the belay.

Elevating highline anchors is crucial to ensure adequate clearance for the load crossing the span’s edge. If required, you can route the track line through a large-diameter pulley at a higher level, and then secure it to a lower-level anchor. This approach might necessitate constructing an A-frame, which should be in place before tensioning the system. It’s important to note that the track line and control lines need to be sufficiently proximate for the festoons to connect, and managing these is a task that someone must undertake.

What are the System Safety Factors and Concerns?

In rope rescue and highline rigging systems, “system safety factors” refer to critical considerations taken into account to ensure the overall safety and reliability of the rigging setup. These factors play a pivotal role in maintaining the integrity of the system and minimizing the risks associated with rope rescue operations. Some key system safety factors include:

- Load Capacity: Rigging systems must be designed to handle the anticipated loads that may be imposed on them during rescue operations. This includes the combined weight of rescuers, equipment, and victims. Ensuring that the system can handle the expected loads without failure is paramount.

- Dynamic Loads: Rope rescue scenarios often involve dynamic forces due to movements, impacts, or shifts. Rigging systems should account for these dynamic loads and have sufficient redundancy to handle unexpected forces.

- Factor of Safety: A factor of safety involves designing the system to handle loads well beyond the anticipated forces. This additional margin accounts for uncertainties, unexpected events, and variations in real-world conditions.

- Material Strength: The strength of ropes, hardware, and anchor points must be thoroughly understood and matched to the loads they will bear. The weakest link in the system determines its overall strength.

- Angle Forces: Angles at which ropes intersect hardware or anchor points can significantly affect the forces within the system. Correct calculation and understanding of these angles are crucial to ensure load distribution.

- Friction and Heat: Friction between ropes and hardware can generate heat, potentially weakening the ropes over time. Adequate measures should be taken to reduce friction and prevent excessive heat buildup.

- Redundancy: Building in redundancy involves having backup systems or multiple anchor points in case one fails. This redundancy enhances safety by providing backup support in case of unexpected failures.

- Inspect and Maintenance: Regular inspection and maintenance of ropes, hardware, and anchor points are vital to identify wear, damage, or deterioration that might compromise the system’s safety.

- Environmental Factors: Consideration of environmental conditions such as weather, temperature, and terrain is essential as they can impact the integrity of the rigging system.

- Rescue Plan: A comprehensive rescue plan should be in place in case of any system failure. This plan outlines how to respond effectively to emergencies and minimize risks.

All these factors must be carefully evaluated and integrated into the design, setup, and operation of rope rescue and highline rigging systems to ensure the safety of both rescuers and victims.

Peace on your Days

Lance