In the world of technical rigging and rescue, the need for innovative, adaptable systems has never been greater. Among these, the truck-based gin pole stands out as a versatile solution for operations requiring efficient, mobile high-directional systems. From bridge rescues to industrial lifting, this system offers a unique combination of portability, stability, and strength.

A truck-based gin pole integrates a monopod or high directional with a fire apparatus or utility vehicle, turning the vehicle into a rigging powerhouse. In this blog, we’ll explore its applications, setup, and safety considerations, along with insights to help you optimize its use.

The Concept of the Truck-Based Gin Pole

At its core, a truck-based gin pole transforms a vehicle into a mobile rigging station. By using the truck’s built-in anchor points and stabilizers, the gin pole becomes a high directional capable of lifting, lowering, and redirecting loads. This system is particularly advantageous in scenarios where traditional anchor setups are unavailable or impractical.

Whether it’s lowering a rescue load off a bridge or lifting industrial equipment, the truck-based gin pole proves its worth by offering mobility and efficiency in the field.

Why Choose a Truck-Based Gin Pole?

- Mobility: Quickly reposition the system for operations in multiple locations.

- Efficiency: Reduces setup time compared to standalone gin poles.

- Stability: Vehicle-integrated stabilizers keep the system secure during use.

- Flexibility: Adaptable to a wide range of scenarios, including confined spaces and industrial sites.

Applications: Bridging the Gap Between Rigging and Rescue

The truck-based gin pole excels in various operational settings. Here are some key examples:

- Bridge Rescues:

When lowering loads over a bridge edge, the gin pole provides a stable high directional, reducing rope friction and ensuring smooth transitions. - Industrial Operations:

For lifting heavy equipment, the gin pole’s strength and mobility make it an essential tool for construction or repair sites. - Utility and Maintenance Work:

Truck-mounted systems simplify moving heavy components like poles or transformers in utility scenarios. - Confined Space Entry:

In tight, restricted areas, the gin pole adapts easily, offering a reliable solution where static anchors are unavailable.

Learn more about confined space solutions in Planning Your Artificial High Directional.

How to Set Up a Truck-Based Gin Pole

To maximize the efficiency and safety of your truck-based gin pole, careful planning and proper setup are essential. Here’s a step-by-step overview:

1. Prepare the Vehicle

Start by parking the truck on stable ground and engaging all parking brakes. Deploy outriggers or stabilizers to eliminate movement during operation. Ensuring a solid foundation is critical, especially when dealing with heavy loads or uneven terrain.

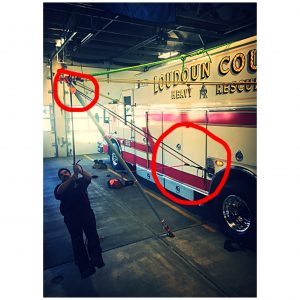

2. Secure the Gin Pole

Mount the gin pole securely to the truck’s designated anchor points, typically located on the vehicle’s frame. Attach guy lines to stabilize the pole and maintain balance under tension. For optimal stabilization, aim for equal tension across all guy lines.

3. Add Pulley Systems

Attach pulleys or directional blocks at the top of the gin pole to guide ropes efficiently. Ensure the pulleys are compatible with the load’s weight and rope diameter.

4. Rig the System

Use static kernmantle ropes for both the primary and backup lines to handle loads safely. Anchor these ropes to rigging plates or carabiners rated for the system’s intended forces.

Explore more about anchor systems in The Importance of Anchor Systems in Rescue Operations.

5. Conduct Pre-Operational Checks

Before live use, inspect all components, including ropes, pulleys, and anchor points, for wear or damage. Perform a trial lift or movement to ensure stability and control.

Safety Considerations

When working with a truck-based gin pole, safety must remain a top priority. Proper training and equipment inspections are vital to prevent accidents. Here are a few essential tips:

- Guy Line Management: Ensure all guy lines are tensioned equally to stabilize the gin pole. Uneven tension can cause instability or system failure.

- Force Alignment: Confirm that the resultant force on the directional pulley aligns with the gin pole’s compression axis to maintain structural stability.

- Load Limits: Always adhere to the system’s rated capacity and factor in a safety margin for additional loads.

Conclusion: Mobility and Power in One System

The truck-based gin pole is a game-changer for rigging and rescue professionals. By combining mobility, strength, and adaptability, it offers unparalleled versatility in the field. Whether you’re tackling bridge rescues, confined space entries, or industrial lifting, mastering the use of this system will elevate your capabilities and ensure safety for both your team and the loads you handle.

Peace on your Days

Lance