Understanding the T-Method for Pulley Efficiency

In rope rescue and rigging systems, accurately analyzing mechanical advantage (MA) is critical for efficient operations and safety. The T-Method provides a systematic approach to evaluate pulley efficiency, taking into account friction and real-world variables. This method goes beyond theoretical calculations, allowing teams to determine the actual output of their systems with precision.

How the T-Method Works

The T-Method of analysis incorporates the following elements:

- Pulley Efficiency: Measures the difference between theoretical and actual output forces.

- Friction Analysis: Accounts for rotational and rope friction in pulleys.

- Cumulative Efficiency: Multiplies individual pulley efficiencies to determine the system’s total efficiency.

By applying the T-Method, rescue technicians can calculate the actual mechanical advantage (AMA) of their systems, ensuring accurate load predictions and optimal resource utilization.

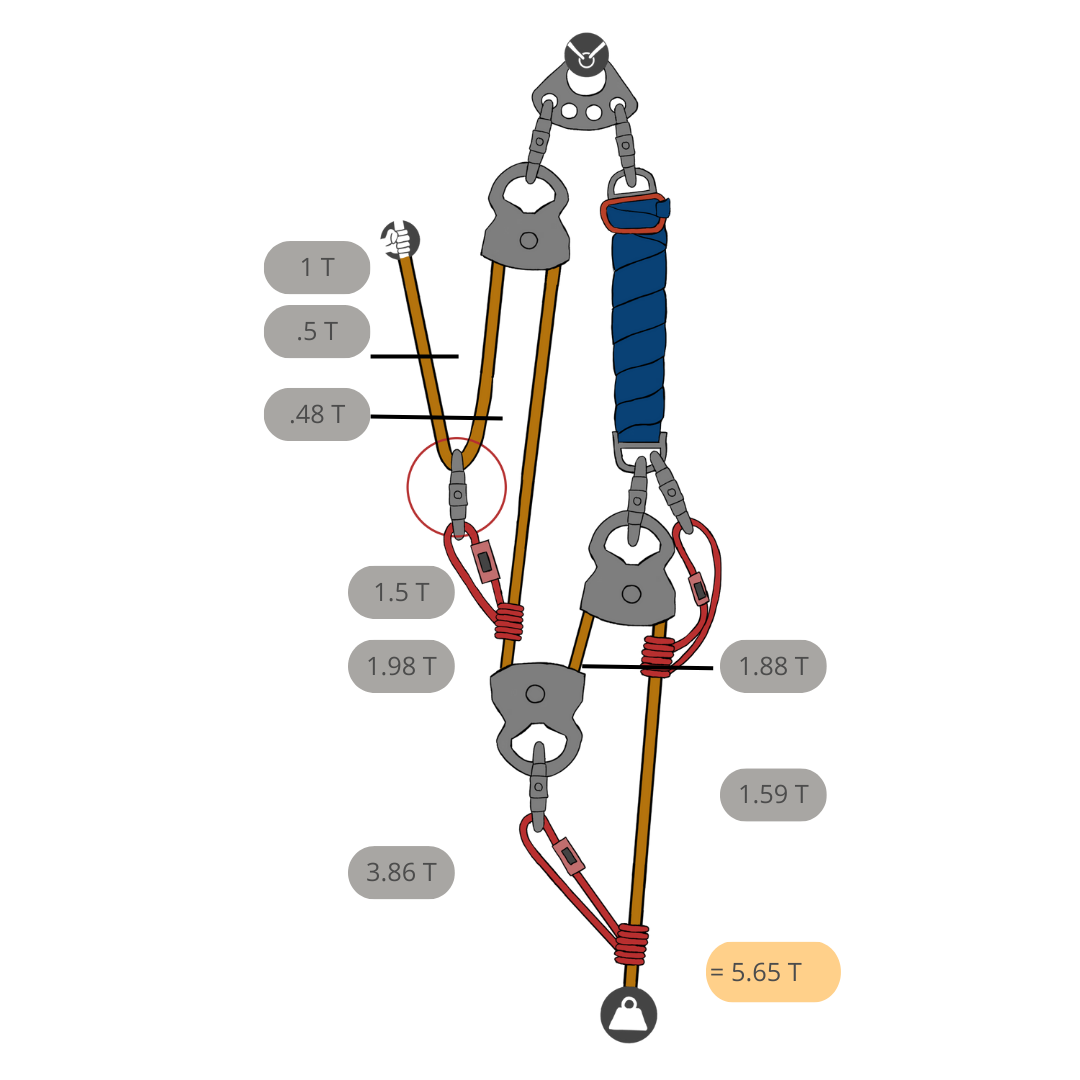

Determining Actual MA using T-Method

4 – .85 Efficient Pulleys 4 – .85 Efficient Pulleys |

4 – .95 Efficient Pulleys 4 – .95 Efficient Pulleys |

Best Place to Place Carabiners in a 9:1 MA as Determined Through T-Method

|

Carabiner-Pulley in the #2 Position |

Carabiner-Pulley in the #3 Position Carabiner-Pulley in the #3 Position |

Carabiner-Pulley in the #4 Position Carabiner-Pulley in the #4 Position |

Key Insights

1. Pulley Efficiency and Friction

Pulley friction originates from two primary sources:

- Rotational Force on the Sheave: Minimized using sealed ball bearings or Oilite bushings.

- Rope-to-Sheave Interaction: Rope friction coefficients can reduce efficiency by up to 15%.

2. Environmental and Human Factors

Environmental conditions such as uneven terrain, slopes, and obstructions can significantly impact system performance. The T-Method incorporates these variables into its analysis to ensure realistic and practical outcomes.

Human factors, including training levels and operator experience, are also integral. Proper planning, preparation, and education reduce the risk of system failure due to human error.

3. Efficiency in Complex Systems

As pulley systems become more complex, inefficiencies compound:

- A single change of direction can cause a 5% loss in efficiency.

- A 9:1 MA system with four pulleys may lose up to 20% efficiency.

Using high-quality components and maintaining equipment are crucial to mitigating these losses.

Practical Applications of the T-Method

- Determining AMA

For a system with four pulleys at 85% efficiency each:

- The total efficiency is 0.854=0.520.85^4 = 0.520.854=0.52.

- Divide the theoretical MA (9:1) by 0.52 to find the actual MA (~4.68:1).

- Optimal Pulley Placement

The placement of carabiners and pulleys affects the system’s overall performance. The T-Method provides insights into the best configurations for maximizing efficiency.

Why This Course Matters

The T-Method equips rescue technicians with the skills to:

- Design efficient hauling systems.

- Account for real-world variables in calculations.

- Reduce inefficiencies to maximize safety and effectiveness.

Ready to Learn More?

To master the T-Method and take your rigging and rescue skills to the next level.

Peace on your Days,

Lance