Continued: A Rescue Rope and Cord Overview

Rope construction has evolved to meet the demands of modern rescue operations, with various types of ropes designed for specific tasks, balancing strength, elongation, durability, and safety. Understanding these rope constructions helps technical rescue teams make informed choices for their specific needs.

Common Rope Constructions and Their Applications

There are several primary rope constructions used today, each offering unique characteristics that determine its suitability for different rescue scenarios:

1. Braided Rope

Braided rope is made of interwoven strands, resulting in:

- High Strength: Excellent durability for tasks involving heavy wear and abrasion.

- Smooth Surface: Easier handling and minimal snagging.

Best Use: General hauling tasks and situations requiring strong, flexible rope.

2. Twisted Rope

Twisted rope, also known as laid rope, consists of fibers twisted together to form strands. It offers:

- Flexibility: Easier to coil and manipulate in dynamic scenarios.

- Cost-Effectiveness: Typically less expensive than braided rope.

Best Use: Lightweight applications or tasks requiring agility.

3. Synthetic Fiber Rope

Modern synthetic ropes (e.g., nylon, polyester) excel in extreme environments due to their:

- Chemical Resistance: Suitable for hazardous material operations.

- Temperature Durability: Withstands both high and low extremes without breaking down.

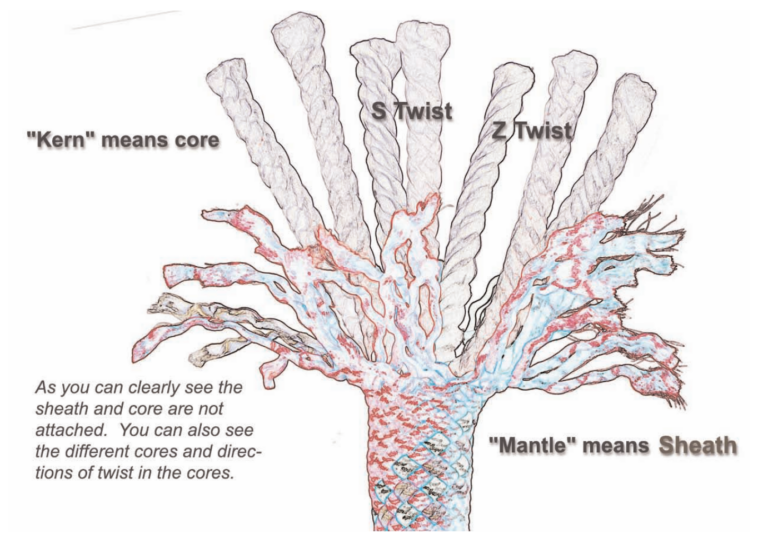

Kernmantle Rope: The Rescue Standard

Kernmantle rope is the most widely used rope in technical rescue due to its superior design. It consists of:

- Core (Kern): The parallel or braided fiber bundles provide 70%-90% of the rope’s strength.

- Sheath (Mantle): The woven outer layer protects the core from abrasion, UV exposure, and physical damage.

Manufacturers may braid or twist the core bundles to achieve the desired elongation and performance under load. For rescue operations, low-stretch kernmantle rope is the preferred choice due to its minimal elongation and high durability.

Rope Fiber Comparison Chart

To help identify the right rope material, here’s a comparison of common fibers:

| Fiber Type | Strength | Stretch | UV Resistance | Gravity | Melting Pt. | Cost |

|---|---|---|---|---|---|---|

| Nylon | High | High | Good | 1.14 | 210-254°C | Moderate |

| Polyester | High | Low | Good | 1.38 | 256°C | Moderate |

| Polypropylene | Low | Low | Poor | 0.91 | 170°C | Very Low |

| Polyethylene | Low | Low | Poor | 0.93 | 135°C | Very Low |

| Aramids | Very High | Very Low | Fair | 1.44 | 500°C | Very High |

| HMPE | Very High | Very Low | Fair | 0.96 | 135°C | Very High |

| LCAP | Very High | Very Low | Fair | 1.41 | 330°C | Very High |

The Process of Rope Construction

Rope manufacturing is a precise process that balances elongation, strength, and handling properties. There are three primary phases of construction:

- Core Creation

- The central core fibers, responsible for the majority of the rope’s strength, are twisted or braided.

- The mechanical elongation of the core determines how much stretch the rope has under load.

- Sheath Addition

- The sheath protects the core from damage, abrasion, and UV exposure.

- A tightly woven sheath improves durability and handling.

- Rope Finishing

- Rope ends are heat-sealed or whipped to prevent fraying and to ensure reliable anchoring.

The twisting process is critical for rope stability. Rope fibers are spun into yarns, which are twisted into strands. These strands are then counter-twisted to create the final rope, ensuring structural integrity.

- Z-Twist: The twist progresses to the right (right-handed rope).

- S-Twist: The twist progresses to the left (left-handed rope).

This counter-twisting holds the rope together, creating a stable and durable structure.

Specialized Rope Types for Rescue Operations

Dynamic Kernmantle Rope

- Designed for climbing and fall protection.

- Elastic core fibers provide shock absorption during falls.

Best Use: Rock climbing and operations where fall potential exists.

Static Kernmantle Rope

- Minimal elongation for controlled operations.

- Stiffer design with untwisted core fibers for hauling, rappelling, and confined space rescues.

Best Use: Technical rescue, rappelling, and hauling systems.

Braid-on-Braid Rope (Double Braid)

- Features a braided core and a braided sheath.

- High flexibility and strength but only 50% of the load is carried by the core.

Best Use: Specialty ropes like ladder halyards and water rescue throw lines.

Conclusion

Rescue rope construction is an intricate blend of engineering and practical design, tailored to meet the challenges of technical rescue. From kernmantle ropes used in rappelling to braid-on-braid ropes for specialty tasks, understanding the strengths, materials, and construction of rescue ropes ensures safety, efficiency, and success in the field.

For deeper insights into rescue rope applications, training, and performance, explore more at Rigging Lab Academy.

Title: Rescue Rope and Cord Construction

Keyphrase: Rescue Rope and Cord Construction

Meta Description: Learn about rescue rope and cord construction, including kernmantle ropes, fiber comparisons, and rope manufacturing processes for technical rescue teams.

Tags: rescue rope construction, kernmantle rope, static rope, dynamic rope, rope manufacturing, technical rope rescue, rope materials, braid-on-braid rope, search and rescue ropes

Slug: rescue-rope-and-cord-construction

Peace on Your Days

Lance